When calorimetry tests involve air sensitive reagents there are a variety of techniques available for handling them. The particular technique or procedure depends on the nature of the chemical and type of test being performed (open vs. closed VSP2 test, for example).

The most common method for inerting the atmosphere of a closed VSP2 test cell is to evacuate the headspace and backfill it with low pressure (~10 psig) nitrogen several times prior to leaving the headspace evacuated for charging the sample through the VSP2 fill line. To maintain an inert atmosphere when withdrawing a liquid into a syringe for charging to the VSP2, no air is allowed in the syringe (or it is purged out prior to charging). After installing the syringe on the VSP2 Luer-lok elbow adapter and charging the contents to the initially evacuated test cell, the plunger is pulled up partially (to about 5 to 10 ml, depending on the material and quantity) and then pushed back down, to flush the fill line of any holdup. If the sample is volatile, a two-way stopcock is commonly used to isolated and prevent evaporation from the syringe to permit accurate weight measurements.

|

| Figure 1. VSP2 fill tube connection with Luer-lok elbow and 3-way stopcock for addition of air sensitive reagents |

For liquid samples with no tolerance for even a very small amount of air, a three-way stopcock can be installed on the Luer-lok elbow to permit feeding low pressure nitrogen from the middle (side) port, as shown in Figure 1. With this set-up, nitrogen is first fed to inert the Luer-lok elbow. Prior to charging the liquid (from a syringe equipped with a two-way stopcock mounted in the upright position), nitrogen is directed upward to inert the small space between the syringe and the three-way stopcock. To charge the sample, the three-way stopcock is positioned to permit flow from the syringe to the VSP2 fill port. After charging the sample through the straight-through pathway, nitrogen from the side branch of the stopcock is used to backfill the syringe for flushing the fill line. This has been used for samples which are highly sensitive to air or moisture.

If reagents are air sensitive and not contained in a bottle with a septum, normally a nitrogen-inerted glove box is used to charge either the test cell (which may be capped off for running a closed system test) or a syringe (equipped with a stopcock). Once outside of the glove box, the above methods are useful to maintain an inert atmosphere as a sample is charged to the test cell from a pre-loaded syringe. For open system tests, either the entire test cell and heater assembly can be installed into the insulated containment vessel in the glove box, complete with the lid, or perhaps only the vented test cell, depending on the nature of the reagent. In the latter case, a Swagelok cap may be loosely placed on the vent line to keep air out, and the cap is removed just prior to sealing the containment vessel. In this case, one may pad the containment vessel with Argon to help maintain inerting while the test cell/heater assembly is bundled up and placed in the containment vessel.

|

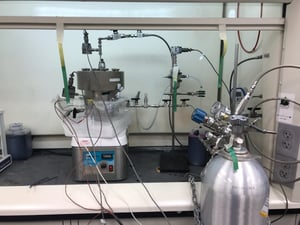

| Figure 2. Custom VSP2 test setup for air sensitive and toxic gas reagents |

For handling higher vapor pressure liquids combined with air sensitivity, a Hamilton gas-tight syringe may be used (depending on the pressure). There is a newer model available which includes an integrated Luer-lok stopcock and a plunger lock to prevent the plunger from coming out, Hamilton’s Sample Lock. This adds a safety feature which nevertheless must be used within the appropriate pressure rating specified for the syringe. The commonly used stainless steel piston, recommended by FAI for injection of liquids against high pressures (rated up to 1000 psi), may be loaded in a glove box for air sensitive reagents.

Figure 2 shows a custom setup for safe addition of a colorless toxic gas reagent. The photo was taken prior to the start of the test, during which the sash would have been at the appropriate safe height. Wet pH paper is strategically positioned as a backup indicator to handheld sensor instruments. Note the VSP2 vessel is easily cooled using a tray of dry ice with no interruption of stirring. Gas addition is quantified by measuring the pressure changes in the known volume of a small accumulator bomb on the valved feed.

The VSP2 allows for creative and safe test design. We are happy to share our experience on how to make the best use of this versatile instrument. To get any questions answered, please reach out to contact the Fauske Team below!