Development of the Source Term Analysis Tool SAS4A-FATE For Lead- and Sodium-Cooled Fast Reactors

by S. J. Lee*, C. Y. Paik*, T. Q. Hua°, A. Moisseytsev°, A. Karahan°, A. M. Tentner°, T. Sofu°, J. Liao+, P. Ferroni+

*Fauske & Associates, 16W070 83rd Street, Burr Ridge, IL 60527, USA

°Argonne National Laboratory, 9700 Cass Avenue, Lemont, IL 60439, USA

+Westinghouse Electric Company, LLC, 1000 Westinghouse Drive, Cranberry Township, PA 16066, USA

In a March 2018 blog/Technical Bulletin Fauske & Associates (FAI) titled "SAS4A-FATE: A Mechanistic Source Term Analysis Tool for Advanced Reactors" by Sung Jin Lee, Senior Consulting Engineer, Fauske & Associates:

"Liquid Metal Reactors (LMRs) are promoted as having safety advantages over Light Water Reactors (LWRs) in terms of reduced likelihood of core damage and containment failure. LMR’s are also promoted as being capable of addressing markets such as process and district heat applications. Consistent with these features, a goal for LMR licensing is to reduce the Emergency Planning Zone (EPZ) compared to an LWR of comparable size.

Justification of a reduced EPZ requires analytical capabilities for Mechanistic Source Term (MST) assessments to predict the system’s response to a broad spectrum of accidents with significant variations in time-scale and consequences. An MST assessment attempts to realistically model the release and transport of radionuclides from their source to the environment for a specific scenario, while accounting for retention and transmutation phenomena along with any associated uncertainties.

Safety analysis of LMRs must consider a wide range of initiating events which cause an imbalance between heat production and removal..."

Fauske & Associates (FAI) was awarded a GAIN voucher to collaborate with Argonne National Laboratory to develop an MST analysis capability for liquid-metal cooled reactors. This SESAME International Workshop technical paper describes the results of this collaboration. The abstract is below.

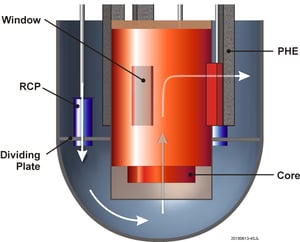

| ABSTRACT Fauske & Associates (FAI), Argonne National Laboratory (ANL), and Westinghouse Electric Company LLC (Westinghouse) are collaborating within the program “Development of an Integrated Mechanistic Source Term Assessment Capability for Lead- and Sodium-Cooled Fast Reactors”. This program aims at developing a computational framework for predicting radionuclide release from a broad spectrum of accidents that can be postulated to occur at Liquid-Metal Cooled Reactor (LMR) facilities. Specifically, the program couples the transient and severe accident analysis capability of the SAS4A/SASSYS-1 code developed by ANL with the radionuclide transport analysis capability of the FATETM (Facility Flow, Aerosol, Thermal, and Explosion) code developed by FAI. The testing of both the individual codes and of the coupled system is performed on a generic Lead Fast Reactor (LFR) design. That is intended to capture the key differences between the LFR and Sodium Fast Reactor (SFR), around which the SAS4A/SASSYS-1 code has historically been developed, and from which the coupled code inherits some features requiring modification before application to LFR systems. Using this approach, a computational framework applicable to both LFR and SFR systems is obtained, which will assist LMR developers in performing a realistic, scenario-dependent mechanistic source term (MST) assessment not only to strengthen their safety case, but also to support easier siting and claims on reduced emergency planning zone requirements. This paper discusses the work performed to adapt the SAS4A/SASSYS-1 and FATE codes to LFR technology, the code coupling method, and the results from some LFR test cases. |

If you are interested in reading the paper in its entirety, click below.