Replacing Complex Two-Fluid Models With A Simple Model

Replacing Complex Two-Fluid Models With A Simple Model That Has No Adjustable Parameters and That is Agreeable With Experimental Data Including Both Non-Equilibrium and Equilibrium Flashing Flows

By: Hans K. Fauske, D. Sc., Regent Advisor, Fauske & Associates, LLC (FAI)

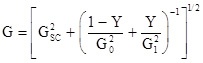

In contrast to the two-fluid models that require numerous assumptions and the corresponding closure equations, the Simple Model can be stated as:

(1)

(1)

where G (kg m-2 s-1) is the Non-Equilibrium or Equilibrium two-phase flow rate including the effects of subcooling (GSC), Y is the dimensionless independent variable ranging from 0 to 1 and G0 and G1 are the corresponding asymptotic flow rate limits. For all specified stagnation conditions (subcooled liquid, saturated liquid and liquid-vapor mixtures) and flow geometries (nozzle, short and long), the easy to estimate G values in the region between the known asymptotic limits with no arbitrary adjustable parameters are in remarkable agreement with available experimental data. The nozzle constant area length L is the key parameter and values (Y) leading to non-equilibrium and equilibrium flashing flows is provided by (Fauske, 1985, 2017).

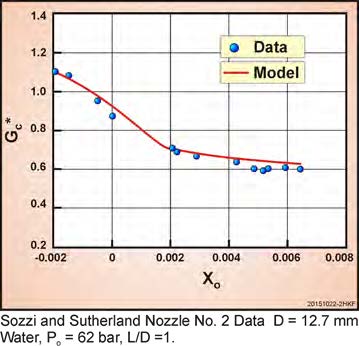

An example is illustrated below the agreement of the simple model is consistently good for all inlet quality (Xo) conditions, where Gc is the dimensionless mass flux, defined as G/√Poρo, and quoting Sozzi and Sutherland (1975), stagnation quality (Xo) in the vessel upstream of the nozzle is based on the density in the vessel and the stagnation pressure (Po):

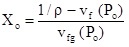

(2)

(2)

when the liquid is subcooled, vf >1/ρ and, consequently Eq. 2 results in Xo < 0 as a negative quality.

It should be noted that the short nozzle No. 2 (D = 12.7 mm and L/D = 1) non-equilibrium data by Sozzi and Sutherland (1975) have provided difficulties in predicting especially with two-fluid modelling which required empirical adjustment to fit the test results (Levy, 1993).

For more information or to discuss two-phase flow concerns, contact Kris Fauske at 630-887-5213, kfauske@fauske.com

References

Hans K. Fauske, 1983, "Flashing Flows Or: Some Practical Guidelines for Emergency Releases," Plant/Operations Progress, July, 1985.

Hans K. Fauske, 2017, "Further Clarification of Non-Equilibrium and Equilibrium Flashing Flows Through TOP Located Relief Valves (SRVs)," Process Safety News, Summer 2017, Volume 24, Number 3.

Solomon Levy, 1999, "Two-Phase Flow in Complex Systems," A Wiley Interscience Publication, 1999.

Sozzi, G. L. and Sutherland, W. A., 1975, "Critical Flow of Saturated and Subcooled Water at High Pressure," Report NEDO-13418, General Electric Company, San Jose, Ca (July).