Arc Flash

By Venky Viswanathan, Principal Electrical Engineer, Fauske & Associates

Electrical accidents occur all too often and in many industries. One very serious type of accident is called Arc Flash.

What is Arc Flash?

Arc Flash is the unintended flow of electric current through air from one conductor to another or from one conductor to ground. Arc flash releases extremely high amounts of energy in the form of intense heat (above 35,000oF), light and sound (around 140 dB or more), creating arc blast wave (pressure upwards of 2,000 lbs/sq.ft), involving flying objects (molten metal and projectiles from the electrical equipment), fumes ( vaporized metal) and fire.

Arc Flash hazard is defined as a source of possible injury or damage to health associated with the release of energy caused by an electric arc. [NFPA 70E Art 100]

Injury caused by an arc flash is a function of the proximity of the workers to the source of hazard, the fault current and the duration of time for which the arc persists.

Example of an Arc Flash Incident

Two technicians were troubleshooting a 480V breaker that would not close. The breaker was located in a cabinet that was energized. The cause of the problem was determined to be misalignment and tool used to evaluate the misalignment was dropped by accident and it was lodged between a live phase moving contact and the breaker support brace resulting in an arc flash.

The arc flash damaged the breaker cabinet, and splattered material in the surrounding area. The technician in close proximity to the cabinet was injured and the second worker was not harmed as he was outside the arc flash boundary.

Photograph of an arc flash explosion (unrelated to the incident described above).

This Photo by Unknown Author is licensed under CC BY-SA-NC

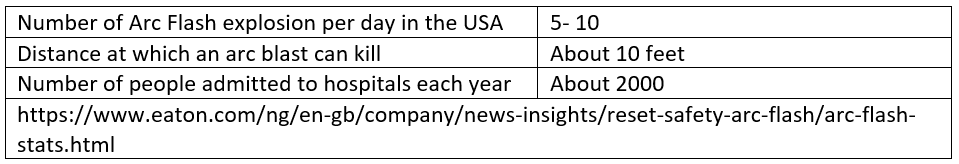

Arc Flash by the Numbers

Reference Standards

Arc flash studies are based on IEEE 1584 and NFPA 70E.

IEEE 1584 provides a mathematical model to determine the arc-flash hazard distance and the incident energy to which workers could be exposed during their work on or near energized electrical equipment.

NFPA 70E establishes safety processes that use policies, procedures, and program controls to reduce the risk associated with the use of electricity to an acceptable level. [NFPA 70E Fact Sheet]

What Causes Arc Flash

Typically arc flash incidents are caused by faulty installation, poorly maintained disconnect switches and circuit breakers, presence of dust, debris and foreign objects, corrosion, insulation failure, loose connections, condensation, carelessness such as dropping tools or tools left behind after installation/maintenance.

How to Protect Against Arc Flash

Protection against arc flash can be achieved by one or more of the following methods:

- Safety in Design

- Power system / arc flash studies using industry standard software such as ETAP, SKM or equivalent.

- Design power distribution networks to reduce the available fault current.

- Use of protective relays to reduce the duration for which the fault persists.

- Use of arc resistant switchgears and motor control centers.

- Incorporating remote rack-in /rack-out, closing/opening capabilities.

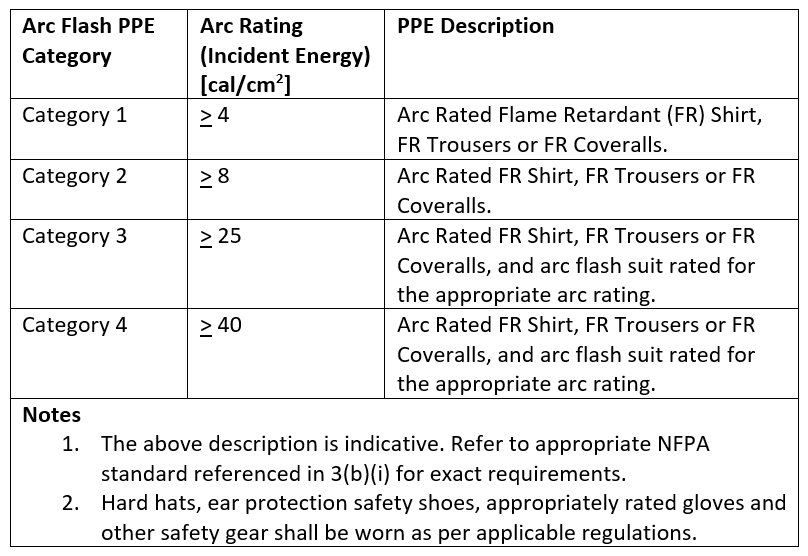

- Personal Protective Equipment (PPE)

- Personal Protective Equipment (PPE) shall be selected in accordance with Article 130, Table 130.7(C)(15)(c) of NFPA 70E.

- Arc Flash PPE requirements are summarized as noted below:

- Work Practices

- Pre-Job Briefing

- A discussion between the crew, supervisor, and other stakeholders such as Safety personnel, operators etc., before starting a particular task. In general, the briefing covers the scope of work, execution plan, safety requirements such as PPE, energy isolation points etc. The intent is to make the crew and supervisors aware of the scope of work, the risks, safety requirements required to execute a task in a safe manner.

- Job Hazard Analysis

- A job hazard analysis is a technique that focuses on job tasks as a way to identify hazards before they occur. It focuses on the relationship between the worker, the task, the tools, and the work environment. Ideally, after you identify uncontrolled hazards, you will take steps to eliminate or reduce them to an acceptable risk level [ OSHA 3071 Job Hazard Analysis].

- Other Practices

- Other practices such as Lock Out Tag Out (LOTO), de-energizing the appropriate buses are typically followed.

- Pre-Job Briefing

Labeling and Identification

- All electrical equipment such as panel boards, switchboards, switchgears, motor control centers, control panels, disconnect switches and transformers rated 50V and above shall be evaluated for arc flash and appropriately labeled.

- Arc flash calculations performed using software tools such as ETAP®, SKM or similar.

- The arc flash labels shall be permanently affixed on the equipment and shall have the following data points as a minimum to comply with OSHA and NFPA requirements.

- Danger or Warning header

- Danger in red background for voltages 600V and above

- Warning in orange background for voltages below 600V.

- Incident Energy

- The amount of thermal energy impressed on a surface, a certain distance from the source, generated during an electrical arc event, typically expressed in cal/cm2.[NFPA 70E, Art 100]

- Min. Arc Rating

- The value attributed to materials that describes their performance to exposure to an electrical arc discharge. The article of clothing or other PPE should be rated for the Arc Rating for the particular equipment.

- Arc Flash Boundary

- When an arc flash exists, an approach limit from an arc source at which incident energy equals 1.2 cal/cm2 (5J/cm2). A second degree burn on unprotected skin is likely to occur at an exposure of 1.2 cal/cm2 (5J/cm2). [NFPA 70E Art 100]

- Personal Protective Equipment (PPE)

- Refer to section 6(b)

- Limited Approach and Restricted Approach

- Limited Approach- An approach limit at a distance from an exposed energized electrical conductor or a circuit part within which a shock hazard exists. [NFPA 70E, Art 100]

- Restricted Approach-An approach limit at a distance from an exposed energized electrical conductor or circuit part within which there is an increased likelihood of electric shock due to electrical arc-over combined with inadvertent movement [NFPA 70E, Art 100]

- Shock Risk or Hazard

- A source of possible injury or damage to health associated with current through the body caused by contact or approach to exposed energized electrical conductors or circuits. Represented by system voltage of the equipment.

- Danger or Warning header

Best Practices

- Ensure that power system studies are performed by qualified personnel and the same is reviewed and updated when changes such as addition and deletion of loads are made to the power distribution system.

- Perform periodic audits to ensure that arc flash labels affixed on equipment are current, and readable.

- Follow good maintenance practices

- Pre-job briefings and Job hazard analysis

- Follow a rigorous lock out tag out policy

Conclusion

As explained, arc flash is a dangerous phenomenon which can cause significant damage to people and property. The same can be mitigated by performing system studies and adopting safe work practices. Fauske and associates have the expertise, experience, and capabilities necessary to perform power system studies and audits as applicable to arc flash. Please contact Venky Viswanathan, Principal Electrical Engineer at venky.viswanathan@westinghouse.com, for further details.

Reference

NFPA 70E Standard for Electrical Safety in the Workplace