DIERS Methodology Consulting

Fauske & Associates (FAI) was the principal research contractor for the Design Institute for Emergency Relief Systems (DIERS), an extensive R & D program sponsored by those 29 companies under the auspices of AIChE and completed in 1985. Company founder, Dr. Hans K. Fauske served as the principal investigator and overall technical leader of the DIERS research project. A primary purpose of that effort was the evaluation of emergency relief vent requirements, including energy and gas release rates for systems under upset conditions and the effect of two-phase flow on the emergency discharge process.

Fauske & Associates (FAI) has updated our DIERS emergency relief sizing tools with FERST software powered by CHEMCAD. FERST is a complete package that merges practical and easy-to-use methods, from our PrEVentTM (Practical Emergency Vent Sizing) software, with the material property, thermodynamics, and software development expertise of ChemstationsTM. FERST also enables the direct use of measured temperature rise rates from low Φ-factor adiabatic calorimetry (e.g., the VSP2 and ARSST) for dynamic simulation, similar to our legacy VSDS (Vent Sizing Dynamic Simulation) software.

FAI uses the DIERS-based VSP2™ and ARSST™ calorimeters to characterize reactive chemical systems and design emergency pressure relief systems. Both instruments provide vent sizing data that are directly applicable to the process scale (directly scalable) which is generally a much easier and more reliable approach than mathematical correction for thermal inertia and kinetic modeling of runaway chemistry.

The purposes of DIERS is to:

- Reduce the frequency, severity, and consequences of pressure producing accidents

- Develop new techniques which will improve the design of emergency relief systems

DIERS Consulting Services

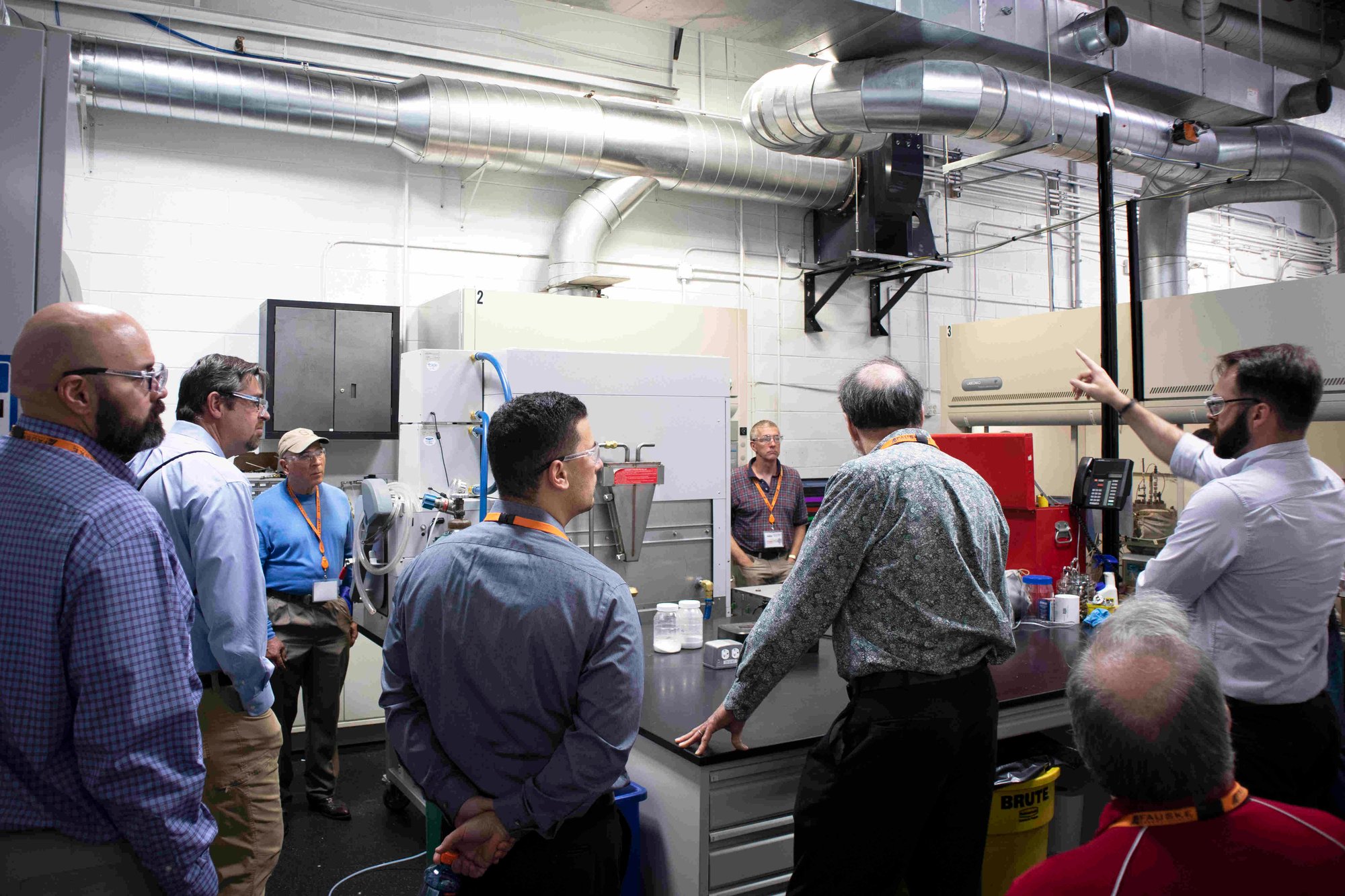

Relief System Design Training

Fauske & Associates proudly provides training and regularly published articles and blogs on these topics. The popular Relief System Design Course is generally taught over two or three days.

Unlike other emergency vent sizing course, this curriculum includes simplified calculation methods capable of giving safe – but not overly conservative relief system designs, with an emphasis on reactive chemistries and the role of two-phase flow.

Benchmarking of these methods is illustrated with incidents and available plant data. Utilization of methods and equations is demonstrated through practical design examples, covering vapor, gassy, and hybrid systems. Our FERST software is used to perform detailed calculations using DIERS methodology.

Attendees will participate in group workshops and complete an independent quiz at the end of the course to ensure comprehension of the material. Includes a laboratory session to demonstrate experimental techniques.

Course Schedule

Day 1

- Introduction to Vent Sizing and Case Study

- Vent Sizing Fundamentals

- Codes and Standards Explanation

- History for DIERS

- Tow-Phase Flow Considerations

- Experimental Considerations

- Vent Sizing Based on All Gas or Vapor Venting

Day 2

- Vapor System Vent Sizing

- Gassy System Vent Sizing

- Hybrid System Vents Sizing

- Simplified Two-Phase Flow Methods for Vapor, Hybrid and Gassy Systems

- Non-Reactive Fire Sizing

Day 3

- Stable Relief valve Operation

- Discharge Coefficient Evaluation

- Containment and Disposal Considerations

- Lab Demonstrations

Learning Outcomes

- Understand up to date DIERS vent sizing methodologies and models, as well as the role of single and two-phase flow in venting behavior

- Perform vent sizing calculations using the correct models and methodologies

- Understand and apply adiabatic calorimetry data

- Apply hands-on techniques and “rules of thumb” to ensure that realistic vessel and vent size conditions are specified

More on the ARSST and the VSP2

ARSST

A fast "minimum best practice" solution that is particularly well suited for energetic gas-generating systems, situations with limited sample quantities, for material that is incompatible with metal, and for quickly screening for unknown adverse reactions. Data are directly applicable to vent sizing and thermal stability analysis. Normally run as an open-cell test, with vaporization suppressed by imposed inert gas overpressure.

Learn more about ARSST

VSP2

Considered to be "available best practice" this versatile instrument is well-suited for simulating a broad range of abnormal process "upset" conditions to collect directly scalable data suitable for vent sizing. Provides superior mixing and continuous vapor pressure data in a closed cell, ideal for vapor pressure dominated systems. Scale lends itself to more complex simulations than can be done in the ARSST (for example, metered dosing or addition of small catalyst charges or suspensions/emulsions). Data are directly applicable to vent sizing and thermal stability analysis. Normally run as a closed cell test with active pressure balancing, but often run as an open cell test and can be used for blowdown testing to determine two-phase flow regime. Can also be used for battery testing.

Learn more about VSP2