Nuclear Waste Technology Analytical Services - What to Look For

Operational nuclear facilities and legacy reprocessing sites have unique engineering challenges to address. Safe and efficient nuclear waste processing can require innovative technical solutions, without which, a basic engineering task can appear very complicated.

Comprehensive analytical solutions address all project aspects from fundamental process and safety evaluations to efficiency and technical basis justification.

Areas of Expertise Needed

- Aerosol Physics

- Chemical Reaction Rates

- Criticality

- Emergency Response

- Engineered Basis

- Explosions

- FATE Software

- Fire Modeling

- Flammability & Combustion

- Full Service (Analytical, Field Service & Laboratory)

- Integrated Process Evaluation

- Hydrogen Generation

- Radioactive Gas Transport

- Radiolysis

- Source Terms

- Thermal-Hydraulics

The most experienced engineering lab and testing services will have performed previous projects such as:

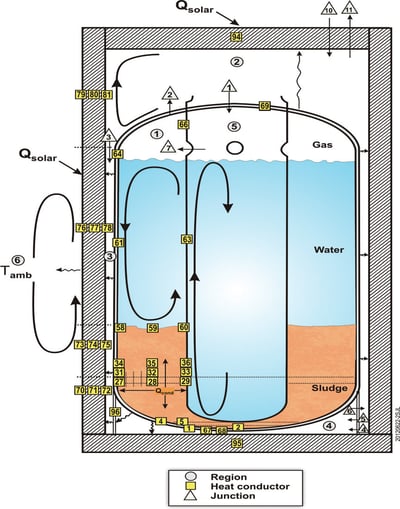

Sludge Transport and Storage Container

Developing and performing heat generation and heat transfer of a storage container containing radioactive sludge. Evaluations included the potential for criticality, hydrogen generation rates and proper vent sizing requirements. In addition, a safety evaluation performed to assess the developed new technology.

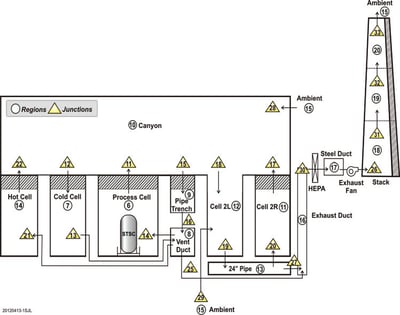

Interim Fuel Storage Integrated Evaluation

Fully integrated engineering evaluation of an interim storage facility. Evaluations include hydrogen generation, gaseous transport along with postulated off-site releases.

Hydrogen Accumulation - Post Fukushima

Playing a key role in the evaluation of the Fukushima accident including analyses of the accumulation of hydrogen in the reactor buildings.

Interim storage

.jpg?width=300&name=Hydrogen%20accumulation%20risk%20in%20reactor%20buildings%20(post%20Fukushima).jpg)

Hydrogen accumulation risk in reactor buildings (post Fukushima)

"By coupling analytical, field service and laboratory capabilities together, top engineering firms provide full service solutions," states Fauske & Associates, LLC (FAI) Nuclear Services Manager Jackie Shoulders. "With nearly 40 years of success servicing the nuclear and chemical industries, we have acquired broad expertise, welcome First Of A Kind (FOAK) projects and regularly think outside of the box."

Continues Shoulders: "The following is an abbreviated list of customers we have been fortunate to service:

- Hanford Site

- Savannah River Site

- UK’s Sellafield Site

- Sandia National Lab

- Numerous operating & closed commercial nuclear power generation plants".

While considering skill set and experience in nuclear and industrial waste tech analytical services, top engineering firms should provide a formula of proven longevity + comprehensive talent.