Vent Sizing, Relief System Design, Reactive Chemistry and Role of Two-Phase Flow

Unlike other emergency vent sizing courses, this curriculum highlights simplified calculation methods capable of giving safe - but not overly conservative - relief system designs, with an emphasis on reactive chemistries and the role of two-phase flow. The course will be provided October 16-18 at the Burr Ridge (Chicago) Headquarters of Fauske & Associates (FAI).

Benchmarking of these methods will be illustrated with incidents and available plant data. Utilization of methods and equations will be demonstrated through practical design examples, covering vapor, gassy and hybrid systems.

Benchmarking of these methods will be illustrated with incidents and available plant data. Utilization of methods and equations will be demonstrated through practical design examples, covering vapor, gassy and hybrid systems.

Attendees will participate in group workshops and complete an independent quiz at the end of the course in order to ensure comprehension of the material. A laboratory session demonstrating experimental techniques will be held the afternoon of October 18, but is optional.

FAI is accredited through International Association for Continuing Education and Training (IACET)and FAI University course attendees are awarded CEUs upon meeting all the necessary requirements. FAI University offers a wide array of training courses globally to augment our customized testing, engineering and consulting services.

Course Topics - Day 1

- Introduction to Vent Sizing and Case Study

- Vent Sizing Fundamentals

- Codes and Standards Explanation

- History of DIERS

- Two-Phase Flow Considerations

- Experimental Considerations

- Vent Sizing Based on All Gas or Vapor Venting

Course Topics - Day 2

- Vapor System Vent Sizing

- Gassy System Vent Sizing

- Hybrid System Vent Sizing

- Simplified Two-Phase Flow Methods for

- Vapor, Hybrid, and Gassy Systems

- Non-Reactive Fire Sizing

Course Topics - Day 3

- Stable Relief Valve Operation

- Discharge Coefficient Evaluation

- Containment and Disposal Considerations

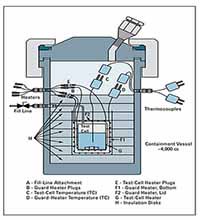

- Lab Demonstrations (optional)

Learning Outcomes

- Understand up-to-date DIERS vent sizing methodologies and models, as well as the role of single and two-phase flow in venting behavior

- Perform vent sizing calculations using the correct models and methodologies

- Apply adiabatic calorimetry data

- Be able to use hands-on techniques and “rules of thumb” to ensure that realistic vessel and vent size conditions are specified