ABCs of Decommissioning Power Plants and Nuclear Waste Management

The NRC's Office of Nuclear Material Safety and Safeguards (NMSS) has project management responsibilities for 19 power reactors undergoing decommissioning. Locations of nuclear power reactors currently undergoing decommisioning are here: https://www.nrc.gov/info-finder/decommissioning/power-reactor/

According to the Nuclear Energy Institute's (NEI) "Fact Sheet on Decommissioning Nuclear Power Plants":

- Decommissioning is the process by which nuclear power plants are retired from service and terminate the operating licenses granted by the U.S. Nuclear Regulatory Commission. To ensure that decommissioning is safe and environmentally sound, the NRC established regulations and associated guidance outlining the requirements and process companies must follow. The NRC’s decommissioning process facilitates participation by state and local authorities at several points along the way.

- The process involves decontaminating the facility to reduce residual radioactivity, dismantling the structures, removing contaminated materials to appropriate disposal facilities, storing used nuclear fuel until it can be removed from the site for disposal or consolidated storage, and releasing the property for other uses. The owner remains accountable to the NRC until decommissioning has been completed and the agency has terminated its license.

- To prepare for eventual decommissioning of a nuclear power plant, the NRC requires the companies that operate them to provide assurance that funds will be available to decommission the facility. Generally, this funding assurance is provided through a trust fund that is projected to grow throughout the plant’s operating lifetime. Companies work with federal and state regulators to ensure that enough money will be available. Decommissioning trust funds are not under the direct administrative control of the generating companies, and use of the funds is limited to legitimate decommissioning expenses.

- Ten reactors have completed decommissioning safely to either the point of license termination or the point where the remaining activities are limited to management of an Independent Spent Fuel Storage Installation (ISFSI). Currently, 18 commercial power reactors are in decommissioning, and several more will transition to this process over the next few years.

So who provides nuclear plant decontamination and decommissioning (D & D) waste management technology? Experts who have proven, long-term technical expertise and program guidance for the storage, processing and disposal of nuclear, chemical and defense waste as well as process and support decontamination & decommissioning of nuclear and hazardous material facilities.

Three essential areas expert Waste Technology D & D engineering labs must service - analytical, experimental and computer modeling. These areas must include the ability to provide:

Process & Safety Models & Analyses

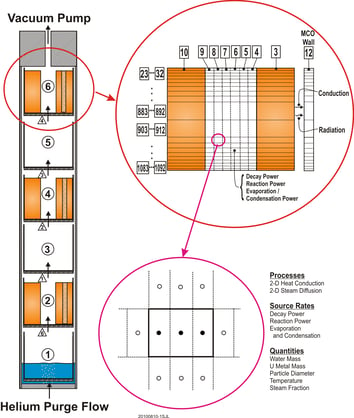

• FATETM software for process and facility design and safety calculations

• Facility flow, heat transfer and toxic/radiological materials transport

• Predict thermal stability during waste processing, shipping and storage

• Manage flammable and explosive hazards

• Facility fire analysis including toxic/radiological effects

• Chemical reaction propagation limits, including pyrophoricity

• Flammable gas generation by chemical reactions and radiolysis

• Aerosol generation, transport, deposition and removal

• Facility emissions and source terms for processes, accidents and D & D

• Emergency preparedness

Experimental Facilities for Hazard Quantification

• Lab-scale equipment for measuring chemical reaction, heat-up and pressurization rates

• Fluid systems testing, including waterhammer and flow regime

• Chemical and thermal behavior during waste processing, shipping and storage

• Gas and vapor flammability limits

• Vent design validation for managing flammable gas (H2)

• Dust explosion and hybrid dust/gas systems

• Kinetics of decomposition and chemical reactions

Proven Quality Assured FATETM Software

• Provides a consistent framework for modeling a wide dynamic range of common Department of Energy (DOE) and commercial fuel and waste applications including:

- Treatment, and storage of defense waste, including metal fuel, fuel debris and sludge

- Drying of commercial oxide fuel

- Reactor building fire modeling or fire PRA

- Hydrogen release, transport and flammability for post-Fukushima vulnerability assessment

• FATE software predecessor code HANSF won a DOE innovation award (FY2000)

• FATE is developed and maintained under a NQA-1 Quality Assurance Program

A nuclear waste technology service provider must provide Analytical Services. Operational nuclear facilities and legacy reprocessing sites have unique engineering challenges to address. Safe and efficient handling of nuclear and contaminated materials requires innovative technical solutions without which a basic engineering task can appear very complicated. Companies with more than 35 years of analytical, field and laboratory experience supporting complicated engineering projects are ideal. They offer comprehensive analytical solutions addressing all project aspects from fundamental process and safety evaluations to efficiency and technical basis justification.They also welcome First Of A Kind (FOAK) projects and thrive on thinking outside the box.

Analytical Areas of Expertise Must Include:

- Aerosol Physics

- Chemical Reaction Rates

- Criticality

- Emergency Response

- Engineered Basis

- Explosions

- FATETM Software

- Fire Modeling

- Flammability & Combustion

- Full Service (Analytical, Field Service & Laboratory)

- Integrated Process Evaluation

- Hydrogen Generation

- Radioactive Gas Transport

- Radiolysis

- Source Terms

- Thermal-Hydraulics

Examples of Projects Performed:

Sludge Transport and Storage Container

Developed and performed heat generation and heat transfer of a storage container containing radioactive sludge. Evaluations included the potential for criticality, hydrogen generation rates and proper vent sizing requirements. In addition, a safety evaluation was performed to assess the newly developed technology.

Interim Fuel Storage Integrated Evaluation

Fully integrated engineering evaluation of an interim storage facility. Evaluations included hydrogen generation, gaseous transport along with postulated off-site releases.

Hydrogen Accumulation - Post Fukushima

Playing a key role in the evaluation of the Fukushima accident including analyses of the accumulation of hydrogen in the reactor buildings.

Of course, the service provider should have a long list of customers served over those years including numerous operating as well as closed commercial nuclear power plants.

A nuclear waste technology service provider must provide Laboratory Services. Operational nuclear facilities and legacy reprocessing sites have unique engineering challenges to address. Comprehensive laboratory solutions address all project aspects from fundamental process and safety evaluations to efficiency and technical justification.

Laboratory Capabilities Must Include:

- Aerosol Physics (entrainment, resuspension, etc.)

- Calorimetric

- Chemical Reaction Rates

- Chemistry Interactions (i.e. sodium/water interactions)

- Dust Explosion

- Evaporation Rates

- Flammability Limits

- Heat & Gas Generation Rates

- Heat Flux

- Hydrogen Generation & Ignition

- Ignition Criteria

- Mechanical Stability of Gas-Generating Sludge

- Physical Properties (density, heat capacity, etc.)

- Reaction Rates

- Pressurization Rates

- Safety Relief Vent Sizing

- Stability

Examples of Projects Performed:

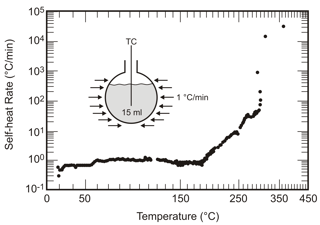

“RED OIL” Thermal Stability

Tri-n-butyl phosphate (TBP) saturated with concentrated nitric acid (HNO3) can form two-layer organic/aqueous morphology in solvent extraction system evaporators and tanks. The organic phase reacts exothermically and under certain conditions can lead to a thermal runaway. Testing IS performed to determine the response of “RED OIL” under various process conditions.

Organic Nitrate Evaluation

High level waste streams can include organic-bearing sludge and salt cake waste. Organic complexants like sodium acetate along with oxidizers like sodium nitrate present the potential for spontaneous runaway chemical reactions (thermal instability). Several oxidizers have been tested to determine their potential for an exothermic runaway reaction.

Dust Explosion Testing

Performing combustible dust explosion severity tests determines the extent of protection needed in the process. Numerous testing protocols can be evaluated. As an example, testing can be performed to determine the maximum explosion overpressure (PMAX) generated during an ignition event of a flammable mixture, as well as the deflagration index (KG) which is the maximum rate of pressure rise normalized to the vessel volume. These parameters are used to help pressure rate a vessel for containment purposes or to be used to design an explosion relief system.

Evaluation of organic-nitrite mixture

Nuclear Power Plants are decontaminated and decommissioned effectively with recognized proven experts who provide both expertise and experience to effectively generate solutions to complex engineering problems. The best draw upon analytical, field service and laboratory capabilities together to deliver full service solutions. Those companies with more than 35 years of success servicing both the nuclear and chemical industries have acquired broad expertise and continue education processes and patents to support complex engineering problems.

For more information, please contact Kris Fauske, 630-887-5246, kfauske@fauske.com, www.fauske.com