Fire Protection Assessment and Engineering

FAI reviews risk assessment findings and determines if there are recommendations and next steps for fire protection. This analysis includes the re-baselining of fire areas to support a fire hazard analysis (FHA). The product is an overall matrix to address audit findings, risk assessment findings and open recommendations.

FAI reviews risk assessment findings and determines if there are recommendations and next steps for fire protection. This analysis includes the re-baselining of fire areas to support a fire hazard analysis (FHA). The product is an overall matrix to address audit findings, risk assessment findings and open recommendations.Services Provided

Supporting Software

OSHA requires that employers implement and document an

Fauske & Associates, LLC (FAI) has a highly qualified staff of electrical engineers who can assess and make recommendations to mitigate risk associated with electrical hazards in your workplace such as shock and arc flash. Key components of the FAI process are as follows:

Dynamic Mechanical Analysis is a state-of-the-art technique for understanding how the mechanical properties of a material behave as a function of time, temperature and frequency. Fauske & Associates, LLC (FAI) uses this effective method for characterizing the viscoelastic behavior of plastics, rubbers, and other polymeric materials.

What can be characterized by DMA:

What can be characterized by DMA: properties as a function of frequency, while

properties as a function of frequency, while held constant, and the viscoelastic properties are monitored as % strain or the stress is varied. This mode is primarily used to identify the Linear Viscoelastic Range (LVR).

held constant, and the viscoelastic properties are monitored as % strain or the stress is varied. This mode is primarily used to identify the Linear Viscoelastic Range (LVR). as a function of time. In stress relaxation, the strain is held constant and the stress is monitored vs. time.

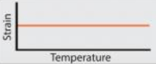

as a function of time. In stress relaxation, the strain is held constant and the stress is monitored vs. time. This mode is used to generate stress/strain plots to obtain Young's Modulus. Alternatively, stress can be held constant with a temperature ramp while strain is monitored.

This mode is used to generate stress/strain plots to obtain Young's Modulus. Alternatively, stress can be held constant with a temperature ramp while strain is monitored. sostrain can be used to assess shrinkage force in films and fibers.

sostrain can be used to assess shrinkage force in films and fibers.