Oxidizing Solids (Combustible Dust Hazard) continued on page 4 Oxidizing substances increase the combustion capabilities of nearby materials, usually by acting as a more reactive oxygen source than the ambient oxygen in the air. The oxidative strength of an oxidizer can vary wildly based on its composition and, especially for solids, factors like particle size and moisture content. As such, classifying oxidizers based on their relative oxidative strength is important for determining the proper safety measures when storing, shipping, and handling oxidizers.

The UN Model Regulations assign Division 5.1 for oxidizing solids, liquids, and gases. Solid oxidizers can be classified using the UN Test 0.3: Gravimetric test for oxidizing solids from the UN Manual of Tests and Criteria. This test compares the oxidative strength of the test material with a standard oxidizer and based on the test results, classifies the test material as an oxidizing substance or not. If the test material meets the criteria for an oxidizing substance, it is then further classified into one of three Packing Groups depending on severity. This article provides an overview of how the test is performed and provides example photos and results.

UN Test 0.3: Gravimetric Test for Oxidizing Solids

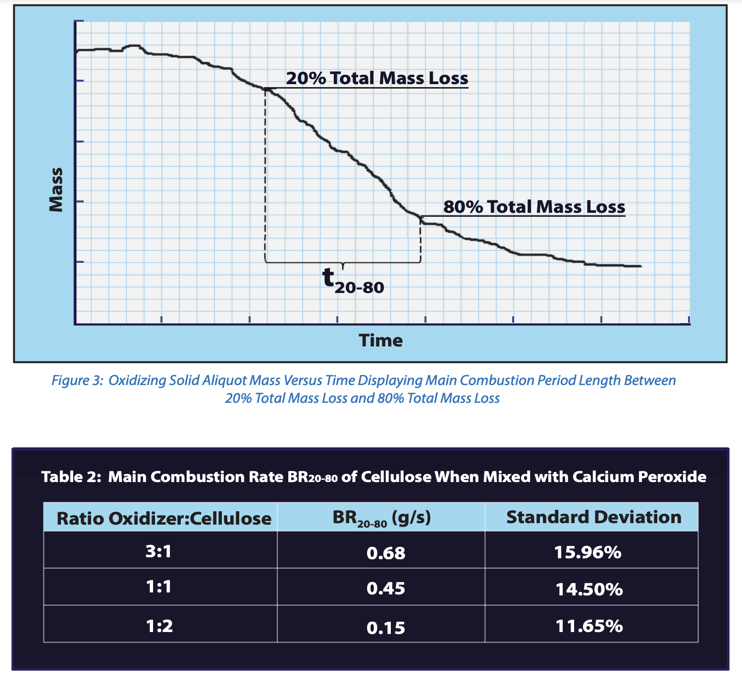

The test setup, Figure 1, primarily involves a digital weigh scale connected to a nearby computer, an insulative test plate on the scale, and a wire for igniting the sample. A solid base plate under the scale protects the measurements from vibration. A positioning plate with wide holes is used in conjunction with thin rods projecting up from the base plate to consistently position the test plate on the scale. This positioning plate can also provide further insulation. The setup is protected by a small wind shield to prevent air currents from affecting the data.

The test setup, Figure 1, primarily involves a digital weigh scale connected to a nearby computer, an insulative test plate on the scale, and a wire for igniting the sample. A solid base plate under the scale protects the measurements from vibration. A positioning plate with wide holes is used in conjunction with thin rods projecting up from the base plate to consistently position the test plate on the scale. This positioning plate can also provide further insulation. The setup is protected by a small wind shield to prevent air currents from affecting the data.

To perform the test, the test sample is mixed with cellulose into 30 g aliquots at ratios of 1:1 and 4:1. A cone of aliquot is placed on the scale and ignited. As the aliquot burns, the scale records weight measurements over time. Once the mass loss rate drops below 1 gram/minute, the reaction is considered complete. Five trials are performed for each ratio.

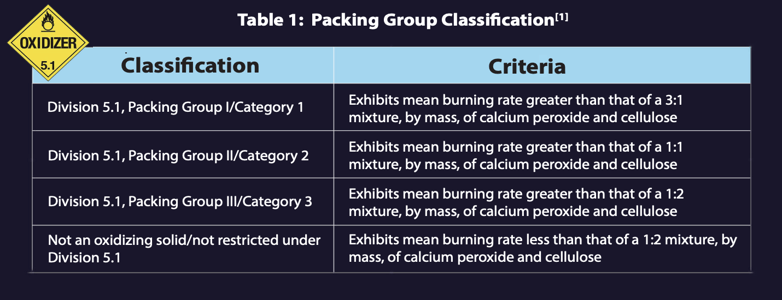

The burning rate during the main combustion period, or BR20-80, is determined by taking 60% of the total cellulose mass in the aliquot and dividing by the time elapsed between 20% total mass loss and 80% total mass loss. The sample’s higher mean BR20-80 between the two tested ratios is used for categorization.

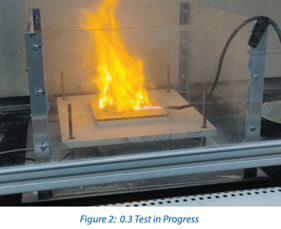

The standard material for the test, calcium peroxide, is tested at ratios of 3:1, 1:1, and 1:2. The standard’s BR20-80s are used in the Division 5.1 and Packing Group classifications, which are outlined in Table 1.

Standard Calcium Peroxide Test 0.3 Example Trial Data and Results

The standard reference material described in UN Manual of Tests & Criteria is calcium peroxide. Figure 2 and Figure 3 show example results for one trial. Typically, 5 trials are performed per ratio.

Table 2 lists example results after all trials are complete. Standard deviations greater than 20% warrant error analysis and repeating the test to obtain more consistent results. Similarly, if a linear regression of the data within the t20-80 region yields an R2 value less than 0.90, it is advised that the trial be repeated.

Conclusion

Strong oxidizers greatly increase both the risk and the consequences of accidental fires during handling or storage. Understanding the proper shipping, handling, and storage procedures of an oxidizer requires an understanding of its oxidative strength. As such, categorizing oxidizers relative to a standard oxidizer provides crucial insight when assessing hazards in an associated process line. The 0.3 Gravimetric test for oxidizing solids allows for categorization of oxidizers using precise numerical measurements.

References

- [1] UN Manual of Tests and Criteria, Seventh Revised Edition (2019)