Thermal Hydraulic Analysis and RELAP5 In Nuclear Engineering

Thermal hydraulic analysis is currently one of the most searched terms related to nuclear engineering.

Per Wikipedia: "Thermal hydraulics (also called thermohydraulic) is the study of hydraulic flow in thermal fluids. A common example is steam generation in power plants and the associated energy transfer to mechanical motion and the change of states of the water while undergoing this process."

The Reactor Excursion and Leak Analysis Program (RELAP5) is a light water reactor transient analysis code developed for the United States Nuclear Regulatory Commission (US NRC) for simulation of a wide variety of hydraulic and thermal transients in both nuclear and nonnuclear systems involving mixtures of steam, water, non-condensable gases and solutes under single phase and two phase conditions.

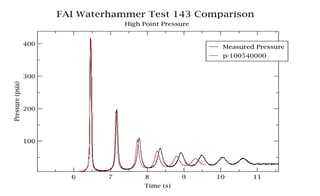

Fauske & Associates (FAI) engineers regularly utilize RELAP5 for thermal hydraulic safety analysis, including pre test  prediction and post test evaluation, as illustrated. Major experience includes extensive piping dynamic loads evaluations for AP1000® systems as well as system evaluations on operating nuclear plants in the U.S. and overseas.

prediction and post test evaluation, as illustrated. Major experience includes extensive piping dynamic loads evaluations for AP1000® systems as well as system evaluations on operating nuclear plants in the U.S. and overseas.

The RELAP5 code has received extensive validation and international participation in the development and testing of the code over the years. It is available for UNIX and PC platforms, with excellent post-processing software (APTPLOT). Its versatility enables the analyst to build models of system behaviors.

Features

- Fluid flow models

- Heat transfer characterization

- Non-condensable gas characterization

- Core kinetics

- Control systems

- Specialized component models

- Pipe element models

- Straightforward input from isometric drawings

- User control of wall friction/irreversible losses

- Flow regimes dynamically computed and include bubbly/slug/annular/stratified

- Pump models

- Homologous curve implementation

- Pump speed solution based on torque equations

- Vertical stratified flow models

- Valve Models

- Motor/check/servo models

- User controls on closing speed/time

- Check valve models are idealized - Boundary Conditions (BC) Models

- User specified flow and pressure BC - Specialized Junction Models

- Horizontal stratified vapor pull through models

For more information on RELAP Transient Analysis or Thermal Hydraulic Analysis, please visit www.fauske.com or contact us at info@fauske.com.