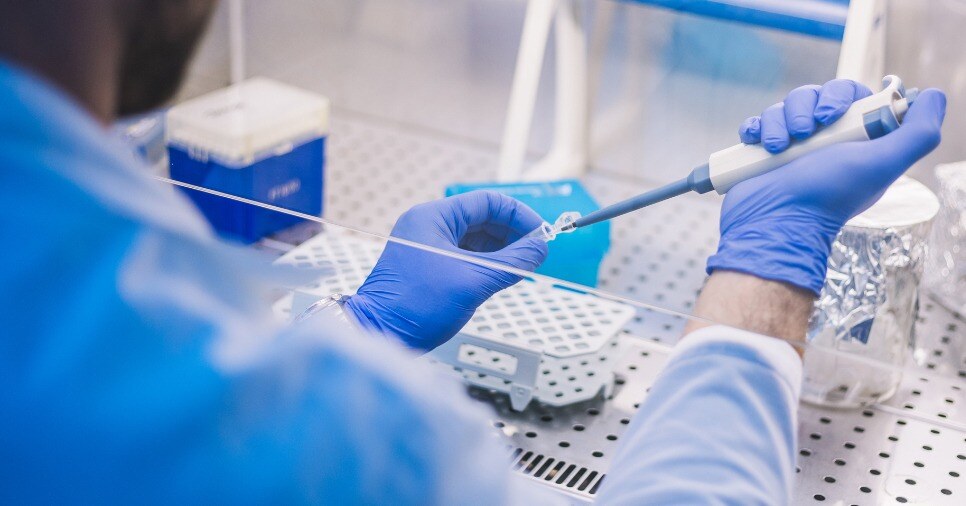

Our Experts Provide State of the Art Laboratory Testing Services

Chemical & Industrial Process Safety Services

Adiabatic Calorimetry & Relief Vent Sizing

Adiabatic calorimeter testing provides data for relief system design, safe scale-up of chemical processes, and changes to process recipes.

Combustible Dust Hazards Analysis and Testing

Adiabatic calorimeter testing provides data for relief system design, safe scale-up of chemical processes, and changes to process recipes.

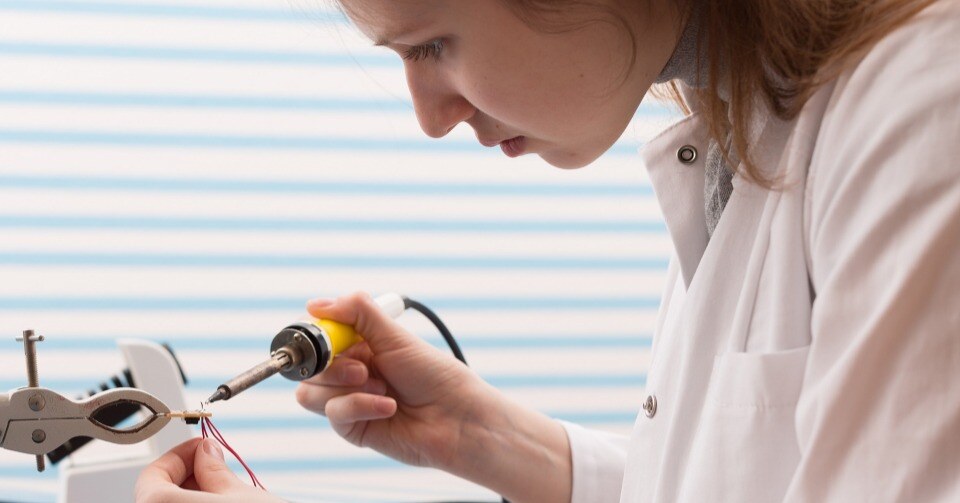

Failure Analysis

We provide a broad range of failure analysis services for unirradiated and irradiated components.

Reaction Calorimetry

A Section Heading Title

One of the keys to safely scaling up a chemical process is managing the energy or heat flux that the intended chemical reaction produces, especially when that chemical transformation is exothermic in nature.

On-Site Process Safety and Risk Management

In response to continued rapid growth in safety needs for the chemical and nuclear industries, Fauske & Associates (FAI) offers a complete range of Risk Management Services.

Thermal Stability

Often material safety data sheets refer to the thermal stability as an intrinsic property of a substance or mixture. In fact, this is an oversimplification of a concept that must be defined in a more comprehensive way.

UN-DOT Testing

Fauske and Associates (FAI) has extensive experience in characterizing the explosive or flammable nature of solids, liquids, vapors and gases. With this expertise, we are proud to offer a suite of UN/DOT testing of potentially dangerous goods.

Maintenance Optimization Modeling

For those seeking an optimal balance between

operability and cost, our Maintenance Optimization Modeling provides a simple but comprehensive solution that is based on probabilistic and statistical analysis of your most important plant assets.

We Have You Covered

Fauske & Associates proudly employs process safety professionals and industrial plant safety from around the world, speaking more than 17 languages at our laboratory headquarters in Burr Ridge, alone. We travel often and we also employ representatives worldwide for chemical & industrial testing services.

Published white papers, lectures, seminars and webinars are a vital and constant part of our outreach to customers, universities, industries, plants and government. As leaders in the world of process safety for both the nuclear and chemical/industrial sectors, we take very seriously our ability to educate and share about chemical and industrial testing services. Be sure to look for related materials on each topic page you visit.

Our Chemical Testing Services

On-site assessments, Risk Management Services, Calculations, DIERS Methodology, Relief System Design, Chemical and Industrial Testing Services, Industrial Plant Safety and Safety Program Reviews are just some of the safety-related services offered by FAI