In a recent issue of Safety & Health Magazine from the National Safety Council, author and speaker Bill Sims Jr. penned "Beyond Zero Injuries".

In a recent issue of Safety & Health Magazine from the National Safety Council, author and speaker Bill Sims Jr. penned "Beyond Zero Injuries".

In the article, Sims shares a story to illustrate how he differs from most experts who consider "Zero Injuries" the impervious goal of all work place safety programs. After one doubter challenged Sims he shared, " The BP Horizon rig ran for seven years with zero injuries and handed out safety awards one morning. That night, 11 men would die and CNN would report 390 maintenance items were neglected for repair on that rig. So how well did zero injuries work for BP?"

The point is made that zero at-risk behaviors are the goal - "from the management system and the workers in an interdependent culture where safety is never second to profits," states Sims. "Until leaders understand that there is a level of safety beyond zero, they will be stuck on the dreaded 'hockey stick plateau' in their safety performance".

He suggests every six-month safety meetings should include a pile of sticky notes. Ask employees "What's the next serious injury we will have? Where will it occur? What time of day?" Employees should then put their sticky notes on a wall grouped in clusters by where and when the injury will occur. "By finding the biggest clusters of sticky notes - that's probably where you next serious injury will occur," concludes Sims.

He suggests every six-month safety meetings should include a pile of sticky notes. Ask employees "What's the next serious injury we will have? Where will it occur? What time of day?" Employees should then put their sticky notes on a wall grouped in clusters by where and when the injury will occur. "By finding the biggest clusters of sticky notes - that's probably where you next serious injury will occur," concludes Sims.

I might add the "three-thoughts" rule. This is what I call the ability to think about someone three times over a short period of time and suddenly the phone rings... or, you know you need to call and check on that person - because inevitability, something's up. How many times do we perform an activity at work, whether its conducting a test, walking a certain path or carrying a piece of equipment and something occurs to us to make it better, or safer? If its more than once, say something. If its 3 times, say it loud!

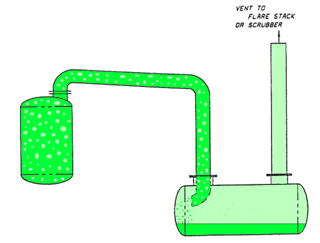

In the business of nuclear and chemical process safety engineering and testing, we constantly examine conditions and variables, setting and patterns - often, we advise and remind customers that with each variable change, your safety test has to change, too. Fine particulates in a combustible dust, for example, may test differently by batch and particle size. In sizing pressure relief devices for reactive chemicals, knockout tanks may not be sized correctly to accommodate effluent handling. Quantifying reaction rates and the resulting flow regime from an upset scenario is the first step. Then, relief devices and piping can be sized. Here, knockout tanks (used to separate liquid from vapor in a two-phase relief situation) are important and we notice that customers often use inadequately sized tanks for upset conditions - either by habit, assumptions or equipment limitation. (A knockout tank that is the same size as a reactor or storage tank is often incapable of effectively serving its purpose. As a rule of thumb for reactive upset scenarios, knockout tanks typically need to be 2 to 4 times the volume of the process vessel that is expected to relieve into it.) These are just some examples.

In the business of nuclear and chemical process safety engineering and testing, we constantly examine conditions and variables, setting and patterns - often, we advise and remind customers that with each variable change, your safety test has to change, too. Fine particulates in a combustible dust, for example, may test differently by batch and particle size. In sizing pressure relief devices for reactive chemicals, knockout tanks may not be sized correctly to accommodate effluent handling. Quantifying reaction rates and the resulting flow regime from an upset scenario is the first step. Then, relief devices and piping can be sized. Here, knockout tanks (used to separate liquid from vapor in a two-phase relief situation) are important and we notice that customers often use inadequately sized tanks for upset conditions - either by habit, assumptions or equipment limitation. (A knockout tank that is the same size as a reactor or storage tank is often incapable of effectively serving its purpose. As a rule of thumb for reactive upset scenarios, knockout tanks typically need to be 2 to 4 times the volume of the process vessel that is expected to relieve into it.) These are just some examples.

So, would you put sticky notes on your daily "habits", assumptions or equipment that cause you to pause 3 times in a short period? How would that look? Place sticky notes on your office or lab door as it occurs – a place of prominence for you and others? Write up a weekly summary or share in your weekly meeting?

As process safety engineers, we believe sticky note exercises in a group every six months is a great idea for many organizations. Frequency depending on variables such as staff and equipment changes can be increased.

Are you driving a beyond zero program? Learn how we can help.