Battery safety is a much-discussed topic, and its importance continues to remain front and center as the energy storage industry continues to expand. Fauske & Associates flammability team actively supports customers with battery safety testing. Up to now we have primarily focused on flammability analysis of the gas that is released during battery thermal events. We experimentally determine the LFL, Pmax, and Kg as required by industry accepted standards such as ANSI/CAN/UL 9540A Ed. 4 which references a number of other standards (e.g., ASHRAE, ASTM, EN, ISO, NFPA and Canadian standards). These data are used to ensure the enclosure ventilation system and explosion relief panels are adequate for the installation.

Battery safety is a much-discussed topic, and its importance continues to remain front and center as the energy storage industry continues to expand. Fauske & Associates flammability team actively supports customers with battery safety testing. Up to now we have primarily focused on flammability analysis of the gas that is released during battery thermal events. We experimentally determine the LFL, Pmax, and Kg as required by industry accepted standards such as ANSI/CAN/UL 9540A Ed. 4 which references a number of other standards (e.g., ASHRAE, ASTM, EN, ISO, NFPA and Canadian standards). These data are used to ensure the enclosure ventilation system and explosion relief panels are adequate for the installation.

Historically, Fauske and our customers have found adiabatic calorimetry to be a useful method for evaluating thermal stability of battery materials. More recently a number of our calorimetry users have inquired on how they might adapt their existing VSP2 calorimeter for testing of battery components, from cell sizes to large assemblies, and some research organizations have been doing this for a number of years already.

Of course, battery testing instruments such as the THT ES-ARC have been available for years, but our customers indicate there is interest in applying the versatile VSP2 as a complementary technology option. This article shares results from a successful proof-of-concept “scoping” experiment using the VSP2 to study the thermal runaway of a battery exposed to external heating. Please contact us to learn about more recent developments.

Detailed Description of Scoping Test:

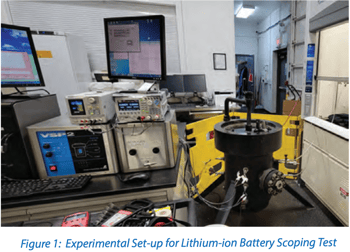

The standard VSP2 system was supplemented with an additional power supply and electrical load device, which for convenience were controlled separately from the VSP2 software. Also, for added safety the standard 4-liter containment vessel was replaced with a larger pressure vessel available in the FAI flammability lab. Results demonstrate the efficacy of the VSP2 for analyzing battery explosions, and the method is scalable to larger batteries.

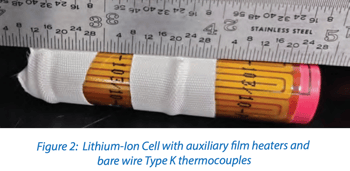

One 2500 mAh capacity Lithium-ion cell of an 18650 cylindrical format was installed into a custom heating assembly and placed inside of a 70L pressure vessel under ambient conditions. Figures 1 to 3 show key aspects of the test setup.

One 2500 mAh capacity Lithium-ion cell of an 18650 cylindrical format was installed into a custom heating assembly and placed inside of a 70L pressure vessel under ambient conditions. Figures 1 to 3 show key aspects of the test setup.

A programmable DC power supply, a programmable electrical load, and a custom LabVIEW program were used to pre-condition the lithium-ion cell. Pre-conditioning consisted of a charging phase followed by a discharging phase and finally a charging phase to 100% state of charge (SOC) per the manufacturer’s specifications.

The VSP2 control software was configured to heat the lithium-ion cell at a constant rate from ambient to 350°C. The temperature, pressure, and lithium-ion cell voltage were measured and recorded. Additionally, the auxiliary and guard heater control power were recorded. The lithium-ion cell voltage was measured using the custom LabVIEW program and pre-conditioning equipment while the VSP2 was used to record the temperatures and pressure and control the heaters.

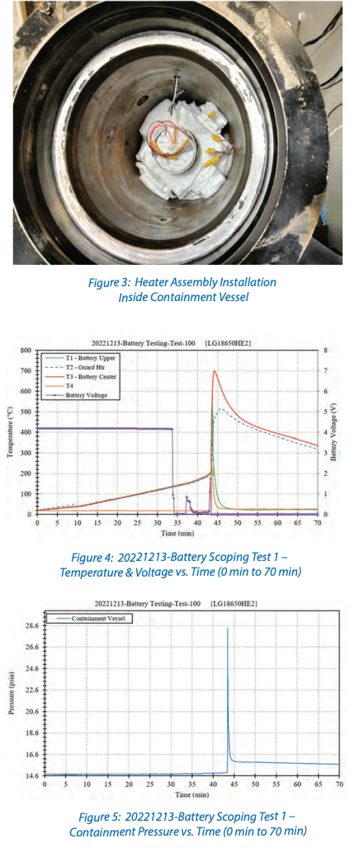

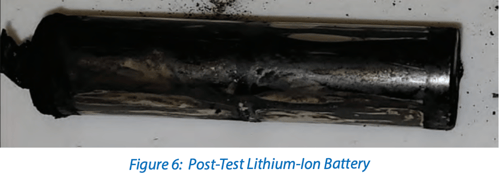

Data on temperature and pressure are shown in Figure 4 and Figure 5, respectively. (Data files from the VSP2 PC and LabVIEW PC were manually overlayed since automatic data syncing was not available.) At a cell surface temperature of 135°C, the cell voltage dropped sharply from 4.2 volts to 0 volts. At about 37 min at a cell surface temperature of 148°C, a small but noticeable thermal event (not discernable on the scale of Figure 4) was observed coincident with a slight increase in containment vessel pressure, marking the moment of cell venting. During this event, the voltage of the cell increased to approximately 1 volt and then gradually decayed towards 0 volts. Following this off-gassing event, the temperature rise rate of the cell surface temperature began to increase above the imposed heating rate of the main (aux) heater and the exothermic runaway proceeded to accelerate leading to a spike in temperature and pressure at about 43 min. The containment vessel pressure reached a maximum of 13.6 psig. Following the pressure spike, the outer surface temperature of the battery measured 583°C at the thermocouple position near the positive terminal and a maximum recorded temperature of 698°C at the center position.

Data on temperature and pressure are shown in Figure 4 and Figure 5, respectively. (Data files from the VSP2 PC and LabVIEW PC were manually overlayed since automatic data syncing was not available.) At a cell surface temperature of 135°C, the cell voltage dropped sharply from 4.2 volts to 0 volts. At about 37 min at a cell surface temperature of 148°C, a small but noticeable thermal event (not discernable on the scale of Figure 4) was observed coincident with a slight increase in containment vessel pressure, marking the moment of cell venting. During this event, the voltage of the cell increased to approximately 1 volt and then gradually decayed towards 0 volts. Following this off-gassing event, the temperature rise rate of the cell surface temperature began to increase above the imposed heating rate of the main (aux) heater and the exothermic runaway proceeded to accelerate leading to a spike in temperature and pressure at about 43 min. The containment vessel pressure reached a maximum of 13.6 psig. Following the pressure spike, the outer surface temperature of the battery measured 583°C at the thermocouple position near the positive terminal and a maximum recorded temperature of 698°C at the center position.

The heaters were disabled, and the vessel contents were allowed to cool down. A gas sample of the containment vessel headspace was collected for later analysis. Figure 6 shows the battery post-test.

We are continuing to improve our test method and hardware options, keeping in line with established standards, and look forward to presenting more data and information in the near future. Please contact us for further details.

References

J. P. Burelbach, ARSST Experiments to Evaluate Solvent Compatibility with Stabilized Lithium Metal Powder (SLMP™), Fauske & Associates, 211th Meeting of the Electrochemical Society (ECS), Chicago, Illinois, USA, May 6, 2007

M. V. Yakovleva, B. Fitch, Y. Li, and Y. Gao, Progress on Stabilized Lithium Metal Powder (SLMP™), an Enabling Material for a New Generation of Li-ion Batteries, FMC Corporation, 24th International Battery Seminar & Exhibit, Florida (March 19-22, 2007)

C-Y Jhu, Y-W Wang, Chi-Min Shu, J-C Chang, and H-C Wu, Thermal explosion hazards on 18650 lithium-ion batteries with a VSP2 adiabatic calorimeter, NYUST, JTJC, ITRI (Taiwan) Journal of Hazardous Materials 192 (2011) 99–107