James Burelbach, PhD, Process Safety & Business Development Leader, Fauske & Associates

The Advanced Reactive System Screening ToolTM (ARSST) is a popular low thermal-inertia safety calorimeter. It is commonly used to quickly obtain directly scalable data on chemical reactivity hazards and thermally unstable substances. The ARSST provides reliable adiabatic data which can be used for a variety of safety applications including emergency relief system design DIERS vent sizing, studies of material compatibility or thermal stability, and sometimes just to better understand the unintended (or intended) reaction chemistry. ARSST data include adiabatic rates of temperature and pressure rise (dT/dt and dP/dt) during a runaway chemical reaction which can be directly applied during process scale-up to size pressure relief vents and quench or knockout tanks and to underpin other aspects of process safety management. Developed by Fauske & Associates (FAI) the ARSST has options for customization such as a high-pressure vessel and flow regime detector.

The ARSST is based on DIERS technology which is recognized by OSHA as an example of good engineering practice. This easy-to-use device is an excellent tool for industry as well as any university engineering lab for research or unit operation studies (a SACHE module was developed for ARSST education).

ARSST tests are routinely used to model such diverse upset scenarios as loss of cooling, loss of stirring, mischarge of reagents, mass-loaded upset, batch contamination and fire exposure heating.

Such low thermal inertia adiabatic calorimetry data are essential for mitigation of chemical reactivity hazards.

The ARSST typically uses a relatively small yet representative sample size of 5-10 grams in a lightweight glass test cell with a volume of approximately 10 ml. Test cell volumes of 5 ml or 20 ml are sometimes used. The test cell is outfitted with a belt heater and then installed in a 350 ml (or 450 ml) pressure containment vessel. ARSST tests are typically run using open test cell methodology. In the open test configuration, the test cell is open to the containment vessel and boiling of the test sample is prevented by imposing an inert gas backpressure within the containment vessel.

But when does it make sense to Use the ARSST for Closed Cell Testing?

We are sometimes asked this question by customers who wish to get the most out of their ARSST apparatus. Closed cell testing is an ARSST innovation that has been available for several years, although it is not as commonly used as open cell testing. Some reasons to consider closed cell ARSST testing are:

- Directly scalable data are still possible if using thin wall glass

- Heavier test cells (ARC bombs or thick wall glass) can be used for thermal hazards screening

- Direct measurement of sample temperature in solids or liquids

- Magnetically stirring is still good

- Can directly measure vapor pressure of the reacting system

- Can utilize manual pressure balancing (to a point). Initially imposed external pressure can make active pressure balancing unnecessary even for a thin wall test cell.

- Better resolution of pressure for mild reactions (though not desirable for gas-generating systems)

- Onset detection for gas generating materials (pressure sensitivity is often better than temperature sensitivity)

- Use either low or high thermal inertia test cells (low or high phi factor)

- We recommend dedicated 450 ml containment vessel configured for closed cell operation

Below are some illustrations and examples from work we have done using the closed cell ARSST. We hope this information is of interest to ARSST users who look for innovative ways to get the most use out of their ARSST.

20 ml 10 ml 5 ml

“Long Neck” low φ ARSST Cells

“Long Neck” low φ ARSST Cells

Closed Cell ARSST Insulation Options

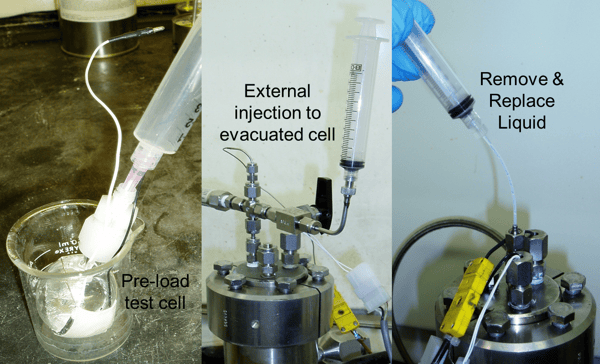

Closed Cell ARSST: Sample Addition

Closed Cell ARSST: Pressure Balancing

.jpg?width=350&name=Closed_Cell_ARSST_Pressure_Balancing_Automatic_(VSP).jpg)

.jpg?width=350&name=Closed_Cell_ARSST_Pressure_Balancing_Manual_(JPB).jpg) Automatic (VSP) Manual (JPB)

Automatic (VSP) Manual (JPB)

Examples of Closed Cell ARSST Data:

- 25% Vazo 67 in toluene

- Luperox 531 M80

- Vapor pressure (P-T data)

- Butyl Acrylate - Fire exposure

- 0.5% AIBN in Butyl Acrylate: Induction time

- 25% di-t amyl peroxide in pentadecane

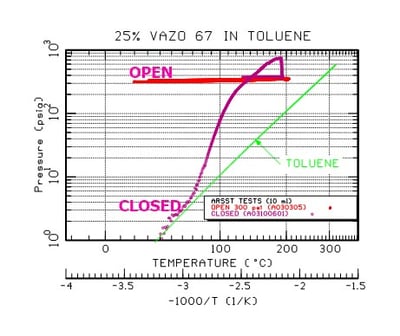

Example 1. ARSST Closed (vac) vs. Open (300 psi)

_vs_open1.jpg?width=400&name=ARSST%20=_Closed_(vac)_vs_open1.jpg)

- 9 g 25% Vazo 67 in Toluene (too much)

- Closed 10 ml “long neck” glass test cell

- Heat at 2°C/min, external 300 psi pressure, rupture at 190°C (see also DIERS Spring 2006 LV)

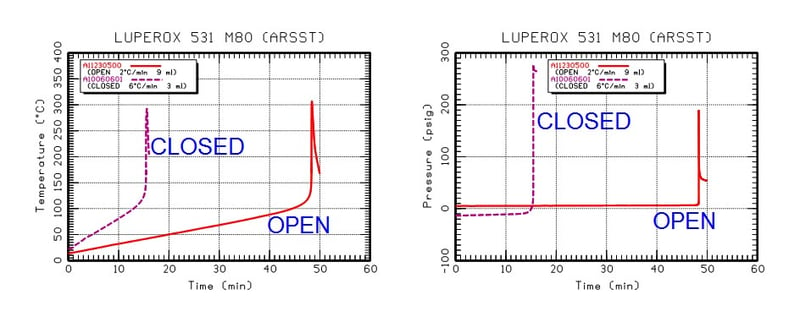

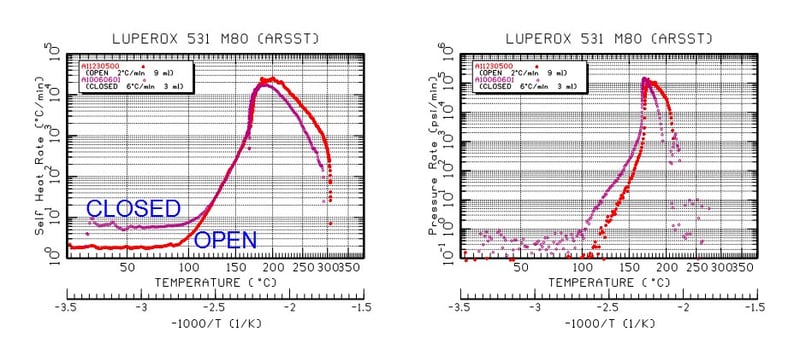

Example 2. ARSST Screening for Energetic Decomposition

- Used “saved” 2°C/min calibration polynomial

- 9 ml sample (open 10 ml cell) scans at 2°C/min

- 3 ml sample (closed 5 ml cell) scans at 6°C/min

- => Both cases shatter test cell

Example 2. Open and Closed Cell ARSST

- Rapid closed cell screening (6C/min) for decomposition and comparison to standard (2C/min) open cell test

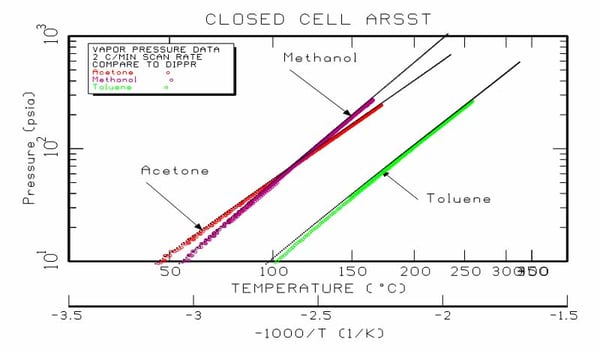

Example 3. P-T Data

- Used half-full test cells (closed)

- Started at vacuum, but with external pressure

- Heat at 2°C/min (PID mode)

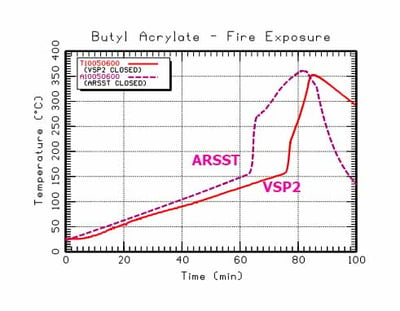

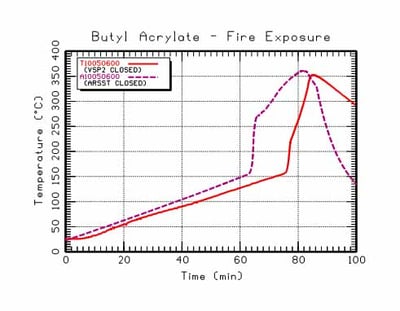

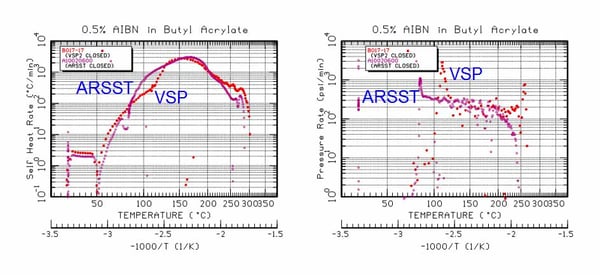

Example 4. Closed cell BA tests in ARSSTTM & VSP2TM

- Fire exposure ARSST simulation and comparison to VSP2 test

- ARSST test (uninhibited BA, 10 g in 20 ml cell) started at 1 atm N2

- Developed pressure leak (into cell) late after exotherm

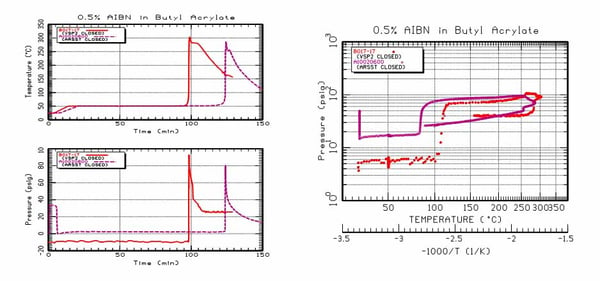

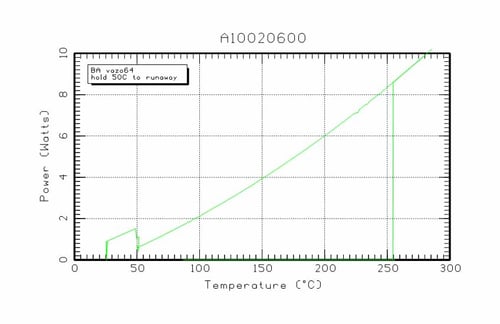

Example 5. Closed cell AIBN/BA Induction Tests

- Adiabatic hold (induction) tests on butyl acrylate with 0.5% AIBN

- ARSST (9.9g in 20 ml cell) started with 1 atm N2 pressure

- Heater power “dialed back” when sample reached target 50°C

2°C/min heater calibration → 0°C/min calibration

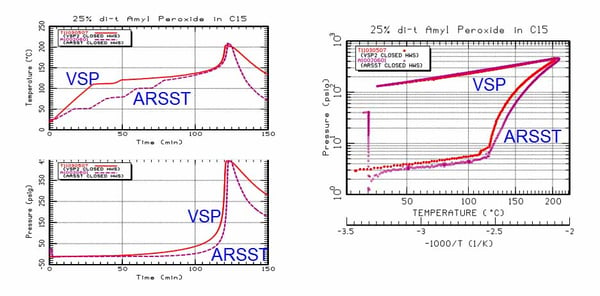

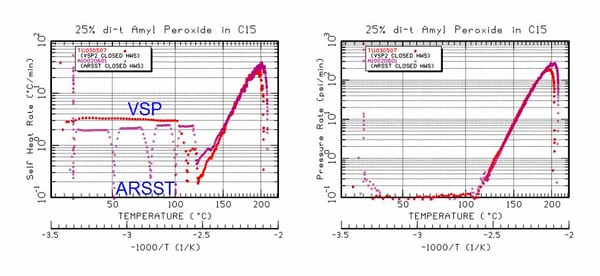

Example 6. Closed cell tests in ARSST & VSP2

Example 6. Closed cell tests in ARSST & VSP2

- 25% di-t amyl peroxide in pentadecane

- ARSST test (8.8 g in 20 ml cell) starts at vacuum, has series of adiabatic hold steps, heater power tuned at 50, 80, 100C

If you are interested in more information on ARSST, dig deeper with out white paper on quick hazard screen by closed cell ARSST using standard ARC bombs below.