Weighing In On Balancing Knowledge And Action To Combat Dust Hazards

By Sara Peters, Customer Specialist, Fauske & Associates

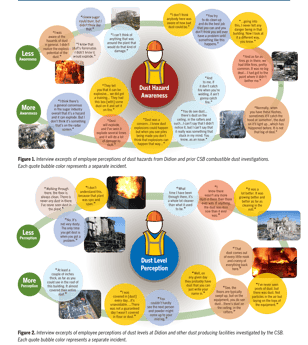

Recently, the US Chemical and Safety Board’s (CSB) revealed that their investigation into the May 2017 explosion at Didion Milling Company in Cambria Wisconsin exposed an industry wide issue that underscores multiple recent dust related incidents. It revealed what seems to be a wide spread disparity in understanding among workers in dust producing facilities regarding the hazards of combustible dust as well as when/how much dust in a facility is perceived to be a problem. In light of the understanding gap and the ongoing incidence of such tragic events, the CSB issued a call to action to explore this further.

Recently, the US Chemical and Safety Board’s (CSB) revealed that their investigation into the May 2017 explosion at Didion Milling Company in Cambria Wisconsin exposed an industry wide issue that underscores multiple recent dust related incidents. It revealed what seems to be a wide spread disparity in understanding among workers in dust producing facilities regarding the hazards of combustible dust as well as when/how much dust in a facility is perceived to be a problem. In light of the understanding gap and the ongoing incidence of such tragic events, the CSB issued a call to action to explore this further.

This call to action asks those impacted by dust including companies, workers, regulators, safety experts, etc. to answer some basic questions addressing matters related to how much dust respondents consider too much/unsafe. Are dust hazards effectively communicated across organizations? Are workers provided adequate guidance for prioritizing competing/conflicting standards regarding combustible dust control? How effective is communication regarding the hazards of combustible dust? All of this is information important to the evaluation of a facility’s safety procedures, but one key area that seems to have been overlooked for consideration is how risk factors into the equation.

Dr. Ashok Dastidar, Vice President, Dust & Flammability Testing and Consulting Services states, “The questions that the CSB are asking offer insight into the misunderstandings and knowledge gaps regarding the dangers combustible dust poses. It’s important to remember, however, that a hazard is inherent to a material, but the risk related to that material has to do with the manner and environment in which it is used. An effective safety program needs to incorporate information addressing both.”

Dr. Dastidar reiterates the benefit of dust hazard analyses as required by NFPA 652 as an effective means to evaluate risks in a facility stating, “Understanding how we can create a stronger awareness regarding the hazards of dust will enhance our ability to educate those affected by it. But, following the proper steps to characterize dust and addressing the unique variables creating risk in each individual situation through a dust hazard analysis (DHA) should still be a first step in developing a process safety plan.”

The takeaway here should be that mitigating the possibility of a combustible dust event requires an effective mix of action combined with education and communication. This call to action is a worthy conversation starter but can only impact change if the lessons are used to implement a more mindful approach to combustible dust control.

Want to know more about how to handle the combustible dust hazards and risks? Download our Dust Hazard Analysis Brochure today and see the benefits of our Dust Hazard Analysis course!