What Should Your Nuclear Waste Management Technology (D&D) Include?

Does your nuclear engineering, testing and consulting firm provide technical expertise and program guidance for nuclear waste processing including the storage of chemical and defense waste and for process and safety analysis to support decontamination & decommissioning (D & D) of nuclear and hazardous material facilities?

Fauske & Associates, is a world leader in nuclear, industrial and chemical process safety. Founded in 1980 by Hans Fauske, D.Sc., Michael Grolmes, Ph.D. and Dr. Robert Henry, Ph.D., FAI became a wholly owned subsidiary of Westinghouse Electric Company, LLC, in 1986. FAI assumed early leadership roles in the acclaimed DIERS program for AIChE and the IDCOR program for the nuclear power industries. These activities led to state-of-the-art methodology and laboratory tools for characterizing chemical systems and computer models for analyzing severe accidents in commercial nuclear power plants used worldwide. Recognized worldwide for phenomenological modeling related to the prevention and accommodation of chemical and nuclear power accidents, FAI also provides advanced training and research in physics, chemical engineering, mechanical engineering, electrical engineering, nuclear engineering, computer science and other fields.

The FAI quality program includes NQA-1 conformance for Nuclear Safety Related projects, ISO-9001:2008/TickIT certifications for Computer Software development, and several ISO-17025 certifications. FAI is an Authorized Provider of IACET Continuing Education Units (CEUs).

FAI is also recognized for conducting comprehensive plant evaluations. FAI’s Nuclear Systems Group helps its customers enhance the availability and reliability of their operating plants while maintaining regulatory compliance, extending plant life and reducing operation and maintenance costs. With regard to industrial safety, FAI is a leader in the growing dust explosivity/combustibility and process safety areas. In addition to parts and laboratory testing, on-site consulting services are a key customer request for FAI.

Our three product areas for Nuclear Waste Technology D & D include:

|

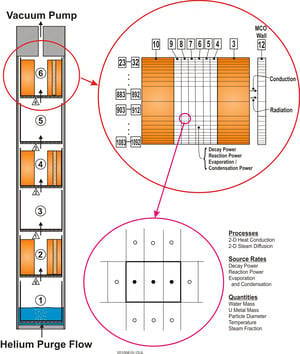

| Metallic spent nuclear fuel vacuum drying model |

Process & Safety Models & Analyses

• FATETM software for process and facility design and safety calculations

• Facility flow, heat transfer and toxic/radiological materials transport

• Predict thermal stability during waste processing, shipping and storage

• Manage flammable and explosive hazards

• Facility fire analysis including toxic/radiological effects

• Chemical reaction propagation limits, including pyrophoricity

• Flammable gas generation by chemical reactions and radiolysis

• Aerosol generation, transport, deposition and removal

• Facility emissions and source terms for processes, accidents and D & D

• Emergency preparedness

Experimental Facilities for Hazard Quantification

• Lab-scale equipment for measuring chemical reaction, heat-up and pressurization rates

• Fluid systems testing, including waterhammer and flow regime

• Chemical and thermal behavior during waste processing, shipping and storage

• Gas and vapor flammability limits

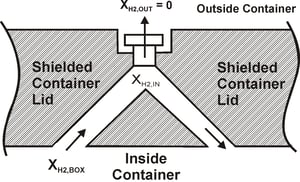

• Vent design validation for managing flammable gas (H2)

• Dust explosion and hybrid dust/gas systems

• Kinetics of decomposition and chemical reactions

Proven Quality Assured FATETM Software

• Provides a consistent framework for modeling a wide dynamic range of common Department of Energy (DOE) and commercial fuel and waste applications including:

- Treatment, and storage of defense waste, including metal fuel, fuel debris and sludge

- Drying of commercial oxide fuel

- Reactor building fire modeling or fire PRA

- Hydrogen release, transport and flammability for post-Fukushima vulnerability assessment

• FATE software predecessor code HANSF won a DOE innovation award (FY2000)

• FATE is developed and maintained under a NQA-1 Quality Assurance Program

|

| Innovative Solution for H2 Removal (double bore-hole arrangement with single filter) |

For more information regarding nuclear plant safety testing and waste management technology decommissioning and decontamination and other services, please contact feel free to contact us.