Operators in the power generation, oil & gas and petrochemical markets face continuous pressure to maximize the availability of their cost-intensive capital equipment while minimizing the associated operating costs. For those seeking an optimal balance between operability and cost, Maintenance Optimization Modeling provides a simple but comprehensive solution that is based on probabilistic and statistical analysis of your most important plant assets.

Experience

Given the scope of investment required in many of our projects, we frequently deploy probabilistic applications and model development as a core business. We believe in areas such as probabilistic risk assessment so much we employ more than 60 probabilistic risk practitioners in our global workforce today. We have invested in the establishment and use of the industry frameworks necessary for the efficient implementation of probabilistic modeling.

"Because of our extensive experience with the scope and complexity of nuclear power generation modeling, our engineers are able to use those long-proven sector tools to simplify and customize solutions," states Fauske & Associates, LLC Operations VP Zachary Hachmeister. "We possesses expertise in the power generation and energy sectors – including asset management of heavy capital equipment such as heat exchangers, heavy piping and generators. Based on that expertise, we can offer a proven comprehensive solution that includes probabilistic modeling and statistical analysis of mechanical or electrical assets, piping, storage, transmission distribution, human factors, and supervisory control and data acquisition (SCADA) instrumentation."

Hachmeister adds: "We have enjoyed recent success in training and implementing probabilistic modeling on natural gas assets. The modeling included a strategic solution that reviewed components, data, and human factors. Any standard asset inventory can be typically modeled within a few weeks."

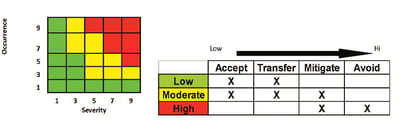

A system Failure Modes and Effects Analysis (FMEA) is a structured process used to identify the ways a process can fail,

estimate the risk associated with failure and prioritize actions to reduce the risk.

Whether you’re in the power generation, oil & gas, or petrochemical

industry, a Maintenance Optimization Modeling solution can help

maximize equipment availability while minimizing plant capital costs.

Services

FMEA

A system process FMEA is used to identify potential “pinch points” or vulnerabilities within industrial applications and, from this, propose statistical analyses that facilitate system maintenance.

Modeling

A Maintenance Optimization Modelling team can develop a probabilistic modeling solution for a facility’s operations process. The context of the model will be dependent on the data inputs available and utilized. The intent of this model is to develop a system asset management program to enhance the performance and cost effectiveness of the maintenance of your facility operations.

This effort will produce a mathematical model of the desired process and associated components in order to define process reliability and estimated system downtime. This information will be used to identify and justify optimal maintenance intervals.

For more information, please contact nucleargroup@fauske.com or 630-323-8750. If you are interested in learning more about probabilistic risk assessment, review our PDF on assessing uncertainties by clicking the button below.