Process Hazards Analysis, Code Compliance and Procedure Development

Fauske & Associates can provide consulting services for processes related to risk reduction when handling chemicals, liquids and dust reactive hazards within a manufacturing facility. Consulting options are customized to meet your needs by providing a safety review on-site, desktop support for proposed building designs or any combination to meet your safety goals. The following are focus areas for safety audits that can be considered.

Dust Hazards Analysis (DHA) NFPA 652

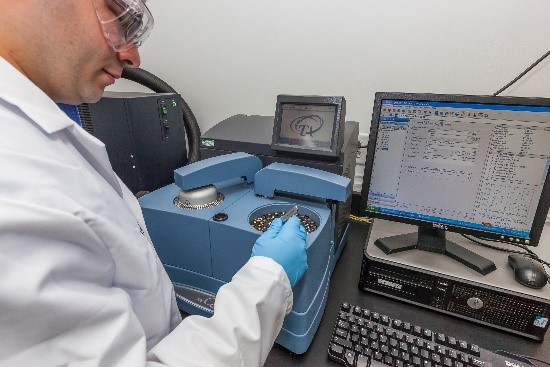

NFPA 652 requires a Dust Hazards Analysis (DHA) when your facility has dust or powders within the process that are explosible and/or combustible. The first step of the DHA is to determine if your facility has either one or both of those reactive materials by running combustible dust testing on a representative sample for your location.

Our process safety professionals have served clients in a variety of industries including metal processing, wood/paper products, agriculture, food products, textiles, plastics, pharmaceuticals and many others.

FAI can provide the following services:

- Incident investigation for dust explosions and fires

- Evaluate compliance with relevant national,

local and industry standards - Electrical hazards – e.g. grounding and bonding issues

- Recommendations for explosion hazard risk reduction

- Point out dust sampling areas to consider for dust explosibility testing

- Brief Training provided to personnel while on-site available upon request during site visit

FAI’s combustible dust experts can visit your facility to conduct the DHA, which is a hazard identification exercise that delivers recommendations to become compliant with applicable NFPA Standards. The evaluation is developed by reviewing dust management programs, handling practices, equipment, fire/explosion suppression systems, warning devices and onsite extinguishing capabilities. Possibilities for fugitive dust control will be identified, where appropriate.

NFPA and OSHA NEP Combustible Dust Compliance

- Preparation for an OSHA Combustible Dust NEP inspection, including appropriate response’s to inspector’s questions

- Perform Dust Hazards Analysis (PHA) for compliance with NFPA

- Documentation review for NFPA and OSHA Combustible Dust NEP requirement

- Testing to meet all NFPA and OSHA Combustible Dust NEP requirements

- Flammability Testing and on-site consulting services where flammable vapors are present

- Conduct employee training to comply with OSHA Combustible Dust NEP requirements, customized on-site training is also available

NFPA and OSHA NEP Combustible Dust Compliance

- Preparation for an OSHA Combustible Dust NEP inspection, including appropriate response’s to inspector’s questions

- Perform Dust Hazards Analysis (PHA) for compliance with NFPA

- Documentation review for NFPA and OSHA Combustible Dust NEP requirement

- Testing to meet all NFPA and OSHA Combustible Dust NEP requirements

- Flammability Testing and on-site consulting services where flammable vapors are present

- Conduct employee training to comply with OSHA Combustible Dust NEP requirements, customized on-site training is also available

Process Hazards Analysis (PHA)

A Process Hazards Analysis (PHA) is required for OSHA PSM or EPA RMP covered chemical facilities. The PHA is a rigorous and systematic approach to identifying, evaluating and controlling the hazards of processes involving highly hazardous chemicals. Consequences addressed can include employee safety, environmental impact, public safety, extent of equipment/facility damage and/or effects on public image.

Safeguards currently in place are accounted for, and where risk is unmitigated/deemed unacceptable, recommendations for follow-up actions are provided. A management review is later conducted to determine what changes will be made. The end goal of performing a PHA is not to label a process as "safe", but to detect unprotected situations and trigger the necessary safety improvements to reduce or minimize risk.

PRA - Probabilistic Risk Analysis (PRA)

The Probabilistic Risk Analysis (PRA) is commonly used in the Nuclear, Power, Airline, Transportation and Urban Planning industries. We can support the full-scale PRA or customize a PRA-Light version for customers trying to keep within a budget. Reach out to us to find out more about how we can support your process safety support.