One of the largest causes for loss in process industries for both equipment and life is fire. The sheer volume and frequency of use of flammable and combustible liquids and gases handled worldwide implies that the risk of industrial accidents is great. Safe processing requires understanding and quantifying these risks by obtaining the necessary safety data, which include things like flash point, flammability limits, and minimum ignition energy, for example.

One of the largest causes for loss in process industries for both equipment and life is fire. The sheer volume and frequency of use of flammable and combustible liquids and gases handled worldwide implies that the risk of industrial accidents is great. Safe processing requires understanding and quantifying these risks by obtaining the necessary safety data, which include things like flash point, flammability limits, and minimum ignition energy, for example.

As industrial process designs have evolved to take advantage of efficiencies at higher pressures and temperatures, the data requirements have evolved as well. To support data collection under more challenging test conditions Fauske & Associates (FAI) is excited to offer our “latest and greatest” addition to the flammability testing lab – the 20-L combustion vessel (Figure 1). This specially built spherical vessel is designed to safely handle standard and custom gas/vapor flammability tests with starting temperatures from ambient up to 350°C and pressures from ambient up to 100 bar (1450 psi). Furthermore, the vessel is constructed of 321 stainless steel to ensure resistance to corrosive materials. The vessel is also fitted with a self-cooled gas stirrer to establish constant mixing when adding various components to achieve uniformity of the gases and/or vapors inside the chamber prior to ignition. Currently, the vessel is equipped to perform flammability limits (LFL & UFL) testing per ASTM E918, limiting oxygen concentration (LOC) testing per ASTM E2079, and explosion severity (Pmax & KG) testing per EN 15967. A few advantages and disadvantages that the spherical 20-L vessel has over our standard spherical 5-L vessel can be seen below.

Advantages

- Excellent for testing materials that require large quenching distance to ignite, such as halogenated compounds

- The testing vessel can be uniformly heated up to 350°C, as opposed to 300°C

- Reduction in the data impact of “ringing” effects from ignitions of energetic materials that have very high pressure rise rates (dP/dt)

- Ignition source can be an electrical spark igniter or fuse-wire igniter, as opposed to only a fuse-wire ignition source

Disadvantages

- Longer duration of testing campaigns due to slower vacuum/purge cycles in between trials at the larger volume

- Larger sample amounts required for testing given the larger volume

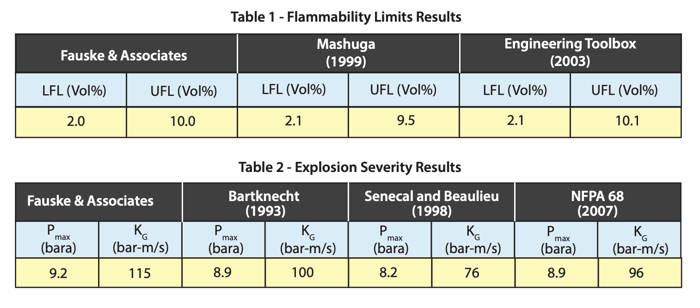

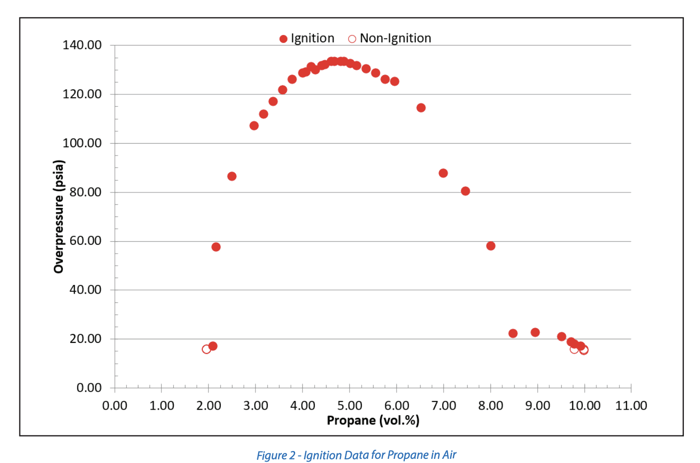

Verification tests were performed in the 20-L chamber across the flammable region of propane in air using methods referenced in ASTM E918 and EN 15967 to ensure the functionality of the apparatus. These results are presented graphically in Figure 2. The flammability limits and explosion test results are compared with reported literature values in Tables 1 and 2, respectively.

As seen in the tables, the deflagration results obtained for the propane-air mixtures are in good agreement with previously reported values in literature while the Pmax and deflagration index (KG) obtained are slightly higher (more conservative) than the literature data. It is noted that the maximum overpressure and the deflagration index are affected by numerous experimental conditions which include temperature, moisture content and purity of the gases, and the ignition source used. Additionally, the deflagration index increases with vessel volume (EN 15967, 2011). Thus, it is likely the slight variation between the FAI results and the reported literature values (which also show variability between sources) is attributable to the experimental procedure, conditions used during the test, and the larger vessel volume used by FAI. All things considered we are very pleased with the performance of our new instrument. We look forward to using our expanded flammability testing capabilities in support of your process safety needs. For more information, please contact us at flammability@fauske.com.

REFERENCES

Engineering ToolBox, (2003). Gases - Explosion and Flammability Concentration Limits. [online] Available at: https://www.engineeringtoolbox.com/explosive-concentration-limits-d_423.html

EN 15967:2011-10, Determination of Maximum Explosion Pressure and the Maximum Rate of Pressure Rise of Gases and Vapours; Deutsche Fassung EN_15967:2011.

Mashuga, C. V. (1999). Determination of the Combustion Behavior for Pure Components and Mixtures using a 20-Liter Sphere. Michigan Technological University. Ann Arbor: UMI Company.

NFPA 68. (2007). Standard on Explosion Protection by Deflagration Venting: National Fire Protection Association.

Senecal, Joseph A., and Patricia A. Beaulieu. “KG: New Data and Analysis.” Process Safety Progress, vol. 17, no. 1, 1998, pp. 9–15.