The Role Or Hazardous Area Classification In Process Safety

Electrical and electronic equipment such as motors, generators, transformers, circuit breakers, fuses, switches, relays, solenoids and resistors produce significant amounts of heat, arcing and sparking during normal and abnormal operation, which could pose a substantial risk of fire or explosion in facilities where chemicals are manufactured, processed or utilized. To minimize the risk of fires or explosions that could result from this arcing, sparking and heat dissipation, it is critically important that electrical/ electronic equipment be designed, tested and labeled as being acceptable for use in the areas in which they are installed. This holds especially true for hazardous (classified) locations, i.e. locations where flammable, combustible or ignitable gases, vapors, liquids, dust, fibers or flyings may be present.

Hazardous area classification is the evaluation and classification of hazardous (classified) locations using scientific and engineering principles, within facilities where chemicals are manufactured, processed or utilized. Hazardous areas are classified solely for the purpose of ensuring the safe and proper specification and installation of electrical/ electronic equipment located within them.

A hazardous area classification is typically shown on plan view drawings of the facility (and sometimes on elevation drawings) that are commonly referred to as area classification drawings/diagrams. Based upon the area classification drawings, electrical/ electronic equipment can be properly specified and installed such that the risk of fires or explosions is greatly reduced.

Hazardous (Classified) Locations

Article 500 of the National Electrical Code (NEC) (reference 1) defines the requirements for the safe and proper specification and installation of electrical/electronic equipment in hazardous (classified) locations. NEC Article 500.5 (A) states that "Locations shall be classified depending on the properties of the flammable gas, flammable liquid-produced vapors, combustible liquid-produced vapors, combustible dust or fibers/flyings that may be present, and the likelihood that a flammable or combustible concentration or quantity is present. Each room, section, or area shall be considered individually in determining its classification."

Hazardous Area Classification

Each room, section and area within a facility where chemicals are processed or utilized are evaluated individually and assigned a Class I, II or III, Division 1 or 2, Group A, B, C, D, E, F or G classification based on several criteria: (1) the types of chemicals that are present; (2) the probability of their presence during normal and abnormal operation; (3) the volume being processed or utilized; and (4) the physical properties (concentrations, densities, pressures, temperatures and flows) that are observed during normal and abnormal plant operating conditions.

Class I Locations

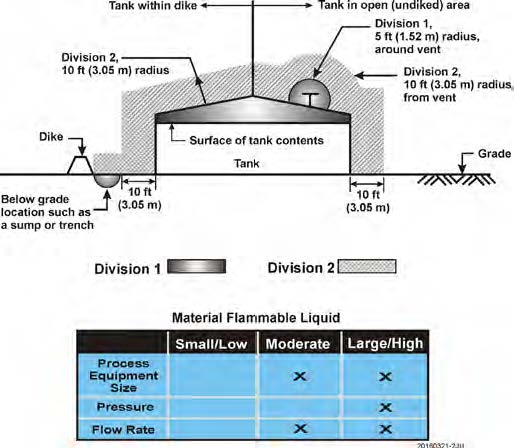

A Class I location is a location where fire or explosion hazards may exist due to flammable gases, vapors or flammable liquids. NFPA 497 (reference 2) provides recommended practice for the classification of Class I hazardous (classified) locations. NEC Articles 500 and 501 define the requirements for the safe and proper specification and installation of electrical/electronic equipment in Class I locations. NFPA 497 and NEC Articles 500 and 501 are relied upon heavily when performing area classifications and when specifying electrical/electronic equipment for safe and proper installation in Class I locations. Figure 1 (below) is an example of an area classification diagram for a Class I area.

Figure 1 - Area Classification Diagram for a Class I Area (Flammable Liquid)

Class I Division 1

A Class I, Division 1 location is a location in which ignitable concentrations of flammable gases, flammable liquid-produced vapors, or combustible liquid-produced vapors may exist under normal operating conditions.

Class I Division 2

A Class I, Division 2 location is a location in which ignitable concentrations of flammable gases, flammable liquid-produced vapors, or combustible liquid-produced vapors may exist under abnormal operating conditions.

Class I Group Designations

Class I flammable gases, vapors and liquids are grouped into one of four (4) groups (Groups A, B, C or D) based on their physical properties and the ease in which they can be ignited. Table 4.4.2 in NFPA 497 (reference 2) shows the physical properties and Group classifications of many commonly used flammable gases, vapors and liquids. Acetylene is an example of a Group A flammable gas. Hydrogen is an example of a Group B flammable gas. Carbon Monoxide is an example of a Group C flammable gas. Gasoline is an example of a Group D flammable liquid.

Class II Locations

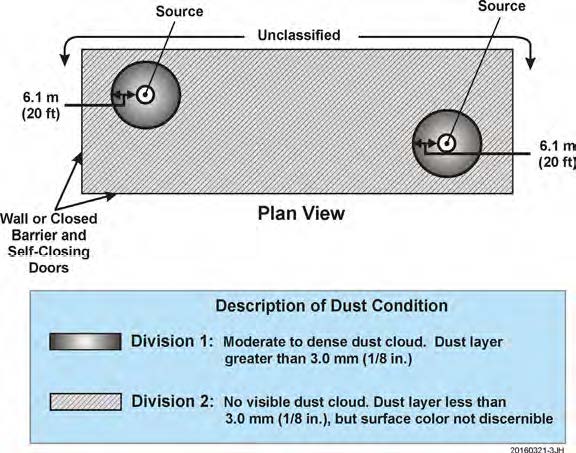

A Class II location is a location where fire or explosion hazards may exist due to combustible dust. NFPA 499 (reference 3) provides recommended practice for the classification of Class II hazardous (classified) locations. NEC Articles 500 and 502 define the requirements for the safe and proper specification and installation of electrical/electronic equipment in Class II locations. NFPA 499 and NEC Articles 500 and 502 are relied upon heavily when performing area classifications and when specifying electrical/electronic equipment for safe and proper installation in Class II locations. Figure 2 (below) is an example of an area classification diagram for a Class II area.

Figure 2 - Area Classification Diagram for a Class II Area (Combustible Dust)

Class II Division 1

A Class II, Division 1 location is a location in which combustible dust is in the air under normal operating conditions in quantities sufficient to produce explosive or ignitable mixtures, or where accumulations on electrical equipment are sufficient to interfere with the safe dissipation of heat generated by the equipment.

Class II Division 2

A Class II, Division 2 location is a location in which combustible dust due to abnormal operating conditions may be present in the air in quantities sufficient to produce explosive or ignitable mixtures, or where accumulations on electrical equipment may be sufficient to interfere with the safe dissipation of heat generated by the equipment.

Class II Group Designations

Class II combustible dusts are grouped into one of three (3) groups (Groups E, F or G) based on their physical properties and the ease in which they can be ignited. Table 5.2.2 in NFPA 499 (reference 3) shows the physical properties and Group classifications of many commonly used combustible dusts. Titanium is an example of a Group E combustible dust. Carbon Black is an example of a Group F combustible dust. Nylon Polymer is an example of a Group G combustible dust.

Class III Locations

A Class III location is a location where fire or explosion hazards may exist due to ignitable fibers or flyings. NEC Articles 500 and 503 define the requirements for the safe and proper specification and installation of electrical/electronic equipment in Class III locations.

Non-hazardous (Unclassified) Locations

Any area which cannot be classified as a Class I, II or III hazardous (classified) location is considered to be an unclassified or non-hazardous area.

Conclusion

Electrical and electronic equipment such as motors, generators, transformers, circuit breakers, fuses, switches, relays, solenoids and resistors produce significant amounts of heat, arcing and sparking during normal and abnormal operation, which could pose a substantial risk of fire or explosion in facilities where chemicals are manufactured, processed or utilized. To minimize the risk of fires or explosions that could result from this arcing, sparking and heat dissipation in hazardous (classified) locations, it is critically important that electrical/electronic equipment be designed, tested and labeled as being acceptable for use in the areas in which they are installed.

Hazardous area classification drawings provide a road map that ensures that electrical/electronic equipment can be safely and properly specified and installed in hazardous (classified) locations such that the risk of fires or explosions is greatly reduced. Work with a qualified engineering testing lab that has the expertise, experience and capabilities necessary to perform accurate and practical area classifications for hazardous (classified) locations within any process facility.