Background

Background

Day to day operation of a nuclear power, chemical processing or industrial plant requires continuous monitoring, checking and adjusting of the numerous components that enable the plant to operate safely and efficiently. When issues arise or problems occur the question becomes one of what to do.

Detailed computer codes, hand calculations, separate effects testing and engineering judgment are usually the tools of choice but not necessarily practical when schedules are tight and analysis via computer codes is either impossible or extremely difficult. In these situations, each hour lost costs money. A practical solution is to perform a scaled or full-sized test that replicates the exact set of conditions that are of concern.

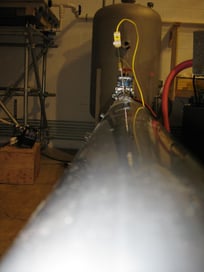

Fauske & Associates, LLC (FAI) has a proven reputation for performing these types of projects and a long history of loyal repeat customers in  this area. Our state-of-the-art engineering capabilities, experimental laboratory and support structure enable us to quickly and cost-effectively offer creative solutions to meet both acute and generic plant improvement testing needs. We regularly work with high and low pressure: steam (both saturated and

this area. Our state-of-the-art engineering capabilities, experimental laboratory and support structure enable us to quickly and cost-effectively offer creative solutions to meet both acute and generic plant improvement testing needs. We regularly work with high and low pressure: steam (both saturated and