Non/Equilibrium Flashing Flows in Safety Relief Valves (SRVs)

Further Clarification of Non-Equilibrium and Equilibrium Flashing Flows Through Top Located Safety Relief Valves (SRVs)

By: Hans K. Fauske, D.Sc., Regent Advisor, Fauske & Associates

Non-Equilibrium Flashing Flow

If all liquid exist at the stagnation condition (no vapor), extensive data suggest that a simple length criterion of the order of 100 mm characterizes the residence time (~ of the order of 1 ms) requirement for approaching equilibrium flashing flows which are well described by the Equilibrium Rate Model (ERM) (Fauske, 1985)

![]() (1)

(1)

where ![]() is the latent heat of evaporation, vfg is the change in liquid-vapor specific volume, T is the temperature and C is the liquid specific heat, all evaluated at stagnation condition. In contrast, the maximum non-equilibrium mass flux as the length approaches zero is given by

is the latent heat of evaporation, vfg is the change in liquid-vapor specific volume, T is the temperature and C is the liquid specific heat, all evaluated at stagnation condition. In contrast, the maximum non-equilibrium mass flux as the length approaches zero is given by

![]() (2)

(2)

where P is the stagnation gauge pressure and ρ is the liquid stagnation density. Considering that

Gmax >> GERM (3)

determines the relevant velocity and the length requirement of about 100 mm for all liquid stagnation condition (near saturated liquid and subcooling).

Equilibrium Flashing Flow

If liquid-vapor (void fraction > 0.1) exist at the stagnation condition, the length L (mm) required to satisfy a residence time of about 1 ms is given by

L (mm) = 1 (ms) g GERM/r (mm/ms) (4)

resulting in a length requirement much smaller than 100 mm. In other words 100 mm length requirement is only relevant to all liquid stagnation conditions.

Given the above observations, Eq. 1 can be used without modification to estimate flashing two-phase flows through top located SRVs for relief sizing purposes using the following equation (Fauske, 1999) if Eq. 4 and stagnation vapor void fraction a > 0.1 are satisfied

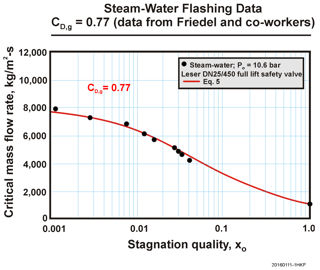

(5)

(5)

where xo is the stagnation quality, CDg is the valve manufacturer certified discharge coefficient for gas flow, and Gg is the gas flow (sonic or subsonic) through an ideal nozzle. An example of comparison with Eq. 5 and experimental data is illustrated below. In this case Eq. 4 suggests a length L of only about 10 mm to satisfy equilibrium flashing which is clearly satisfied by the SRV. Furthermore a stagnation quality of xo = 0.001 is equivalent to a = 0.14 at the 10.6 bar stagnation pressure.

Both requirements to satisfy equilibrium flashing flow are sensitive to the stagnation pressure. As an example consider a stagnation pressure of 62 bar, result in L = 40 mm and xo = 0.0048, which is consistent with experimental data (Sozzi and Sutherland, 1975.)

Both requirements to satisfy equilibrium flashing flow are sensitive to the stagnation pressure. As an example consider a stagnation pressure of 62 bar, result in L = 40 mm and xo = 0.0048, which is consistent with experimental data (Sozzi and Sutherland, 1975.)

References

Hans K. Fauske, 1985, "Flashing Flows Or: Some Practical Guidelines for Emergency Releases," Plant/Operations Progress, July, 1985.

Hans K. Fauske, 1999, "Determine Two-Phase Slows During Releases," Chemical Engineering progress, February, 1999.

Sozzi, G. L. and Sutherland, W. A., 1975, "Critical Flow of Saturated and Subcooled Water at High Pressure," Report NEDO-13418, General Electric Company, San Jose, CA (July).

For more information regarding this or other relief system design concerns, contact us at info@fauske.com, 630-323-8750