Experimental Explosion Lecture and Demo ExElect Oct. 26 and Beyond

Crackling flames. The boom of exploding particles. The acrid smell of sulphur . . .

"Once you experience a live explosion, you will never forget it. You walk away with a healthy respect for the potential hazards in your workplace. And, a better understanding of how to prevent these accidents from happening in the first place." - Simon Hans Neimann, Manager of Process Safety Services, Fauske & Associates The Netherlands.

As part of an employee safety program, personnel who work around chemicals, gases and other materials should attend one one of these events. Technicians, supervisors, engineers, quality managers or safety, health and environmental managers at manufacturing plants and so on, should attend one of these events. Staff who formulate policy, implement plans or influence procedures should attend one of these events. You get the idea -

This is a short course demonstrating experiments as part of a possible safety event. Whether a kinetic, visual/spatial or verbal learner, ExElect provides an unforgettable educational experience by providing live demonstrations of real explosions in a lab environment. Attendees are actively involved in sessions. Called "a very effective way to raise awareness of explosive materials", past participants say demonstration "woke them up to the risks in their workplace and made a very deep impression".

Included:

- Physical and chemical explosions

- What happens when a pressurized liquid goes above its boiling point

- How different kinds of vapours behave under different conditions

- What an implosion looks like

- A dust explosion

- Complies with European directives for occupational safety education (certificate provided)

At the end of the course, particpants will have a clear understanding of the risks involved in working with flammable or explosive materials. Particpants can identify sources of ignition, the influence of geometry, confinement and other environmental risk factors. Learners will also know what safety precautions to take to prevent explosive incidents.

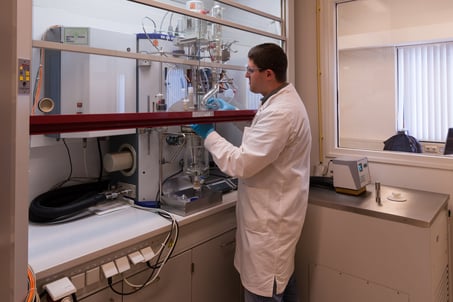

ExELect is a scalable portfolio of demonstrations, carried out at any location with the proper facilities. Courses are provided in 2 and 4 hour options as well as customizeable on site. However, our new lab - Fauske & Associates - the Netherlands, is providing a course on Wednesday, October 26 at Building G122-94, Room 94-2 301 Urmonderbaan 22, 6167 RD Geleen The Netherlands. Please contact Jeff Griffin, Director of Business Development +1 630 470 7168; griffin@fauske.com or Simon Hans Niemann, Manager of Process Safety Services +31 (0)6 1034 1550; niemann@fauske.com