By: Megan Piotrowski, Lab Chemist, Fauske & Associates, LLC

The Flammability Team recently acquired a new toy – the Discovery Hybrid Rheometer (DHR) from TA Instruments. Unlike commonly used viscometers, rheometers can make both viscosity and viscoeleastic measurements. The DHR can measure both a fluid’s resistance to flow and how it behaves before flowing. Even further, the Discovery HR-2 achieves this with some of the highest precision and sensitivity in the field.

Rheology Basics Figure 1 - DHR-2 from TA Instruments http://www.tainstruments.com/dhr-2/

Rheometers characterize fluids and solids in terms of flow and deformation. These measurements are useful for a wide range of chemical industries including polymers and solvents, food and agriculture, oil and petroleum and many others. Viscosity, in particular, is an important measurement of flow. It determines the thickness of a material and how it can be applied and manipulated during processing. Viscosity is also an important safety consideration. From an environmental standpoint, if a material is too thin, it may leach into soil or groundwater, causing contamination.

On the other end of the spectrum, there are viscoelastic property determinations. When a material is neither completely solid nor completely liquid, it’s called viscoelastic. Viscoelastic properties like complex modulus and phase angle are measured by rheometers, and they help determine these solid or liquid-like characteristics. They measure the stiffness or toughness of a material as well as its pourability. These properties often come into play when materials have the same viscosity but behave differently. They help characterize these differences and can aid in product formulation to quality control and assurance.

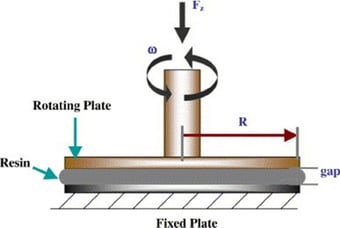

Figure 2 – Parallel Plate with Sample

https://www.researchgate.net/figure/236007972_fig10_Figure-16-Parallelplate-geometry-setup-60

Rheometers use the forces of shear stress and shear strain to make the abovementioned and other important material characterization measurements. A rheometer accomplishes this by applying shear stress and strain forces to two metal plates with a sample sandwiched between them. When calculating viscosity, the rheometer applies a continuous rotational force in one direction to the top plate. When calculating modulus, or viscoelasticity, however, the plate rotates back and forth, or oscillates. The DHR rheometer allows the user to easily switch between rotational and oscillation modes in order to make viscosity or viscoelastic measurements.

DHR Series Specifics

Due to the importance of rheological measurements, TA Instruments designed their Discovery Hybrid rheometers to be as precise and accurate as possible. The hybrid systems achieve this through a mix of patented and patent-pending innovations such as an optical encoder dual reader, advanced drag cup motor, second-generation magnetic bearing, New True Position Sensor and an Active Temperature Control. These features contribute to better displacement measurements, reduced noise, smoother motor acceleration, reduced friction, higher gap accuracy and the most precise control of upper and lower plate temperatures. As a result of these advancements, the Discovery Hybrid rheometer is able to handle testing over a wide range of conditions while producing highly accurate and reproducible data.

Rheology and Process Safety

As the Flammability Group receives a wide range of chemicals for process safety related testing, the DHR-2 is a great addition to our capabilities. For instance, customers and clients can now include viscosity measurements in their Safety Data Sheet (SDS) completion needs. In terms of process safety, these properties are often vital when devising scale-up procedures. Viscosity and viscoelasticy often change with heating and mixing, and when mixing large batches, it’s important to consider whether stirring and storage of the material could be hindered by these changes. For instance, in the case of certain chemicals, if stirring were to stop or slow down significantly, reactions may stop before completion. This may not only impact the integrity of the batch, but it could also impact the safety of the workers and operators around it. Therefore, it’s important to take viscosity and viscoelastic measurements into account when modifying or implementing chemical processes and their safety considerations.

For more information, contact us at info@fauske.com. www.fauske.com

References

TA Instruments website, Discovery Hybrid Rheometers brochure:

http://www.tainstruments.com/wp-content/uploads/dhr_brochure.pdf

Rheology Basics: Introducing the Malvern Kinexus a Practical Measurement

Perspective by Dr. Adrian Hill; http://www.atascientific.com.

au/eventsandtraining /eventsandtraining /wp-content/uploads/2013/01/

Rheology-Basics-Introduction-to-Rheology-and-Kinexus.pdf