Background

Structural engineering is an important field of engineering that deals with the integrity of objects such as plant components or structures. Fauske and Associates, LLC (FAI) employs several structural engineers that serve the industry by performing analytical assessments, experiments, walkdowns or numerical modeling. We specialize in supporting industrial process facilities and power plants.

In plants, the structural challenges are often related to pressure, temperature and dynamic forces. An example is the seismic adequacy of piping or components under power operation. FAI engineers perform seismic walkdowns on a regular basis to screen for the seismic adequacy of systems. We are able to follow industry guidelines such as EPRI 1019199 “Experience-Based Seismic Verification Guidelines for Piping and Tubing”. Alternatively, we have developed our own seismic screening methodology which provides an even more cost effective and conservative assessment approach. Several of our engineers and contractors have undergone professional seismic training which also allows us to assess safety-related electrical components such as instrumentation and control components etc.

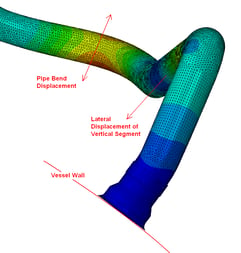

As we are supporting plant modernization and power uprate projects we have to utilize all facets of structural engineering. We have seen an increasing demand for vibration analyses, for example. FAI has the know-how to effectively study the cause of the vibration and to propose solutions for elimination or mitigation. Our engineers are available for on-site support which includes measurement, troubleshooting, and root cause analysis in a team setting together with the client.

Proper application of structural engineering expertise can help mitigate issues by ensuring that the plant and components are properly engineered. This will avoid machinery breakdown and costly plant outages. We strive to support our customers to achieve a safer and more efficient work environment along with enhanced plant durability.

FAI has a broad range of expertise in this area gained from several projects worldwide. We are able to provide a one-stop-resource for structural engineering issues including analyzing a problem, engineering a solution, verification, as well as oversight of fabrication and installation, as required.

Proper application of structural engineering methodology can help mitigate issues by ensuring that the plant and components are properly  engineered from the outset and machinery breakdown and extended plant outages are avoided. This results in a safer and more efficient facility and work environment along with enhanced durability.

engineered from the outset and machinery breakdown and extended plant outages are avoided. This results in a safer and more efficient facility and work environment along with enhanced durability.

Fauske & Associates, LLC (FAI) has a broad range of expertise in this area gained from working on several projects that involved a combination of structural integrity and mechanical vibration. Analytically obtained solutions are often backed up with experiments and software solutions.

FAI is able to provide a one-stop-resource for structural engineering issues including analyzing a concern, engineering a solution and then overseeing fabrication and installation of components as required.