Ensure NFPA Compliance Through Corporate Level Combustible Dust Audits

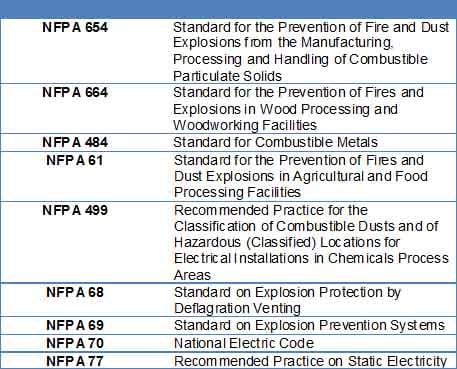

The Occupational Safety and Health Administration (OSHA) CPL 03-00-008 Combustible Dust National Emphasis Program (NEP, reissued) has been in effect since March 11, 2008. The purpose of this OSHA NEP is to reduce the risk of fires and/or explosions occurring at facilities that handle combustible particulate solids. This Instruction references other applicable OSHA regulations and is supported by related National Fire Protection Association (NFPA) Standards. These NFPA standards include:

This is where a corporate level combustible dust audit can help. These types of audits look at dust management practices and equipment including dust collectors, ductwork and other dust containers to identifying safety issues, prioritize corrective actions and determine any additional information required to mitigate fire/explosion hazards. The information they provide helps enable senior management to understand prioritized recommendations and develop a systematic action plan based on safety needs.

Although many standards are relevant, NFPA 654 Standard for the Standard for the Prevention of Fire and Dust Explosions from the Manufacturing, Processing and Handling of Combustible Particulate Solids is often the reference standard for combustible dust audits. Audit protocol items related to facility dust hazard assessments include, but are not limited to, materials, equipment and facility design, explosion protection, electrical area classification and damage control, along with administrative issues such as dust control/ housekeeping, ignition source control, training for new and veteran affected employees and contractors, Management of Change (MOC), Process Hazard Analysis (PHA), and inspections and preventive maintenance. Reports from individual facility findings and recommendations should follow a standard format, and allow for local management to obtain a clear understanding of the issues related to their specific site, as well as compare findings with plants of similar technology. Below are some of the common findings gleaned from a corporate combustible particulate/dust audit.

Common Audit Findings: Systems

- Additional testing needed

- Improved dust control/housekeeping required

- Employee/contractor training not implemented or documented

- Bonding & Grounding – other ignition source control needed

- Management of change (MOC) system not in place

- Employee not outfitted with proper personal protective equipment (PPE)

Common Audit Findings: Equipment

- Explosion protection required

- Electrical area classification needed

- Alarms and controls needed

- Maintenance and inspection programs not documented

Managing compliance is a necessity and can sometimes be perceived as an overwhelming task. The findings of a corporate audit can help the company’s internal EH&S group identify areas for improvement and where needed, initiate a revision of their current protocols, both for legacy facilities as well as new design/construction.

So, you can see, a corporate combustible dust audit is an important part of any combustible hazard/dust management program to help identify hazards, evaluate potential risks, implement safeguards and maintain compliance.