Innovative Nuclear Waste Hydrogen Removal Design For Self-Shielded Containers

by Martin G. Plys, ScD, and James P. Burelbach, PhD, Fauske & Associates

A practical solution to the problem of hydrogen removal that permits the storage of spent metallic fuel and zeolytes in a shielded container with commercially available filters...

Introduction

In partnership, Sellafield Ltd, Westinghouse Electric UK, and Fauske & Associates, considered design parameters and options for interim self-shielded storage of waste that contains metallic spent nuclear fuel pieces or zeolytes. It was found that this type of waste generates significant hydrogen as a product of chemical reactions and from radiolysis of water. Filtered vents need to be implemented on waste containers that hold this waste to prevent unwanted hydrogen accumulation. In order to attach the filters to the shielded containers, bore-holes must be drilled through the shielding to allow the hydrogen to reach the filters. The specific geometry of the bore-holes must be designed carefully to preserve shielding while minimizing resistance to hydrogen removal.

|

| Filters |

Filters for H2 Removal

The rate of hydrogen removal through a filter varies with filter size and materials.

The key filter specification provided by the manufacturer is known as the filter coefficient, expressed in units of moles hydrogen per second per mole fraction difference across the filter.

Typical values range from 10-5 over 2x10-4 moles/s/mole fraction.

The filter design for a given application Is chosen based on the hydrogen generation rate and the target maximum hydrogen concentration:either the lower flammability limit (LFL) (4% hydrogen in air) or the stricter criterion of 25% of the LFL (1%hydrogen in alr).

Experimental Setup

|

| Lid & Pipe Configurations |

Small and large scale testing was performed. Initially the tests were performed transiently by establishing an initial hydrogen concentration of about 4% and then allowing the concentration to decay as hydrogen was vented out the filter and was replaced by air coming in the filter. Later tests incorporated a steady-state methodology in which a constant hydrogen inflow was established.

|

| Configuration D: Double bore-hole arrangement with single filter |

Innovative Solution for Hydrogen Removal

|

| Shielded Containers |

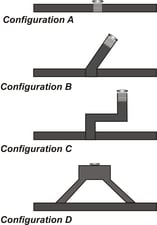

The key to hydrogen removal from a shielded container is to reduce the flow resistance such that the filter is the main resistance. Consider an arrangement to promote hydrogen circulation to the filter via a pair of bore-holes in the shielded container lid as shown in Configuration D. The hydrogen concentration in a plenum immediately on the inside of the filter is lower than the hydrogen concentration in the container, so the density difference induces circulation.

Gas from the container flows up one of the bore-holes into the plenum beneath the filter and then down the other bore-hole, returning to the container. In Configuration D, the bore-holes are indicated on an angle for shielding purposes, and in practice a double-angle design would be used to prevent a direct straight line path through the container lid.

Modeling demonstrated that Configuration D would be nearly as effective as Configuration A, providing a solution to hydrogen removal from a package with thick shielding. In contrast, commonly employed Configurations B and C would have sufficiently low efficiency compared to Configuration A that these designs are impractical.

Results

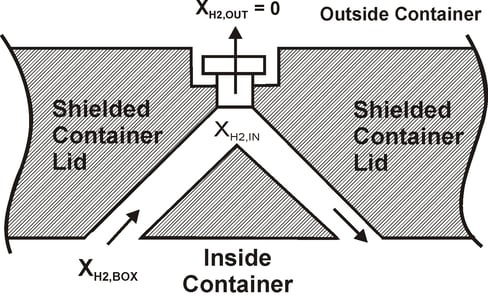

The expected performance of the dual-bore design was confirmed through experiments for different filter types and variation in hydrogen concentration. An example comparison of a priori expectation versus actual system data is shown below.

The efficiency of the double bore system can be in the range of 80% to 90%, depending upon the geometry and the hydrogen concentration in the container. Thus, the number of filters required for a given application may be, for practical purposes, unaffected by the extra resistance offered by the shielding, and at worst it is only weakly affected.

|

| Experimental Results and Model Predictions |

Conclusions

The dual-bore Configuration D achieves an effective filter performance which is comparable to that for a filter alone and is superior to any single bore design. This innovation minimizes the number of vents required for a given inventory of metallic fuel bearing waste.

Steady-state testing with a well-defined hydrogen source rate together with the corresponding steady-state hydrogen concentration results in an effective filter efficiency which is reproducible and independent of hydrogen concentration.

Large scale tests indicate that the integral performance of multiple filter assemblies is simply given by the product of the number of filter assemblies and the performance of an individual assembly as measured in small scale tests.

-3.png?width=389&name=Chemical%20Technology%20Dec%202014_pg22-24%20(2)-3.png) |

| The First Generation Magnox Storage Pond at Sellafield |

Implications

In partnership, Sellafield Ltd, Westinghouse Electric UK, and Fauske & Associates, have conceived, modeled and experimentally verified an innovative solution to the problem of hydrogen removal from shielded containers with significant hydrogen generation rates. This solution to the problem of hydrogen removal permits passive storage of spent metallic nuclear fuel and zeolytes in a shielded container that is vented by a practical number of commercially available filters.

For more information regarding nuclear waste technology, decommissioning, modeling and plant services in addition to chemical and industrial process safety and testing, please contact us.