By Harry J. Elston, Ph.D., CIH, consultant to Fauske & Associates, LLC

There are many organizations that are compliance-driven. They think that if they are compliant with OSHA regulations then their organizations are working safely. This thinking is not necessarily true.

"Corporate compliance with regulations does not equate to corporate safety."

Don’t misunderstand me. Compliance with regulations is important, but corporate compliance with regulations does not equate to corporate safety. I know of, and have worked for, a number of organizations that have been subjected to OSHA Compliance visits with the accompanying fines and they are naturally afraid of the cost for regulatory non-compliance. Likewise, I am also aware of corporations who view regulatory fines as a “cost of doing business.”

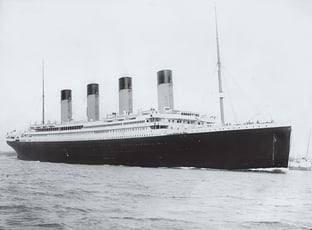

Let me provide a non-chemical example of how compliance does not equate to safety. The RMS Titanic was fully compliant with all applicable engineering and safety regulations at the time of her construction. And yet, she now lies silent at the bottom of the ocean. Compliance did not spare over 1500 passengers from their deaths.

Here are a couple of reasons why compliance does not equal safety:

• Regulations cannot keep pace with best practices: Technology will always outpace the regulatory landscape. For a concrete example of this, OSHA has yet to incorporate “inherently safer technology” (IST) into the Process Safety Management standard (29CFR1910.119) although IST is part of a 2014 report to the Obama Administration and the following Executive Order 13650. Regulations are changed through a lengthy political process and can stagnate, while best practices can be flexibly executed at the corporate level.

• Regulations generally focus on hazard, not risk: Hazard identification is generally pretty easy: Unguarded saws are easily spotted. However, an unguarded saw that is (1) dedicated to a single process by a written administrative control and high-level operator supervision and (2) has numerous jigs hanging next to it for those processes looks just like any other unguarded saw and may incur a “serious” –level OSHA violation, even though the risk may be sufficiently managed and the process may be deemed “safe” for the operator. From a laboratory-scale chemical safety perspective, hazards associated with reactive chemicals or reactive chemistry (highly exothermic processes), though very real, are simply not addressed by the Laboratory Standard. Risk is certainly not addressed by the Laboratory Standard.

Risk is the combination of the probability of a consequence occurring and the severity of that consequence. Risk is reduced by reducing the probability of an incident and/or reducing the severity. While hazard abatement is an important part of risk reduction, it is not the only part. Since regulatory compliance is often hazard-based, other important aspects of overall risk reduction can be missed or neglected, such as incorporating work practices to reduce injury severity as a result of an incident. An example would be including polycarbonate shielding in addition to a laboratory chemical hood for reactive chemical processes in order to prevent or reduce injury in the event of a run-away reaction.

I’ve seen far too many organizations that focus on compliance are still experiencing worker injuries that are costing them thousands per year in dollars and non-production. Moving to a risk-centric safety system often results in reduced workplace injury while simultaneously obtaining regulatory compliance.

Dr. Elston is a physical chemist and a Certified Industrial Hygienist and is the Principal and senior scientist at Midwest Chemical Safety, LLC. He is a consultant with Fauske & Associates, LLC. He can be contacted at helston@midwestchemsafety.com or 217-971-6047. For more information regarding Process Safety Management or Risk assessements, please contact Kris Fauske at 620-887-5224, kfauske@fauske.com.