Recommendations on the Maximum Operating Pressure of ARC Test Cells

At Fauske & Associates, LLC (FAI), we are commonly asked about the burst pressures of the Accelerating Rate Calorimeter (ARC) test cells that we offer. The ARC is a high thermal inertia adiabatic calorimeter that is used to obtain runaway chemical reaction data and thermal stability properties. As a runaway reaction occurs in this apparatus, the pressure within the test cell naturally rises whether it be due to vapor pressure effects, the generation of non-condensable gas, or both. The pressure generated by the runaway reaction must be contained by the test cell. As a result of this requirement, the mass of the test cell is relatively large compared to the mass of test sample used. This means that as a runaway reaction progresses, heat from the reaction is absorbed by the test cell and the data are not directly applicable to the process scale.

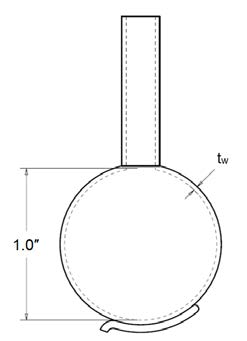

The standard ARC test cell is approximately 10 ml in volume and is typically constructed of stainless steel, Hastelloy C, titanium, or tantalum. This size of test cell has an internal diameter of 1.0 inches. The wall thicknesses of test cells can be 0.020, 0.025, or 0.035 inches. A diagram of a test cell is provided in Figure 1.

|

| Figure 1 Standard 10 ml ARC Test Cell |

The reasoning behind the desire to know the burst pressure is so that as much sample material can be added to the test cell as possible without causing a rupture during the test. This reduces the thermal inertia (or essentially, the amount of heat absorbed by the test cell) and ensures lower energy exothermic activity isn’t masked. However, regardless of how much sample is loaded to a test cell, the resulting thermal inertia will never be representative of the process scale (1.05 - 1.10).

The ARC isn’t, and never was, intended to be a low thermal inertia calorimeter. The data from this apparatus will require correction for the thermal inertia. If low thermal inertia data are desired, a calorimeter intended for operation at low thermal inertias Vent Sizing Package 2 (VSP2TM) or Advanced Reactive System Screening Tool (ARSSTTM) should be used.

Furthermore, this issue isn’t as simple as telling an ARC user the burst pressure of a particular test cell. When designing a test, one must balance a number of variables to ensure optimal results: the sample mass, the maximum temperature that could be achieved during the test, the maximum pressure that could be achieved during the test, the maximum self-heat rate under which adiabatic conditions are maintained, and material compatibility between the test cell and sample.

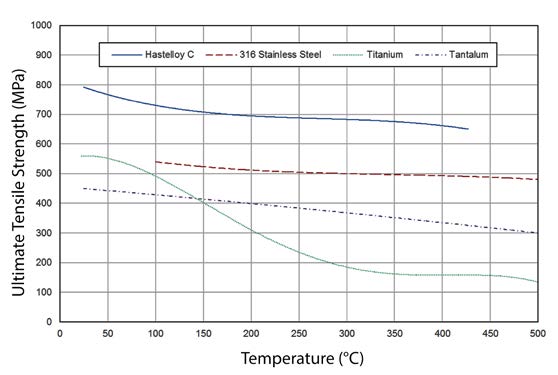

In order to address the original question regarding test cell burst pressure, we’ll focus on how the ultimate tensile strength of a given test cell material and the wall thickness are related to the peak temperature and peak pressure resulting during a test. The ultimate tensile strength decreases with increasing temperature. Figure 2 illustrates the effect of temperature on the ultimate tensile strengths of common test cell materials. Based on those tensile strengths, the theoretical burst pressures can be calculated for spheres with the specified dimensions provided in Table 1 using Equation 1 below.

σt = ![]()

where

σt = ultimate tensile strength (Pa)

tw = wall thickness of spherical portion of test cell (m)

r = inner radius of test cell (m)

P = internal gauge pressure (Pa)

|

| Figure 2 Ultimate Tensile Strength as a Function of Temperature for ARC Test Cell Materials |

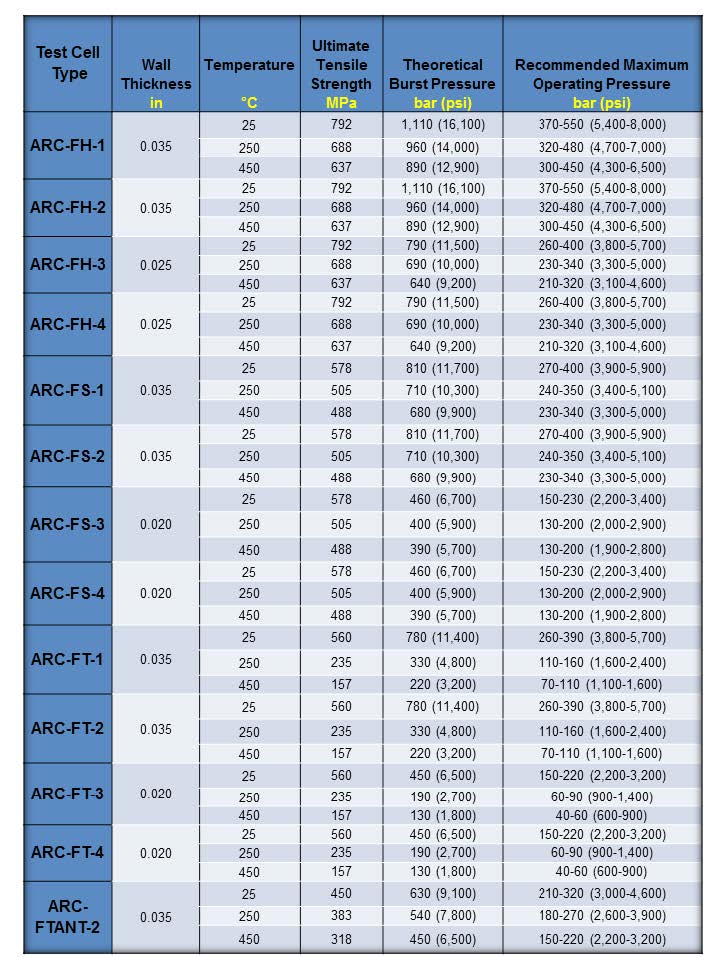

These are, of course, “ideal” calculations for a sphere that don’t account for the actual geometry of the test cell, nor imperfections that invariably occur during the manufacturing process. For example, the presence of a weld seam and the inhomogeneous microstructures within the welded metal leads to higher corrosion rates when compared to wrought products. Types of factors such as this need to be taken into account. For this reason, the theoretical burst pressures should not be used for test design - a safety factor of 2 to 3 should be used. Table 1 summarizes the theoretical burst pressures and our recommended maximum operating pressures for the various ARC test cells we offer.

| Table 1 Theoretical Burst Pressure and Recommended Maximum Operating Pressure as a Function of Maximum Test Temperature for Standard ARC Test Cells |

|

If you enjoyed learning about ARC and its purpose, check out our case study on low thermal inertia adiabatic calorimetry. In this case study, FAI performs tests to determine what is the self accelerating decomposition temperature of a 50 kg package of azodicarbonamide. Download the case study now to to learn more about AKTS software, self accelerating decomposition temperature, the United States SADT test, and much more.

References

Haynes International, “Hastelloy C-276 Alloy Tensile Strength and Elongation.” Retrieved September 5, 2018

from http://haynesintl.com/alloys/alloy-portfolio_/Corrosion-resistant-Alloys/HASTELLOY -C-276-Alloy/tensile-strength-and-elongation

North American Stainless, “Flat Product Stainless Steel Grade Sheet 316 - 316L.” Retrieved September 5, 2018

from https://www.northameric anstainless.com/wp-content/uploads/2010/10/Grade-316-316L.pdf

Kobelco, Kobe Steel Group, “Highest Specific Strength of Existing Metallic Materials - Characteristic s.” Retrieved September 5, 2018

from http://www.kobelco.co.jp/english/titan/files/details.pdf

Pick PM , Metal Powder Industries Federation, “What Are Refractory Metals?” Retrieved September 24, 2018

from https://www.pick pm.com/wp-content/uploads/2016/08/What-Are-Refractory-Metals.pdf

Davis, J.R., ASM Specialty Handbook - Heat-Resistant Materials - Part I. Introduction. ASM International.(1997). Retrieved September 5, 2018

from https://app.knovel.com/hotlink/pdf/id:kt00URR 0YB /asm-speci alty-handbook/part-i-introduction