MARS – A Powerful Severe Accident Modeling Tool for 27 Years

By Nick Karancevic, Sr. Nuclear Engineer, Fauske & Associates

When one hears reference to Mars, the mind often travels to thoughts of the second smallest planet in our solar system. Fauske & Associates, (FAI) has a Mars of its own – but it isn’t a planet. In this case, the Modular Accident Response System (MARSTM) is a unique software suite designed to assist with nuclear power related severe accident analysis.

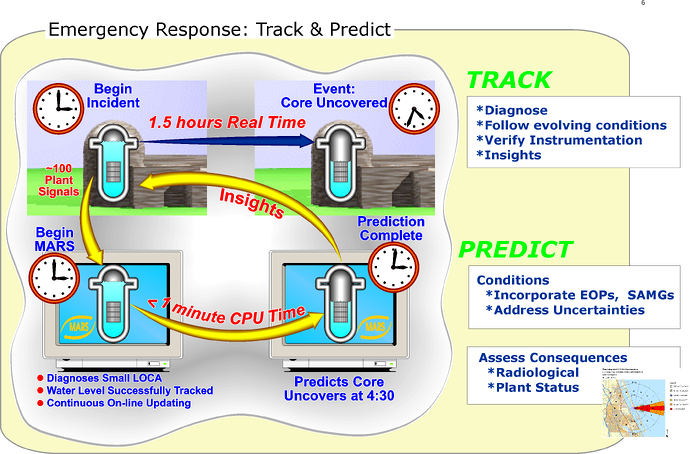

First introduced in 1987, MARSTM was developed by FAI as an engineering tool to monitor and predict potential future states of nuclear power plants under either abnormal, or accident conditions. It uses dynamic sets of plant data to initialize the highly benchmarked, world class thermal-hydraulics Modular Accident Analysis Program (MAAP) software to track plant data and to perform multiple faster than clock time predictions of potential plant response as a result of projected hazardous conditions. MAAP is a product of the Electric Power Research Institute (EPRI), developed and maintained by FAI.

Understanding the consequences of abnormal and severe accidents in the nuclear power industry has always been a critical part of maintaining safe and effective operations. The importance of understanding potential consequences was brought front and center in the aftermath of the 2011 Fukushima Daiichi Nuclear Power Plant event.

The highly customizable nature of the MARS software makes it a useful tool for utilities to perform very specific analysis of potential scenarios. MARS is a versatile software, able to operate online (i.e. connected to a plant process computer), or offline. In online mode, it gathers information from the plant process computer to obtain a view of plant conditions, including temperatures, pressures, and water levels, throughout the primary, secondary, and containment systems. The software has two key functions: tracking and predicting.

The MARStracker can initialize a plant simulation at any time using a limited set of dynamic plant data. Once initialized, it provides detailed real-time information about the current plant state, including the ability to evaluate and monitor specific plant parameters, such as fuel status, system status, and hydrogen concentrations.

MARS predictors perform multiple faster than real-time predictions of potential plant states based upon the current understanding of plant conditions. These predictions can improve response time during an actual event, and provide valuable insight regarding whether it is better to shelter, or to evacuate. It can also model operator actions and plant accident management procedures, and it can address uncertainties with model assumptions.

A more detailed list of the features of the software include:

- Solid engineering simulations of nuclear power plants based on the industry leading MAAP code

- Ability to use “live” online plant data for engineering simulations and/or offline data

- Software simulation models to represent operator actions in accordance with plant procedures

- User-friendly graphical user interface representing the nuclear power plant

- Engineering models for emergency response activities (for example, off-site radiation dose assessment)

MARSTM can provide:

- Accident management support

- Offers educated, faster than real time response predictions during emergencies

- Instrumentation verification

- Tracks plant data to simulate plant instrumentation readings and therefore provide verification of instrumentation readings

- Emergency Preparedness/Drill Development and Scenarios

- Estimates timing and magnitude of possible releases of radiation

- Provides dynamic interactive simulations allowing participant input

- Plant Monitoring

- Offers engineering evaluations of the plant response

- Assesses when procedural limits (at power or shutdown) could be exceeded

- Reactor accident response training simulations

- Accurately represents the plant status during accident conditions

MARS undergoes extensive testing prior to its release to a customer. The testing involves using real plant accident data along with computer simulations of potential accident conditions. The MARS software is then initialized and tracks the evolving plant data during key points of those real or simulated scenarios. The MARS results are then compared the actual or simulated data to establish confidence in the tool. MARS development is considered complete when the results generated by MARS and actual/simulated data are consistent.

As you can see, with a solid 27 years of experience, MARS is a very relevant and powerful engineering tool that can be used to assist in the emergency response to a severe accident, or aid in mitigation of upset conditions through engineering simulation.

For more information regarding MARSTM and other severe accident analysis, contact Nick Karancevic at (630) 323-8750 or Karancevic@fauske.com