Do you know how to conduct cost effective, precise and comprehensive process safety or thermal hazards testing and consulting when needed? What are your process safety management (PSM) standards when it comes to thermal hazards?

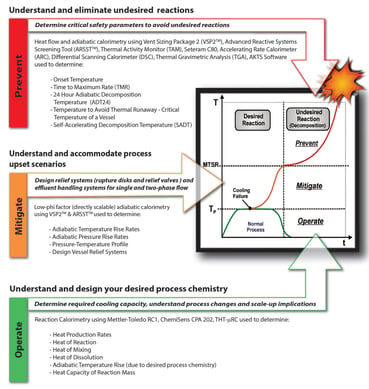

Let's focus on a 3-step process:

1. Prevent - Understand and eliminate undesired reactions

2. Mitigate - Understand and accommodate process upset scenarios

3. Operate - Understand and design your desired process chemistry

Prevent

Prevent

First, in understanding and eliminating undesired reactions, determine critical safety parameters to avoid undesired reactions. Heat flow and adiabatic calorimetry can be determined by using lab equipment such as Vent Sizing Package 2 (VSP2 TM), Advanced Reactive Systems Screening Tool (ARSST TM), Advanced Reactive Systems Screening Tool (ARSST TM), Thermal Activity Monitor (TAM), Seteram C80, Accelerating Rate Calorimeter (ARC), Differential Scanning Calorimeter (DSC), Thermal Gravimetric Analysis (TGA), AKTS Software as key tools. These tests can determine:

- Onset Temperature

- Time to Maximum Rate (TMR)

- 24 Hour Adiabatic Decomposition Temperature (ADT24)

Mitigate

Design relief systems (rupture disks and relief valves) and effluent handling systems for single and two-phase flow. Low-phi factor (directly scalable) adiabatic calorimetry using VSP2 TM and ARSST TM used to determine:

- Adiabatic Temperature Rise Rates

- Adiabatic Pressure Rise Rates

- Pressure-Temperature Profile

- Design Vessel Relief Systems

Operate

Reaction Calorimetry using Mettler-Toledo RC1, ChemiSens CPA 202, THT-uRC used to determine:

- Heat of Production Rates

- Heat of Reaction

- Heat of Mixing

- Heat of Dissolution

- Adiabatic Temperature Rise (due to desired process chemistry)

- Heat Capacity of Reaction Mass

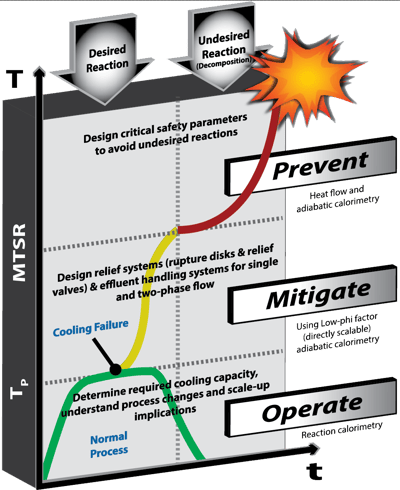

Here's another look in a graphic:

If you enjoyed learning about thermal hazards testing, check out our case study on low thermal inertia adiabatic calorimetry. In this case study, FAI performs tests to determine what is the self accelerating decomposition temperature of a 50 kg package of azodicarbonamide. Download the case study now to to learn more about AKTS software, self accelerating decomposition temperature, the United States SADT test, and much more.