By Ursula Malczewski, Chemical Engineer, Risk Management, Fauske & Associates, LLC

In the fall of 2015, the National Fire Protection Association (NFPA) issued its first edition of NFPA 652: Standard on the Fundamentals of Combustible Dust, 2016 Edition. This new standard establishes the relationship and hierarchy between it and the industry specific standards (NFPA: 61, 484, 654, 655, 664) to ensure that fundamental requirements are consistently addressed across industries, processes and dust types. Below is a summary of how this standard affects you and your combustible particulate solids handling process.

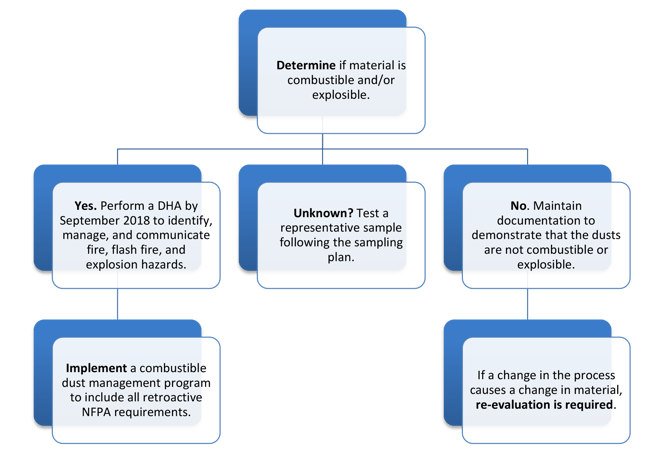

Figure 1 - NFPA 652 Immediate Action Items

Your Responsibility

The owner/operator of a facility (you) with potentially combustible dusts is responsible for determining whether the materials are combustible or explosible. The absence of previous incidents cannot be used as the basis for deeming a particulate to not be combustible or explosible.

Any facility handling/generating dusts, powders, or materials that during processing are found to break apart into smaller pieces may in fact be dealing with a combustible particulate solid. This means that these facilities are required to determine if the material they handle is combustible or explosible. If so, the owner/operator (you) is responsible for characterizing the properties of the material as required to support the Dust Hazard Analysis (DHA). The DHA must then be completed within 3 years of the effective date of this standard (by September 2018).

Determination of Combustibility and Explosibility

The determination of combustibility and explosibility is based on:

(1) Historical facility data or published data that are deemed to be representative of current materials and process conditions; or

(2) Analysis of representative samples by testing.

It should be noted that a material can be combustible but not explosible, explosible but not combustible or both combustible and explosible. If the combustibility or explosibility is not known, determination of these properties must be determined by standard-specified tests. These tests must be performed on representative samples based on the sampling plan.

The location of sampling is critical to obtaining meaningful results. The finest particles in your process represent the highest hazard. These tend to collect in dust collectors and on elevated surfaces.

It is permitted to assume a dust is combustible and/or explosible and proceed with all protections mandated by the standard, negating the need to perform the determination. However, further testing will need to be conducted in either case in order to determine the necessary safety protection systems specific to the material and process. The findings (test results, historical data, and published data) shall be documented and, when requested, provided to the authority having jurisdiction (AHJ). Your AHJ may include OSHA, your insurance company, or your fire marshal.

Next Steps

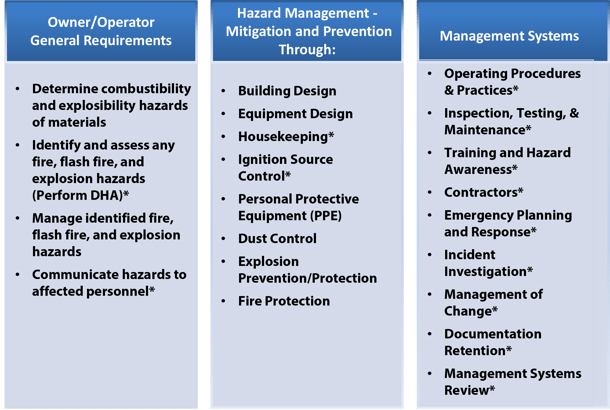

Where dusts are determined to be combustible or explosible, controls to address the hazards associated with the dusts must be identified and implemented. The process will need to have a technical safety basis including equipment protection, controls, and safeguards identified in order to ensure that future fires and explosions can be prevented or mitigated. The owner/ operator of the facility (you) is responsible for identifying and assessing any fire, flash fire, and explosion hazards (performing a DHA), managing the

identified fire, flash fire, and explosion hazards, and communicating the hazards to affected personnel in accordance to the standard.

If explosible dust is present in your facility or handled in your process, several management systems need to be in place to manage this hazard. Implementing a combustible dust management program will include all of the retroactive requirements of NFPA 652 (Figure 2).

*Retroactive Requirements

*Retroactive Requirements

Figure 2 - NFPA 652 Requirements

If materials are determined to not be combustible or explosible, the owner/operator (you) is required to maintain documentation to demonstrate that the dusts are not combustible or explosible. Your work here is done – for now…

In both cases, if/when there is a change in your process that causes a change in your material (new raw material or product, change

in supplier, etc.) or its environment (temperature, residence time, exposure to gases or other materials, etc.), new testing may be necessary to determine if the combustibility and explosivity properties have changed and what, if any, precautions are now required.

For additional information on determination testing, onsite dust hazard analysis (DHA), and implementing a combustible dust management program or to find out more about how this and other NFPA standards apply to your process, contact Theis@fauske.com, 630-887-5211

References

1. NFPA 652 (2016) Standard on the Fundamentals of Combustible Dust, 2016 Edition. NFPA, Quincy, MA.