Equipment Qualification (EQ) Testing

Fauske & Associates provides critical support to nuclear equipment manufacturers and suppliers, OEMs and utilities with a range of services and testing designed to qualify equipment, parts and components for many applications. These include both mild and harsh nuclear and chemical environments to meet NRC guidelines and industry and plant-specific requirements. Our testing capabilities are also applicable to non-nuclear equipment.

Equipment Qualification Services

Testing Services

Design Basis Accident Testing

- Our state-of-the-art stainless steel Loss of Coolant Accident (LOCA) chamber and test facility can easily achieve the required temperature and pressure transients representative of harsh environments for all existing and new Generation III+ reactors. In addition to our LOCA chamber, our High Energy Line Break (HELB) test facility is available to qualify components for mild environments

Aging Services, EMC, EMI And Seismic Qualification

- We provide all testing and aging services to qualify your components including thermal and irradiation aging, EMC/EMI and seismic qualification.

Activation Energy Determination, Material Testing, Forensics and Identification

- Utilizing our extensive database of activation energies, we can provide referenced activation energy values for numerous components. We also have a complete laboratory that can perform actual activation energy tests using one of our test instruments including micro-watt calorimetry, DSC, TGA and others.

Harsh Environment Testing

- We have the capability to perform tests which expose equipment to chemical spray.

Our material testing laboratory is also equipped with instruments including a Fourier Transform Infrared (FTIR) Spectrometer utilized for various applications related to Material Forensics and Identification testing to identify what the component material is and to perform forensics. Additionally, aged materials can be evaluated to determine the response of the material as a result of the environment conditions.

Material Performance testing is delivered using our INSTRON material property test rig which is able to perform industry standard tests including tensile strength and strain to determine mechanical properties of components.

Other Services

Consulting Services

- Along with our testing services, we also provide engineering consulting services to assist with your qualification process. Our engineering services include determining solutions for components that fail or do not perform well during testing, and the ability to perform analytical calculations (thermal lag, seismic, radiation shielding, etc.) to properly account for environmental conditions at the equipment location.

Establish Actual Plant Normal Service Conditions

- Using around the clock monitoring instrumentation, our engineers can establish actual normal service plant conditions (temperature, radiation, etc.). Actual plant conditions may be less than calculated design conditions offering improvement with the environmental conditions.

Establish Representative Temperature Profiles

- If upper boundary maximum temperature conditions within a given room are the basis for your equipment environmental qualification, having representative time dependent temperature profiles could remove these conservatisms and margins. FAI can provide these time dependent temperature profiles using appropriate calculations and/or software tools.

Evaluation of Failure Criteria

- An evaluation by our team can determine the particular types of accident conditions the piece of equipment being tested will need to respond to. For instance, if the specified equipment is required to operate following a High Energy Line Break (HELB), but not a Loss Of Coolant Accident (LOCA), the conditions corresponding to the HELB will be used to evaluate the corresponding environmental conditions, rather than defaulting to the generic “worst” case conditions.

Failure Modes and Effect Analysis (FMEA)

- Our team can evaluate the overall effect on plant safety by evaluating the potential equipment failure modes of safety related equipment during the various stages of plant operation. If, for example, the selected piece of equipment does not impact the safe shutdown of the plant, potentially the piece of equipment can perform its safety function even though it may not be qualified for the environmental conditions.

Industry Experience Data Mining

- Up-to-date Industry experience and databases are available to assess instrument qualification profiles.

Location Specific Evaluations

- Rather than using a conservative broad zone to categorize the conditions a piece of equipment will be exposed to, we can determine location specific conditions. This includes the ability to perform thermal lag or radiation shielding calculations to properly account for equipment location.

Vendor Test Reports Data Mining

- A complete review of vendor qualification reports can provide additional margin. In addition, if you have acquired a new revision of a particular piece of equipment, it may be possible that new qualification data may expand upon the qualified criteria.

Seismic Qualification of Class 1E Equipment According to IEEE 344

Class 1E equipment for nuclear power generating stations is safety related equipment that is essential for safe shut down of the reactor. It has to be safe in case of seismic activity. In other words, it must be assured that the equipment performs as designed during and after a seismic event. A qualification that guarantees this can be obtained by testing the equipment on a seismic shake table. The qualification can be obtained by following IEEE (Institute of Electrical and Electronics Engineers) standard 344, which containes the recommended practices for seismic qualification of class 1E equipment for nuclear power generating stations. The practices should be used to ensure that the equipment can meet its performance requirements during and following one safe shutdown earthquake.

Vibrating Systems

Fundamental knowledge of mechanical vibrations is required when analyzing the effects of a seismic event on plant equipment. The following is a brief review of vibration theory:

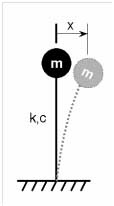

Figure 1 can be understood as a simplified schematic of a plant component, such as a pump or an electrical cabinet, mounted to the ground. During an earthquake, the ground undergoes motion, which is called base excitation. Depending on the stiffness, mass and damping characteristic of the component, the equipment will undergo a vibratory motion (response). The response can be violent if the frequency of the base excitation coincides with one of the natural frequencies of the component. This is called resonance. A resonance situation is to be avoided at all times. A seismic event consists of an irregular time history of base displacements. However, it typically covers a certain frequency range, which is based on the geographical location of the site. Consequently, the component should be designed in a way that it does not exhibit any natural frequencies in the range of the expected earthquake frequencies. Damping can dissipate some of the energy of the vibratory response. Additional damping by dashpots or frictional plants can be an option if the natural frequency cannot be sufficiently designed “away”.

Seismic Testing

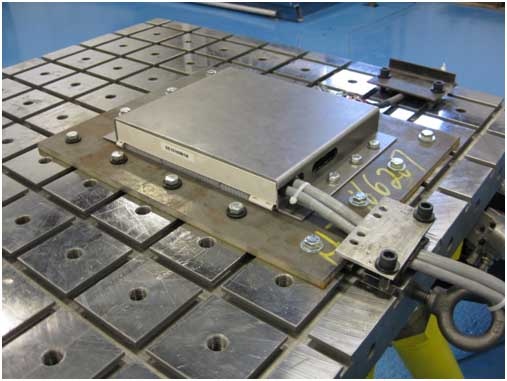

The equipment to be tested is mounted in a plant typical arrangement to the table. Before any testing, the equipment should be checked for functionality. Once the functionality is assured, either a sine sweep resonance search or a multi frequency random noise excitation is conducted to detect the natural frequencies of the equipment. This is also done to demonstrate that the mounting configuration is sufficiently rigid. For that activity the equipment is typically instrumented with a sufficient number of accelerometers. The equipment will then undergo five (5) Operating Basis Earthquake (OBE) and finally one (1) Safe Shutdown Earthquake (SSE) profiles. The Required Response Spectra (RRS) for these tests constitute a requirement to be met by the shake table time history motion. The RRS are predetermined by analysis and entered into the controller of the seismic table. They depend on various factors such as the location, the building and the bedrock. During the test, the accelerometers are used to record the Test Response Spectra (TRS). The TRS must exceed or envelope the RRS, which is typically shown by overlaid plots. The equipment shall be in operational mode during the tests and monitored for performance. A post test functionality check shall also be performed. If the equipment performs well, is free of material failures, structurally intact and the TRS exceeded the requirement, then the equipment can be classified as Class 1E. Figure 2 is a photograph of a component that was tested on a seismic shake table.