Nuclear Safety and Chemical Process Safety - a 35 Year Perspective

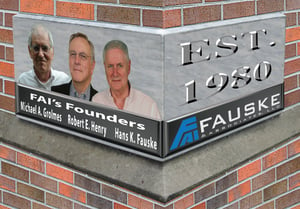

In 1980, Hans K. Fauske, D.Sc., Robert E. Henry, Ph.D. and Michael Grolmes, Ph.D. left Argonne National Laboratory to form Fauske & Associates, (FAI). In honor of the 35th anniversary of the company, our own Sara Peters sat down to briefly interview the three founders, gaining insight into the beginnings of FAI, and their thoughts on the company and industry today.

Reasons that are frequently cited as contributors to longevity of business are framed with words such as flexibility, adaptability, customer focus, innovation, quality of service, excellent employees and strong culture. It is evident in their responses that these elements along with an ongoing commitment to safety have been a key factor in keeping FAI in business for such an impressive length of time.

I often joke that I'm the "Penny" to the "Sheldons" and "Leonards" around here at FAI, having just a Public Relations undergrad degree  and an MBA compared to these amazing science guys wearing white hats and capes (depending on your genre preference). Seriously though, I learn mind blowing stuff every day and am very glad these people exist to help make our world safer and better. Wherever a facility exists mixing chemicals, manufacturing, producing combustible dusts, providing nuclear power, etc., there is a clear need for super-engineers to assess and test risk. These are the guys with the insatiable curiosities and problem solving behaviors. And, I'm thanking our leaders today. Hope you will, too. :)

and an MBA compared to these amazing science guys wearing white hats and capes (depending on your genre preference). Seriously though, I learn mind blowing stuff every day and am very glad these people exist to help make our world safer and better. Wherever a facility exists mixing chemicals, manufacturing, producing combustible dusts, providing nuclear power, etc., there is a clear need for super-engineers to assess and test risk. These are the guys with the insatiable curiosities and problem solving behaviors. And, I'm thanking our leaders today. Hope you will, too. :)

Q: What customer need were you trying to fulfill when you founded FAI?

A:

Dr. Fauske: I think the customer need, just generalizing, would be in the nuclear and chemical process industry. We had been awarded a contract on the DIERS (Design Institute for Emergency Relief Systems) work before we left Argonne, so that would fit into the chemical industry. And, we were also interested in and involved in the nuclear fast reactor development, particularly CRBR and the German prototype, SNR. Then, of course, the Three Mile Island incident (TMI-2) happened in 1979 and Dr. Henry was heavily involved in that. So, that really represents both the chemical and nuclear industries.

Dr. Henry: I was consulting for the Canadian utility, Ontario Hydro, while I was at Argonne, with Argonne’s knowledge, so even before Three Mile Island, we were doing things nuclear related that people were coming to us saying ‘we want you specifically to work on this’. Well, that is difficult to continue to do inside the framework of Argonne. Then, as Hans said, when the Three Mile Island incident happened I got involved doing work for Argonne, going out to the west coast every Sunday night to EPRI, and then flying back on the red-eye every Wednesday night. I did that for three months, and I could see that there were a lot of things that our expertise could help these people with on the industry side. So, there was a chemical need and a nuclear need that were very clear to us.

Q: What made you decide to break away from Argonne to form your own company?

A:

Dr. Fauske: Besides the things already mentioned, my answer is generally that it was about time to follow family tradition. Most of my family were all in business, so I decided it was about time to leave and become my own boss for a while. That allowed me to do things that you otherwise couldn't do at the national laboratory.

Dr. Henry: Once I got involved in Three Mile Island, I could see there was going to be a lot of other things that the industry wanted to do and we wanted to get involved in it personally. It has been a tremendous amount of fun. It's also been a lot of pressure at times, but a lot of fun.

Dr. Grolmes: I would offer a slightly different perspective to augment the above valid comments. First of all, we had spent together quite a few years at Argonne. It was a great place to learn how to carry out good applied science and engineering research that would stand up to peer review. This was the fun part. Second, after the program that we were working on (the liquid metal fast breeder reactor or LMFBR) was canceled by President Jimmy Carter, the fun sort of went out of the work at the Lab. Then along came the opportunity to do some interesting work in chemical engineering space. So when I reflect on the question with 30 years hindsight, the decision to leave should have been obvious. That said, at the time there were plenty of unanswered questions, but we had the knowledge, the good work ethic, and some very good luck.

Q: What fundamental values come to mind when you think of safety?

A:

Dr. Henry: I guess from my perspective, just very simply, people think of this area as being a highly technical area but the fundamental value that you have is you have to understand the technology. You can’t just be a practitioner you have to really understand what it means to use it effectively. Then, people understand why certain things are things you don’t have to worry about and why other things you have to worry a lot about. If you are just a practitioner, you can’t separate out the two.

Dr. Fauske: In a similar way, you know, having the opportunity to make the workplace safe, you feel good about it. Some of the work we are involved in, we are talking about saving lives.

Dr. Henry: We are also helping our clients protect their investment.

Dr. Fauske: Yes, that’s important.

Dr. Henry: I am sure Hans feels this way about all the things they have developed on the chemical side and I certainly feel this way about Modular Accident Analysis Program (MAAP) itself - is its in essence a textbook that’s teaching people what the technology is all about. And the documentation is there for you to read and understand it; including the experiments behind the technology. The same is true of the VSP, the RSST, ARSST etc. These are tremendous tools that enable the user to know their own system and understand what the fundamental safety issues are.

Q: Tell us some of the most significant ways that you have seen the industry change over the last 35 years.

A:

Dr. Fauske: Unfortunately, significant changes take place only following catastrophic incidents like Three Mile Island which happened in 1979, the BHOPAL incident which happened in 1984, that’s roughly 30 years ago, and which killed several thousand people in India, the Chernobyl incident in 1986 and the Fukushima incident in 2011. After such incidents, generally there is a real push in the industry for a time to improve safety in whatever way it takes but it really takes these big incidents for it to happen. Having said all that, as a result the industry has become safer but there is still work to be done.

Dr. Henry: Along those lines, one of the key things that we were involved with on the nuclear side was putting together the first set of Severe Accident Management Guidelines (SAMGs). This is the first time the industry pushed its way beyond what the operators are trained to do by procedures. So there was an understanding of what could happen if things went beyond their procedures. Now they have this integrated technology reference book that the operators can go to in an accident, or they can write their own general guidelines, saying ‘if we get this far and things look like this, here’s what we should do.' This makes the plants a lot safer.

Q: What do you see as the biggest change for the near future of process safety based on what you have seen so far to date?

Dr. Fauske: The biggest change that I would like to see is basically making process safety a number one priority, even before profit. That’s a tough one, but I think it’s needed. I talk to a lot of people, customers and so on, and they say, ‘you well know the upper management isn’t willing to spend the money, it’s too costly.’ But it really comes down to a safety culture. You need to have a safety culture in a company, and you need to practice it, not now and then, but all the time. And particularly it has to come from up above, the president, the chairman or whoever is the top guy. It’s very important. And, I think if you are going to improve the industry from a safety point of view that’s got to take place. And in some companies, that is the case. You may have a good company doing all the right things and you never really have a serious incident. But if you have another company that has a big one, that affects everybody, and that’s important.

Dr. Henry: I’m not quite sure where to even start on this but it is extremely important. I can’t tell you how many times in discussions of all these types of possible accident conditions that we have to take care of or to at least address or think through that the subject has come up ‘well that’s never happened.’ And, a lot of people fall into the trap that if it hasn’t happened before then it isn’t going to happen.

Most of the time we are dealing with things that are very low probability, but they still happen and, sometimes the consequences are considerable, just like Chernobyl. But the other side of the coin, if you’re going to have a safety culture, when the problem is solved you say it’s solved. You don’t just continue to milk it and let it hang on because all you are doing is diffusing the focus on the real activities that are needed. All of us think strongly that you don’t give up on a problem until its solved, but when a problem is solved, you don’t back away saying “this issue is solved”.

Dr. Fauske: Another thing, I think there is still a strong need for training courses in safety. In that regard, to take even more advantage of some of the incidents that have happened. What do you do to prevent another incident? That’s an important topic. I don’t think it gets enough emphasis, but that’s an area that certainly we can support.

Q: What are you most proud of in your years of professional achievements?

A:

Dr. Fauske: You may be surprised when I say this but every question you’re talking about except for maybe one, relates to safety, and our work relates to safety, and so the thing I think we are most proud of, well myself, I am sure Bob too will agree with this, is that we have basically been responsible for ensuring a safe work place – I am talking about FAI now, since 1993 up to now. If you make that subtraction that’s 21 years where we have not had a lost work day due to incident. That’s quite an accomplishment. I think we take it very seriously. It’s a hell of a record. The other more obvious one, I think it’s fair to say that Bob, Mike, myself and other people in this company, we established a reputation as being a world leader in process safety, both nuclear and chemical, a fact nobody would question.

Dr. Henry: I am going to be very specific about what I am most proud of. It’s a very short list but it encompasses a lot things. The thing I am most proud of is the fact that we have created these jobs for all these very fine people that surround us every day. Of course, we didn’t do it by ourselves, but we did have the initial idea to go do it and we’ve had such talented people here. It has been a joy to come to work every day and the fact that you can just go down the list of people we have and see how long they have been with us, I am extremely proud of it. It’s not often that you go out and start a company where you aren’t sending work overseas, you are selling overseas.

Secondly, it goes along with what Hans says about being world leaders. I’m just very proud of what we have done both on the nuclear side and chemical side, developing products that are used on a daily basis by these major companies: chemical companies in the United States, utility companies in the United States, MAAP specifically is used in numerous companies now that are in just about all the nuclear countries of the world.

Dr. Fauske: On the chemical side, we are everywhere. If no one knew any better they would think we were a company with thousands of people working here.

Stepping down from the FAI leadership role 3 years ago (I am still a full-time employee), we are proud of the current leadership team. During their leadership the business has increased nearly threefold and is still growing, which gives us confidence that the company is clearly in good hands.

Dr Henry: We always thought of FAI like a family and we are very proud to be contributing a highly productive organization to the Westinghouse corporate portfolio.

Dr. Fauske: The other thing that’s enjoyable, particularly to Bob, Mike and me, is that we’ve been working together since 1964. At times we didn’t necessarily agree on everything, but we have always had a wonderful relationship.

Dr. Henry: Hans was my thesis advisor when I came to Argonne to do my Ph.D. thesis. I was his first graduate student.

Dr. Fauske: Not only that, but for Bob’s son Chris (who also works here), I was also his advisor for his Ph.D., which is kind of unique. I get a kick out of it, father and son.

Dr. Henry: Let me just add that Mike Grolmes was one of the first classmates I met at Notre Dame the first day of freshman year and we went all the way through graduate school together. We came to Argonne to write our theses and we were office mates in an office that was right next to Hans’ office.

Dr. Fauske: I wasn’t Mike’s Ph.D. thesis advisor, but I enjoyed discussing with him the progress in his research work.

Dr. Grolmes: I left the FAI organization at the end of 1992, so I have been out of the FAI picture for about 20 years. The organization now is vastly different from the early years. This is as it should be if an organization and a concept are to survive. The FAI organization now is well and firmly established in the industries that are being served. The leadership position is widely acknowledged. All of the excellent company developments in the last 20 plus years have been a result of the dedication, conviction and leadership of Hans and Bob.

As for myself, I can be proud that I was able to (for a time) establish an independent presence in the chemical safety business. However, the real story here is the lifelong good relations with Hans and Bob. When the time came and circumstances changed for me, Hans did not hesitate to offer shelter. So I am very proud to be once again associated with the company that long ago I was a part of its birth on the scene. But again, the fact that there is a substantial company to return to is the remarkable accomplishment of Hans and Bob.

Here's to the next 35. Learning something everyday and teaching others certainly makes being "Penny" exciting. ;) Let us know if we can help you.