By TJ Frawley, Flammability Projects Manager, Fauske & Associates

It is well known throughout the process safety industry that any fire, explosion, detonation, or form of combustion is the product of a combination of hazardous elements. Whether it is a leg of the flammability triangle or part of the pentagon of dust explosibility, the presence of an ignition source is always a threat, especially in high temperature environments.

This article focuses on temperature acting as the ignition source. At Fauske and Associates (FAI), we have multiple test methods to determine the temperature in which a material will auto-ignite. These methods are split into two categories, the auto-ignition of solids in the form of dust and the auto-ignition of vapors and gases. It may seem that these differences are fairly obvious, however, there is some overlap. For example, if you need a solid material tested but it has a low melting point, do you test for the explosive properties while in a solid state? Or ,do you test for the ignition temperature of the vapors given off as the material transitions into a liquid? Or, which test is best suited for a solid saturated in a liquid?

This article is here to help you answer these questions and others like it. Let us begin with the test methods that are focused around solids.

First, a Layer Ignition Temperature (LIT) test. This test determines the temperature at which a layer of dust will combust when placed on a hot surface. This may also be referred to as spontaneous combustion. As the temperature of hot surface increases, the likelihood of a material reaching its auto-ignition temperature also increases. The heat generated in the dust layer is greater than the amount of heat dissipated into the environment and eventually the temperature within the dust layer will run away to point the material ignites.

Continuing with solids auto-igniting, next we look at the Minimum Ignition Temperature (MIT) test. This may also be known as a BAM oven test. This test determines the temperature that a dust cloud will auto-ignite. Here, a dust is dispersed into an oven at a given temperature. The temperature is decreased until no ignition is observed. The test is then repeated over a range of concentrations.

The LIT and MIT tests are alluded to in NFPA 654, Standard for the Prevention of Fire and Dust Explosions from the Manufacturing, Processing, and Handling of Combustible Particulate Solids. Section 9.7, Hot Surfaces states:

“In areas where a dust explosion hazard or dust flash fire hazard exists, the temperature of external surfaces, such as compressors; steam, water, or process piping; ducts; and process equipment shall be maintained below 80 percent (in degrees Celsius) of the lower of the dust surface ignition temperature or the dust-cloud ignition temperature.”

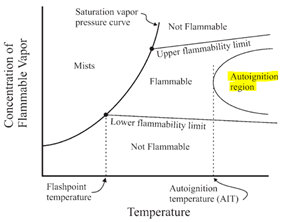

Now, we will begin the transition from testing solids to testing gases and vapors. We will determine the highlighted section of the accompanying graph.

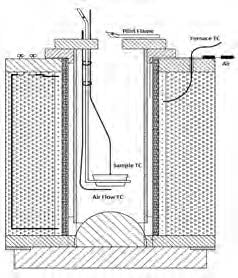

The next test is where we may see some overlap between testing solids and vapors. This is the Spontaneous Ignition Temperature (SIT) test. The SIT is best for solids with low melting points that may produce flammable vapors. These type of products include, but are not limited to plastics and rubbers. The SIT also applies to solids that may contain liquids or are saturated in liquids. In the illustration of the SIT apparatus, the solid sample would be placed within the sample cup and then lowered into the furnace/oven. Over a period of time, the sample will melt and produce vapors. Air is flowing up through the furnace to ensure there is a sufficient quantity of oxygen to propagate an ignition.

Last and certainly not least, especially from a safety perspective, is the Auto-Ignition Temperature (AIT) test. The AIT focuses on the autoignition of vapors and gases. Typically, but not in every case, the AIT will result in a lower ignition temperature due to the ease in which those particles are excited compared to the solid counterparts. It is also important to note that the ASTM standard for the AIT requires a more accurate testing range than the previously mentioned tests.

If you have a process that includes drying or curing a material in an oven, it is best to know the SIT and/or AIT of your material and operate below that temperature. Also, the SIT and AIT tests are especially applicable when adhering to NFPA 70, National Electrical Code. The following is an excerpt from that code, Article 500 – Hazardous (Classified) Locations, Classes I, II, and III, Divisions 1 and 2:

“Equipment shall be identified not only for the class of location but also for the explosive, combustible, or ignitible properties of the specific gas, vapor, dust, or fibers/flyings that will be present. In addition, Class I equipment shall not have any exposed surface that operates at a temperature in excess of the auto-ignition temperature of the specific gas or vapor. Class II equipment shall not have an external temperature higher than that specified in 500.8(D)(2). Class III equipment shall not exceed the maximum surface temperatures.”

“Equipment shall be identified not only for the class of location but also for the explosive, combustible, or ignitible properties of the specific gas, vapor, dust, or fibers/flyings that will be present. In addition, Class I equipment shall not have any exposed surface that operates at a temperature in excess of the auto-ignition temperature of the specific gas or vapor. Class II equipment shall not have an external temperature higher than that specified in 500.8(D)(2). Class III equipment shall not exceed the maximum surface temperatures.”

Auto-ignition temperature data, whether for solids or liquids, are essential to designing an inherently safe process. If you are interested in speaking with an expert, contact us by clicking the button below.