MIE Testing for Combustible Dust Safety: With or Without Inductance?

By the Combustible Dust Safety Team, Fauske & Associates

We know we have discussed the Minimum Ignition Energy (MIE) test before, but given a recent uptick in questions on the subject, we thought it was a good time to “dust” off the topic and take another look.

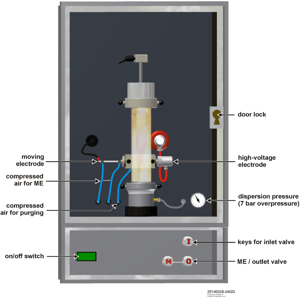

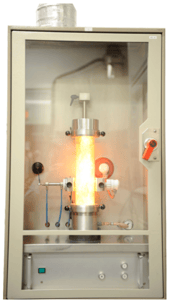

The MIE test determines the lowest amount of spark energy that is required to initiate an explosion of a dust in a suspended cloud. It is performed using ASTM E2019, “Standard Test Method for Minimum Ignition Energy of a Dust Cloud in Air” or EN13821 “Potentially explosive atmospheres — Explosion prevention and protection — Determination of minimum ignition energy of dust/air mixtures”. These methods provide procedures for performing laboratory tests to determine the minimum ignition energy of a dust cloud.

The MIE test determines the lowest amount of spark energy that is required to initiate an explosion of a dust in a suspended cloud. It is performed using ASTM E2019, “Standard Test Method for Minimum Ignition Energy of a Dust Cloud in Air” or EN13821 “Potentially explosive atmospheres — Explosion prevention and protection — Determination of minimum ignition energy of dust/air mixtures”. These methods provide procedures for performing laboratory tests to determine the minimum ignition energy of a dust cloud.

In both standards, the MIE tests can be performed with or without “inductance” - which Merriam-Webster.com defines as: “A property of an electric circuit by which an electromotive force is induced in it by a variation of current either in the circuit itself or in a neighboring circuit”. So, what does that really mean? Simply put, testing “WITH inductance” simulates the longer duration discharges from electronic circuitry that can occur from machines or control equipment (essentially a spark from short in a wire or electronic equipment) or mechanical sparks. Testing with inductance is a more conservative approach that ensures you have the lowest MIE value possible for your material.

Testing WITHOUT inductance better simulates discharges from “pure” and “ideal” static electric sources (the build-up of a charge on a surface resulting from contact with other surfaces – e.g. pouring or rubbing). The spark duration is shorter when dealing with “pure” static electric sources, so the determined energy levels are typically less conservative.

This data is critical when considering what could happen if a dust cloud is exposed to a spark. A build up of static electricity is a fairly common occurrence in many industrial processes. Simple movements or activities such as conveying, sieving or pouring/transferring material from container to container can be enough to cause a spark, and, that could be all it takes – one spark from a short in a wire or a discharge from a “pure” static electric source, plus the right air to dust (read fuel) mixture, to cause ignition.

Knowledge of the MIE of a dust is also helpful in housekeeping situation as it can help facilities identify proper tools for safe clean up, as well as assist in the safer design of dust collection equipment. Additionally, knowledge about the MIE level is important for establishing proper grounding and bonding protocols and designing ignition source avoidance methodologies.

Of course, the data provided by MIE testing can be even more useful when combined with a dust hazard analysis or DHA which is a systematic evaluation of the hazards involved in the dust handling or generating process. Either way it is critical to take a look at your own facility and process to determine the best iteration of the test for your specific scenario needs.

After a review of your facility, if you are certain of the type of equipment being used in your process, or are confident that you are only dealing with electrostatic sparks, then you can determine if the MIE should be conducted with or without inductance. If, you are only concerned about static-electric sparks, then likely the MIE test without inductance should be performed. If, however, you are worried about sparks from electronic circuitry, other ignition sources or you wish to publish the MIE value on a Safety Data Sheet, then the more conservative MIE method using inductance in the circuit is more appropriate.

This is intended to inform about the differences between MIE testing with and without inductance. If there is any question about which form of the test should be used, you should consult a dust expert for guidance or use the conservative approach.

For more information, please contact us at dust@fauske.com.