Characterizing Combustible Dusts for Explosion Prevention: Influence of Ignition Source and Particle Size

Dust is found somewhere in almost every process, and yet very few understand how dangerous it can be! A study conducted by Powder Bulk & Solids showed that between 2016 and 2020 there were an average of 31.8 dust explosions per year. Many factors influence the combustibility of dust such as particle size and moisture content, and it is also highly situational with factors such as confinement and dispersion impacting the likelihood for a dust to explode. It may be surprising how many types of dust can be explosive if the right conditions are met: these include wood, metals, food products, and pharmaceuticals, to name a few. With dust explosions still occurring every year, it is important to properly characterize dust to prevent dust explosions from happening.

Dust is found somewhere in almost every process, and yet very few understand how dangerous it can be! A study conducted by Powder Bulk & Solids showed that between 2016 and 2020 there were an average of 31.8 dust explosions per year. Many factors influence the combustibility of dust such as particle size and moisture content, and it is also highly situational with factors such as confinement and dispersion impacting the likelihood for a dust to explode. It may be surprising how many types of dust can be explosive if the right conditions are met: these include wood, metals, food products, and pharmaceuticals, to name a few. With dust explosions still occurring every year, it is important to properly characterize dust to prevent dust explosions from happening.

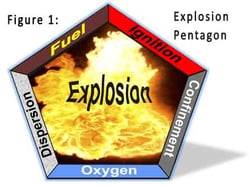

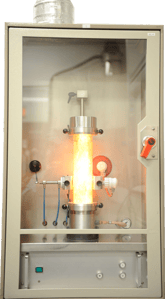

In order for a dust explosion to occur, 5 things are required: fuel, ignition source, oxidant, dispersion and confinement (see explosion pentagon, Figure 1). This differs from a fire since there are only 3 things needed in that case: fuel, ignition source, and oxidant (i.e., the fire triangle). A fire starts when a flammable material is ignited with the presence of oxygen. Now, if that flammable material is lofted (dispersed) into a dust cloud and ignited, the flame will propagate throughout the cloud while the oxygen keeps the fire burning (see Figure 2). Within a confined space, the pressurized gas from the ignition will exert itself leading to an explosion.

In order for a dust explosion to occur, 5 things are required: fuel, ignition source, oxidant, dispersion and confinement (see explosion pentagon, Figure 1). This differs from a fire since there are only 3 things needed in that case: fuel, ignition source, and oxidant (i.e., the fire triangle). A fire starts when a flammable material is ignited with the presence of oxygen. Now, if that flammable material is lofted (dispersed) into a dust cloud and ignited, the flame will propagate throughout the cloud while the oxygen keeps the fire burning (see Figure 2). Within a confined space, the pressurized gas from the ignition will exert itself leading to an explosion.

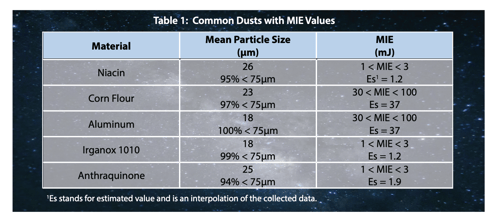

There are many ways to characterize the combustibility of dust, and they typically revolve around studying the sensitivity of the dust to the five categories on the explosion pentagon. Some dust clouds are more sensitive than others where even low energy levels, such as static shock, can ignite the material. One way to determine a material’s sensitivity to ignition is by performing a Minimum Ignition Energy (MIE) test. The purpose of this test is to identify how much energy is needed to ignite a given material. During this test, the equipment disperses the dust to create a dust cloud, while simultaneously discharging an electrical spark through that cloud. The spark can range from 1 mJ to 1000 mJ allowing it to represent various types of ignition sources. Depending on the findings, protective measures such as grounding and bonding can be implemented to decrease the risk of explosion. Some common explosible dusts are shown in Table 1. The MIE for corn flower or aluminum is approximately 37 mJ while the values for niacin, irganox 1010, and anthraquinone are much lower and are between 1 and 3 mJ. From a hazard perspective, the material with the lowest MIE should be considered when designing equipment or developing procedures because these have the highest likelihood of an unwanted explosion. The lower the MIE, the greater the risk.

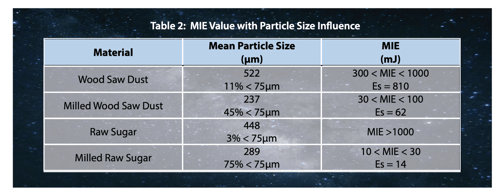

Dusts can be harder to characterize than vapors and gases since they have additional properties that can influence their sensitivity to ignition. This can be due to the composition, moisture level, particle size, and morphology of the material. Most regulatory bodies define a dust as being a powder that has a particle size no larger than 500 μm. Typically, a dust’s sensitivity to spark ignition decreases as the particle size increases. Wood and sugar dusts are perfect examples of this trend. Table 2 shows how the MIE value of two products differs as the particle size changes.

The various material properties of dust and potential environmental factors should be considered when assessing the risk of a combustible dust. Minimum ignition energy and impact of particle size are two examples. Unsure if the material in your process is a dust hazard? Let us help identify the proper scope of testing and/or if a Dust Hazards Analysis (DHA) is needed at your facility. For more information, please contact our Combustible Dust team at dust@fauske.com or click the button below.