FREE Users Training- Process Safety Equipment & New Parts News/Catalog

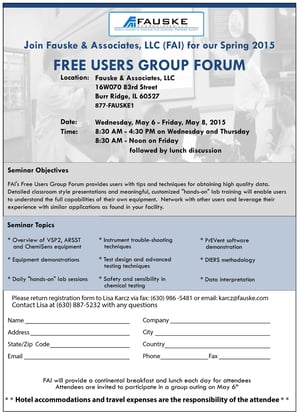

Do you understand the full capabilities of your own process safety test equipment? Do you want a greater understanding of how to best use equipment for your particular facility's needs? Join us for the FREE Users Group Forum May 6-8 at our Burr Ridge (Chicago area), Illinois location.

In addition, did you know we "got parts"? Yep, hundreds and hundreds of them. Everything from customized test cells to versatile equipment such as the VSP2TM, ARSSTTM, software and ARC Bombs. We have an online parts store but needed to talk more directly to our parts customers, per their request. So, we've created both a new Parts Points Newsletter and a Catalog to ensure that our Parts Service Team and Parts Manufacturing Team are accessible and responsive to need and demand.

We tend to blog about new findings, events and procedures to improve facility and plant safety - for the nuclear, industrial and chemical process areas, but wanted to show some love to all you parts users out there. Please also enjoy the article: "An Alternative Methodology Addressing United Nations' (UN) guidelines for Self-Reactive Substances The Easy and Verified Way" included in the newsletter.

Please join us for this Free Users Group Forum. It follows our popular "Relief System Design Course" next week, May 4-5 taught by Hans K. Fauske (for all you last minute warriors). This course teaches users to understand the up-to-date DIERS vent sizing methodologies and models, as well as the role of single and two-phase flow in venting behavior. It also teaches users to perform vent sizing calculations using the correct models and methodologies, apply adiabatic calorimetry data and to use hands-on techniques and "rules of thumb" to ensure that realistic vessel and vent size conditions are specified.

Please join us for this Free Users Group Forum. It follows our popular "Relief System Design Course" next week, May 4-5 taught by Hans K. Fauske (for all you last minute warriors). This course teaches users to understand the up-to-date DIERS vent sizing methodologies and models, as well as the role of single and two-phase flow in venting behavior. It also teaches users to perform vent sizing calculations using the correct models and methodologies, apply adiabatic calorimetry data and to use hands-on techniques and "rules of thumb" to ensure that realistic vessel and vent size conditions are specified.

As always, we appreciate your input and discussion regarding safety testing and engineering solutions. afauske@fauske.com, www.fauske.com

#nuclear plant, #chemical reaction