|

| One of FAI’s experimental laboratories |

Day to day operation of an industrial plant requires continuous monitoring and adjusting of the numerous components that enable the plant to operate safely and efficiently. When questions arise or problems occur, the tools of choice are usually detailed computer codes, hand calculations, separate effects testing and engineering judgment. But, when schedules are tight and analysis via computer codes isn’t possible and/or is costly, the best course of action is to perform a scaled or full-sized test that replicates the exact set of conditions that are at issue. Actual tests provide real-life results.

Comprehensive experimental laboratories provide the ability to investigate a wide range of single and two-phase fluid flow conditions and configurations. Issues such as waterhammer, gas transport, containment sump performance and vortex suppression are just a few of the items that can be evaluated. The following are just a few examples of testing completed by FAI safety consulting engineers in state of the art labs.

Gas accumulation during a two-phase flow experiment

Gas accumulation during a two-phase flow experiment

Air Intrusion

These are experiments to test the nature of air intrusion of an emergency core cooling system under design basis accident conditions.

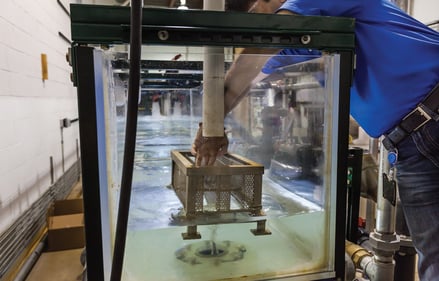

Containment Sump Performance

Experiments have been performed in support of GS-191 resolution in our Flume Facility. The Flume Facility has been used to evaluate:

- Debris erosion rate quantification

- Debris interceptor design/validation testing

- Head loss testing through filters

Waterhammer-in-FAI-Flume-Lab

FAI Flume Facility

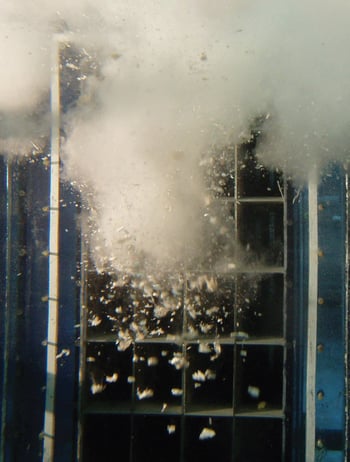

Waterhammer

Experiments and analyses of waterhammer (both steam-water and noncondensable/gas-water) are performed by engineers. These studies also evaluate the force imbalance across piping systems that can cause loads sufficient to challenge the piping supports and the piping itself.

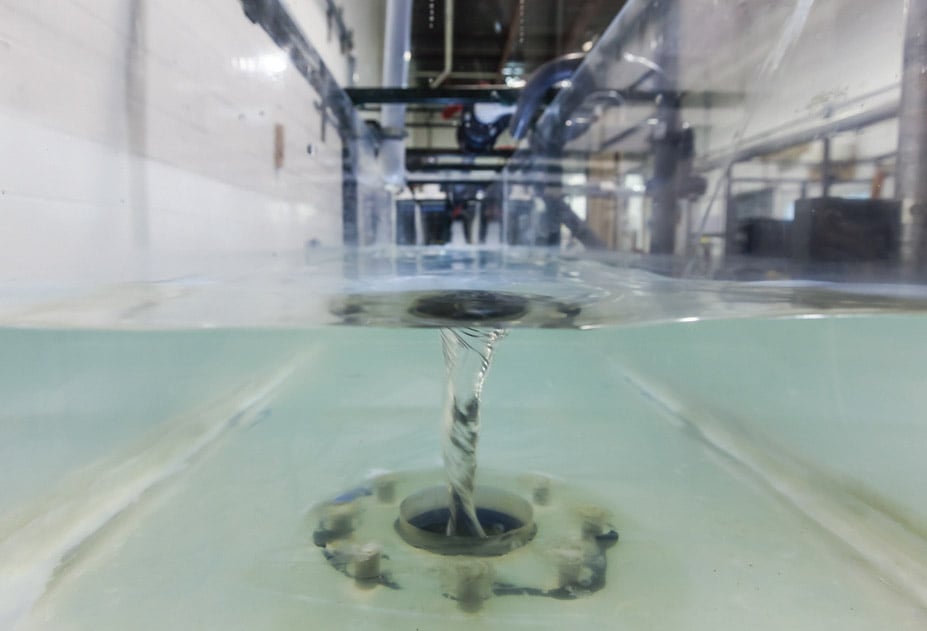

Vortex Behavior

Experiments are performed to evaluate vortex behavior under a variety of conditions:

- Experimental quantification of vortex correlations for plant and system specific correlations

- Vortex suppressor design and validation for piping systems and tanks, including evaluation of the VEXTORTM vortex suppressor for plant specific applications.

|

|

| Vortex forming in a Flume experiment | Vortex suppression demonstration with VEXTORTM |

For questions regarding investigative needs, contact us today!