Blast Analysis and Design Capabilities

Background

Emergency preparedness experts recognize the importance of structural protection against accidental and intentionally malicious blast loads. Structural integrity during an explosion is a way to mitigate the potentially catastrophic consequences from an explosion, whether due to industrial accidents or other destructive events. Increased reliance on power from hydrogen, natural gas, and battery energy storage means there is more potential for explosions in more places.

The hazards testing laboratory at Fauske & Associates (FAI) is a state-of-the-art facility for developing data on the explosion potential of materials, including dust, vapor, battery off-gas, and condensed phase materials such as organic/nitrate mixtures. Since 1980 FAI has provided critical process safety testing and consulting services to the chemical industry as well as to DOE contractors, but also has experience in blast analysis, for example due to failed natural gas or hydrogen piping at chemical processing and storage facilities. FAI, as a wholly owned subsidiary of Westinghouse Electric Company, is well-positioned to provide full-scope blast analysis and design capability to address needs of our industrial clients.

Description

Blast analysis requires a good understanding of the blast phenomenon and the dynamic response of structural elements, and there are a number of tools and techniques available as well as relevant codes and standards to consider. Areas where this expertise has been applied include:

- Blast design for critical facilities such as nuclear power plants, industrial sites, and military bases

- Design of blast mitigation strategies such as barriers and enclosures

- Design and analysis of buildings to resist progressive collapse

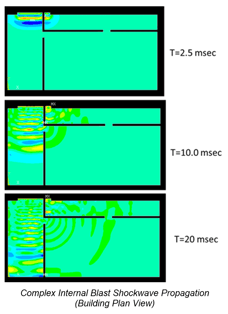

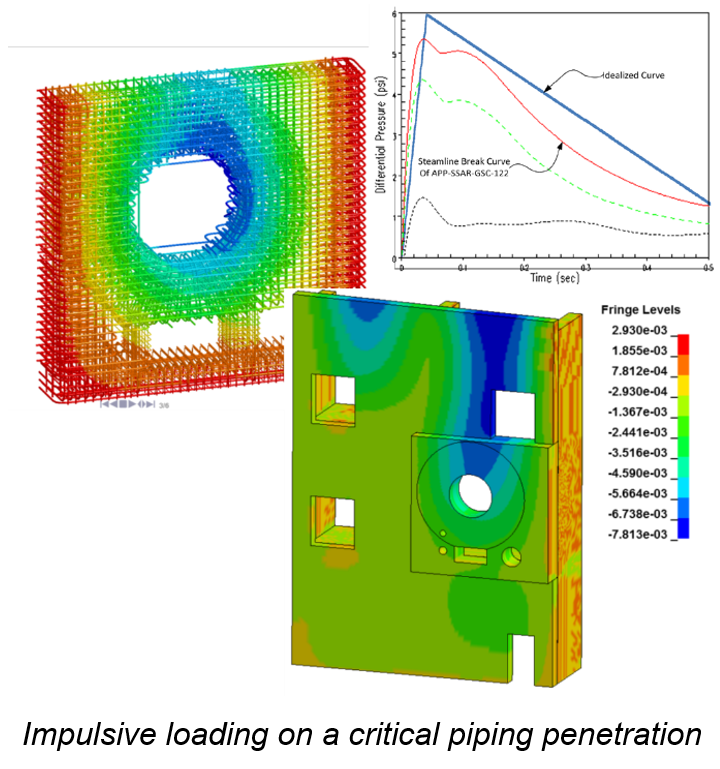

- Dynamic and non-linear analysis (3D ANSYS®/LS-DYNA®/ABAQUS®) of concrete, steel, and composite structures subjected to blast and impulsive effects

- Blast fragmentation and effects on structures and components

- Shock and vibration effects on building components and equipment

Benefits

Our team integrates its expertise in structural design, analysis, and testing to develop creative solutions for tough industry challenges. We provide high-quality products in conformance with industry codes and standards, satisfying strict internal QA processes, as well as ISO 9001 requirements. Experience in the design and analysis of nuclear-grade structures and components underpins our unique qualification to solve diverse blast analysis problems.

We are proud to offer

- Robust blast designs that are optimized for performance and economical to fabricate and construct

- Access to experts with extensive experience in civil, structural, and blast-related design and analysis

- Confidence that designs will satisfy all relevant code provisions

- Assurance that perform our work to a high-level of quality

- Confidence that final design will perform as intended under extreme blast events

Experience

We have a broad range of blast design and analysis experience. Recent projects include:

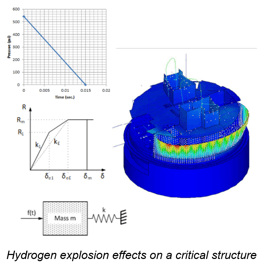

Hydrogen Explosion Evaluation (2019-2020)

Our team performed an evaluation of effects of a hydrogen gas explosion. The gas explosion was postulated to occur in a safety-related storage tank. Our experts characterized the blast pressures and assessed the effect on integrity of the storage tank.

Containment Vessel Over-pressurization Effects (2019-2020)

Evaluation of the effects of postulated rupture of a large containment vessel was performed. The evaluation focused on shockwave effects on nearby building structures and occupants. Our experts used a combination of simplified and complex analysis tools to evaluate the safety of the building.

Large Commercial Headquarters Building (2015-2017)

Our blast experts have experience in the blast design and analysis of critical commercial building structures. One example is a large international project, which involved developing a design basis threat and evaluating primary and secondary building structural elements for blast effects and progressive collapse potential.

Critical Manufacturing Facility (2014)

Our expertise also includes the evaluation of existing critical building structures subjected to accidental explosions. An example application is evaluating the effects of flammable gas leak at an automotive manufacturing facility. Due to the critical function of the facility, a blast analysis was performed to confirm adequate design of the explosion venting.

Military Testing Facility Design (2010-2012)

Our experts have experience in blast protection design of critical military facilities. Example projects include the blast design of a military testing facility and state-of-art dynamic analysis to support blast testing of key building elements (e.g., façade/curtainwall components, anchorages, and ventilation openings).

Contact Us

FAI has a long history of providing innovative solutions for specialized customer needs to meet code, regulatory, and other unique requirements. We have the expertise to develop, plan, and perform state-of-the-art analysis and the know-how to implement practical solutions. For more information on our blast analysis services or to contact a technical expert please email us at info@fauske.com.