Q&A On PHA: Who, What, Where, When & Why of Process Hazards Analysis

Why perform a risk analysis?

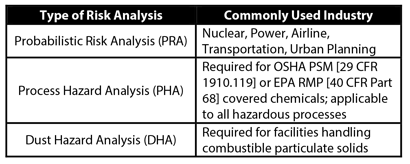

Risk Analysis goes by many names and many acronyms. While the techniques differ by industry or application (see Tables 1 and 2), all are set to accomplish the same goal: to identify hazards within a process. Some industries have regulatory requirements to perform risk assessments. Others are prompted by insurers or another Authority Having Jurisdiction (AHJ) or have been initiated by internal corporate objectives.

The results of a risk analysis can be used to justify process improvements. Additionally, identifying and mitigating hazardous scenarios through risk analysis is considered a Recognized and Generally Accepted Good Engineering Practice (RAGAGEP), and ultimately makes good business sense. Continue on to read about one of the many forms of risk assessment.

What is a Process Hazard Analysis (PHA)?

A Process Hazard Analysis (PHA) is a rigorous and systematic approach to identifying, evaluating, and controlling the hazards of processes involving highly hazardous chemicals.[1] Consequences addressed can include employee safety, environmental impact, public safety, extent of equipment/facility damage, and/or effects on public image. Causes of such situations are identified, and the scenarios are ranked on severity as well as frequency of occurring.

Safeguards currently in place are accounted for, and where risk is unmitigated/deemed unacceptable, recommendations for follow up actions are provided. A management review is later conducted to determine what changes will be made. The end goal of performing a PHA is not to label a process as “safe”, but to detect unprotected situations and trigger the necessary safety improvements to reduce or minimize risk.

When should a PHA be conducted?

A risk analysis for hazardous processes should be conducted for each stage of design, operation, and shut down. [2] PHAs are required to be completed initially and revalidated every five years – however, major changes made to a process warrant a total re-do to be conducted earlier.[1] Furthermore, when either temporary or permanent modifications are made to a hazardous process, a Management of Change (MOC) PHA should be utilized to evaluate the inherent hazards that can result from the change. Table 2 shows the applicability of several PHA techniques during some of the different phases of a process lifecycle.

![Table 2 – Applicability of Select PHA Techniques[2]* Table 2 – Applicability of Select PHA Techniques[2]*](https://www.fauske.com/hs-fs/hubfs/UM%20table%202.png?width=363&name=UM%20table%202.png)

*A PHA leader will determine the most appropriate methodology

Serious safety incidents continue to occur at an alarming frequency across all industries and during all stages of operation (see Figures 1 a, b, and c for brief case studies). Awareness and unwavering attention to details are essential to avoiding serious incidents. That being said, a risk analysis is only as good as the team assembled to conduct it.

![Figure 1a. – NASA Apollo 1 Ground Fire[3] Figure 1a. – NASA Apollo 1 Ground Fire[3]](https://www.fauske.com/hs-fs/hubfs/Apollo%201a.png?width=500&height=180&name=Apollo%201a.png)

![Figure 1b. – T2 Laboratories, Inc. Runaway Reaction and Explosion[4] Figure 1b. – T2 Laboratories, Inc. Runaway Reaction and Explosion[4]](https://www.fauske.com/hs-fs/hubfs/T2%20Labs-02.png?width=500&height=198&name=T2%20Labs-02.png)

![Figure 1c. – William Olefins, Inc. Explosion and Fire[5] Figure 1c. – William Olefins, Inc. Explosion and Fire[5]](https://www.fauske.com/hs-fs/hubfs/Olefins%20Explosion.png?width=500&height=180&name=Olefins%20Explosion.png)

Who should be involved in a PHA?

OSHA requires a PHA team to consist at a minimum of a process engineer, an operator, and a facilitator (leader). In order to effectively identify safety consequences, persons knowledgeable of the process and the hazards associated with it must participate in the analysis.[1] FAI engineers are subject matter experts in reactive chemistry, flammability, combustible dust, electrostatics/electrical hazards, as well as other process safety hazards, and are available to facilitate (lead) and/or participate as specialists on teams conducting risk analysis.

In addition to hazard scenario identification, FAI offers the complete package to understanding the hazards of a process including material hazard characterization, operational condition testing, determination of mitigation design parameters, calculation of emergency relief systems sizing, and chemical release dispersion analysis. Contact us for all of your process safety needs.

For more information on risk analysis, PHAs, or any of the topics mentioned in this article, email info@fauske.com or call 877-328-7531.

References

1. "Process Safety Management." Occupational Safety and Health

Administration. United States Department of Labor, 2000. Web.

2. "Process Hazard Analysis (PHA)." Chemical Emergency Prevention & Planning (July-Aug. 2008. US EPA Region 10. Web.

3. "Apollo 1." Wikipedia. Wikimedia Foundation, 16 Apr. 2017. Web.

4. T2 Laboratories, Inc. Runaway Reaction. Rep. no. 2008-3-I-FL. U.S. Chemical Safety and Hazard Investigation Board, Sept. 2009. Web.

5. Williams Geismar Olefins Plant. Rep. no. 2013-03-I-LA. U.S. Chemical Safety and Hazard Investigation Board, Oct. 2016. Web.