Got ERS? Are Emergency Relief Systems Missing From Your Relief System Design?

Fauske & Associates

3 min read

How do you ensure or work to continuously increase plant safety? One sure way is in the appropriate design of emergency relief systems (ERS). ERS are needed for processes where a thermal hazard exists. A thermal runaway reaction can be an unacceptable over-pressurization of the system that could result in a dangerous situation. Do you have a turnkey approach through a combination of testing and analysis, to check and address your ERS?

How do you ensure or work to continuously increase plant safety? One sure way is in the appropriate design of emergency relief systems (ERS). ERS are needed for processes where a thermal hazard exists. A thermal runaway reaction can be an unacceptable over-pressurization of the system that could result in a dangerous situation. Do you have a turnkey approach through a combination of testing and analysis, to check and address your ERS?

Your arsenal should include:

Chemical Testing

- Tests should be performed to characterize the runaway reaction under the upset conditions of interest.

- Are your temperature and pressure data measured and scaled to the process vessel?

- Are you armed with state of the art tools such as Vent Sizing Package 2TM (VSP2) and Advanced Reactive System Screening ToolTM (ARSST)?

Process Simulation

- Have you evaluated the required vent size? Tools such as Practical Emergency Vent Sizing Software (PrEVent) are necessary.

- The design of the existing or new ERS should be analyzed with commercial transient analysis codes for its performance in handling the effluent.

- Depressurization of transient fluid forces should be computed by tracking momentum flux, thrust and pressure waves.

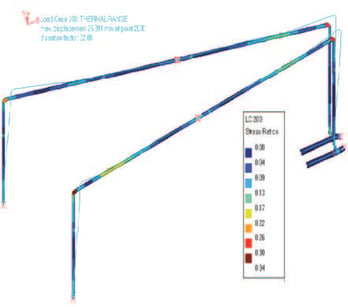

Structural Design

Structural Design

- The ERS design should be evaluated in a structural analysis code.

- Pipe support design should be evaluated and reviewed.

- Dynamic stress analysis of the ERS should be conducted.

- Code compliance should be verified against specific requirements, e.g. ASME B31.3, EN-13480, and others.

Additional Considerations

- Effluent handling (quench tank, knockout drum) evaluations.

- Dispersion modeling - can be a very important and often overlooked component to the ERS program.

For more ideas, questions or discussion on a comprehensive Emergency Relief System Design Plan, please contact us.