By: Ursula Malczewski, Chemical Engineer – Onsite Safety Services, Fauske & Associates, LLC

The Basics

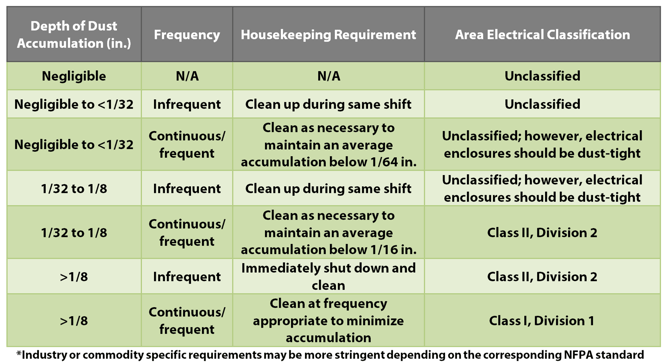

Having fugitive dust in a facility is literally like throwing money out of a process. Emissions from a system  waste the raw material costs and diminish both the quantity of product and potential revenue. Furthermore, it is a waste of resources (both time and money) for an employee or external company to be hired to clean the dust emissions. The finest, most hazardous material settles on hard to reach surfaces such as rafters, between drop ceilings, and on the tops of tall process equipment. In addition, equipment required to safely clean combustible dust can be expensive; and regular shop vacs cannot be used. If a hazardous quantity of explosible dust accumulates or can be suspended in air, it is required that equipment in the local area be properly rated and classified (Table 1). To convert or construct an area to be electrically classified can cost tens of thousands of dollars.

waste the raw material costs and diminish both the quantity of product and potential revenue. Furthermore, it is a waste of resources (both time and money) for an employee or external company to be hired to clean the dust emissions. The finest, most hazardous material settles on hard to reach surfaces such as rafters, between drop ceilings, and on the tops of tall process equipment. In addition, equipment required to safely clean combustible dust can be expensive; and regular shop vacs cannot be used. If a hazardous quantity of explosible dust accumulates or can be suspended in air, it is required that equipment in the local area be properly rated and classified (Table 1). To convert or construct an area to be electrically classified can cost tens of thousands of dollars.

NFPA 654 Guidance for Area Electrical Classification for General Combustible Dust* [1]

The Worst Case Scenarios

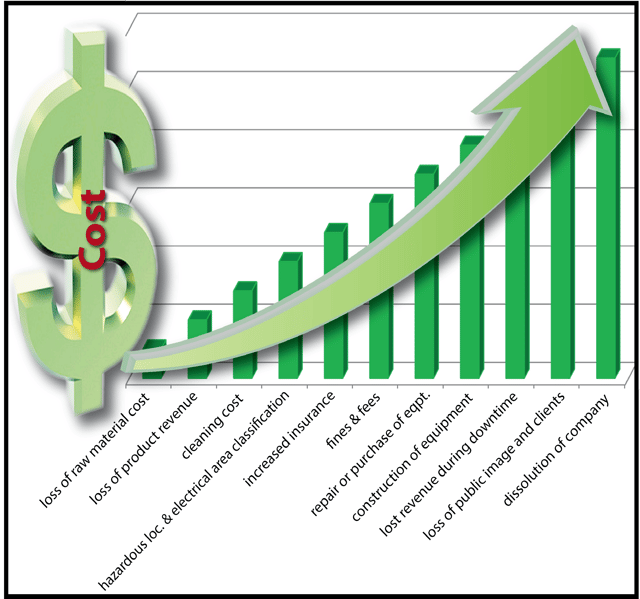

If fugitive dust isn’t addressed immediately, the costs of these emissions can be much greater. Under the adverse conditions, hazardous dust can cause fires or explosions leading to loss of life, loss of property, and loss of public favor. Fuel (fugitive hazardous dust) outside of process equipment results in a higher probability for secondary explosions to occur which can be more devastating and occur milliseconds after the initiating event. If the fire or deflagration does not cause complete closure of the facility, there may still be significant expenses: increased insurance premiums, lawyer bills, OSHA fines, repair or purchase of new equipment, construction of a new facility, etc. During this downtime, the line or whole plant will not be generating revenue and clients may be lost as they take their business elsewhere to meet their needs. Many times after such industrial disasters, companies can never recover. [2]

Figure 1: Increasing Costs of Fugitive Combustible Dust

The Solutions

There are two strategies to minimize fugitive dust emissions in a process: containment and collection. All components of enclosed systems that handle combustible particulate solids are required to be designed to prevent the escape of dust. If equipment cannot be designed for dust containment – as is the case, for example, for some pouring or transfer operations or open process equipment – a properly designed dust collection system with appropriate explosion protection would need to be installed. Another important factor is preventative maintenance. Preventative maintenance would preclude any issues if the source of emissions is a leak from faulty equipment. If the above methods are not enough to mitigate fugitive hazardous dust, housekeeping must be completed to meet thresholds and frequencies as specified in industry or commodity specific NFPA standards. [3]

Keep money in your pockets by keeping explosible dust contained in your process. If you have any questions regarding fugitive dust emissions in your facility or assessing your risk for combustible dust fires and explosions, don’t hesitate to contact us at DHA@fauske.com.

Images are used with permission from Hughes Environmental

Figure 2: Fugitive dust from cotton, iron, and paper industries on equipment and overhead ductwork

References

1. NFPA 654 (2017) Standard for the Prevention of Fire and Dust Explosions from the Manufacturing, Processing, and Handling of Combustible Particulate Solids, 2017 Edition. NFPA, Quincy, MA

2. Completed Investigations - Combustible Dust Explosions and Flash Fires. U.S. Chemical Safety Board. Web. , 2 Oct. 2016. <http://www.csb.gov/>.

3. NFPA 652 (2016) Standard on the Fundamentals of Combustible Dust, 2016 Edition. NFPA, Quincy, MA.

For a further discussion, please contact Ursula Malczewski malczewski@fauske.com 630-321-4784