Water Hammer Solutions - Background

Water hammer events are transmitted through the system at the speed of sound as applicable to the fluid-pipe combination (speed of sound varies with the density of the fluid). For water in a steel pipe, this is essentially the speed of sound in water (~4600 ft/s or 1400 m/s which is close to 1 mile/s). With this high transmission velocity, pipe segments are loaded in a highly transient manner causing them to shake. As a consequence, significant dynamic loads can be transmitted to the piping supports as well as the system components, i.e. valves, instrumentation, etc.

A structured approach to addressing water hammer solutions provides an efficient and cost effective and safe solution to address your water hammer issues.

Our expert team of engineers has extensive experience addressing and resolving various types of water hammer issues utilizing the following:

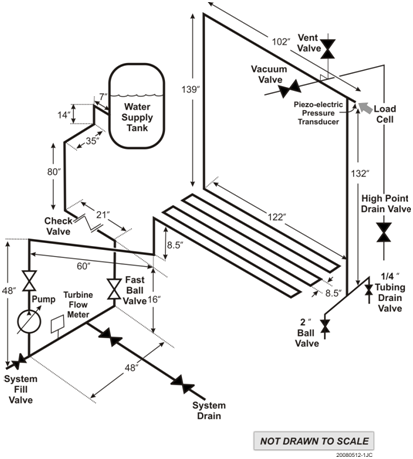

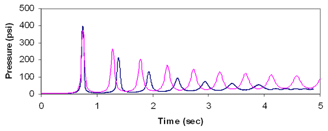

Our experimental facilities are designed to conduct non condensable gas-water or steam-water water hammer tests simulating conditions of interest in plants including those situations where a non condensable gas volume is formed in the pump discharge piping. Water hammer pressures are measured during the experiments and translated to plant conditions. This data can be used to set the limits of acceptable gas accumulation. Tests are conducted in an extended length piping configuration of the plant system and most importantly, the tests are run for a range of initial void sizes in the piping high point.

Our experts have experience testing multiple components at our facilities including: