This article is Part II of https://www.fauske.com/blog/3-ways-to-protect-your-electrical-cable-assets-part-1

Cable assets can be diagnosed in many ways ranging from simple electrical tests such as continuity checking, to sophisticated laboratory techniques such as nuclear magnetic resonance (NMR) evaluations. The most appropriate diagnostic technique depends upon the reason for doing diagnostics; there are many reasons for performing cable diagnostics. For this discussion, the reason for performing cable diagnostics is for cable aging management and to assess when to repair and/or replace aging cable.

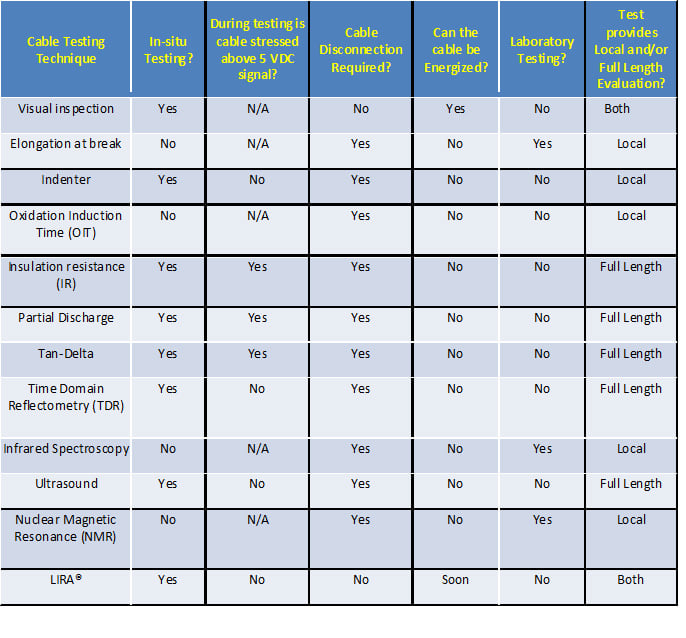

The following table summarizes the major types of cable diagnostic techniques:

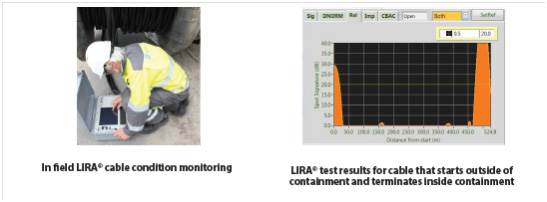

Although there are many cable diagnostic techniques, as seen from the table, the one cable testing technique that stands out from all the rest is the Line Resonance Analysis (LIRA). LIRA is the unsurpassed technique for cable diagnostics because LIRA does not overstress the cable while testing because it only uses a 5 VDC frequency modulated signal. Unlike most other cable testing techniques, to perform a test, LIRA does not require the cables to be disconnected; only the breaker needs to be open. LIRA provides the ability to evaluate cables locally (to identify degraded cable areas) along with performing a full length (overall) assessment of the cable. Fauske & Associates is the North American LIRA representative for the nuclear power and facility industries. We sell the LIRA test equipment, provide LIRA training, calibrate the LIRA device and can provide on-site testing services.

LIRA is an easy to use cable testing technique, developed in Europe. The process for running a LIRA test involves grounding the cable to assure the cable is not energized, then connecting the LIRA probes to 2 metal cores and starting the LIRA data collection software. The entire process is completed in minutes. Once the data is captured, it can be analyzed. The analysis software included with LIRA provides locations along the cable that have potential issues (degraded cable, bad splices, etc.) along with a global evaluation of the cable performance. All of the collected data is stored in a data base for future monitoring and evaluation.

Read part 3 here: https://www.fauske.com/blog/3-ways-to-protect-your-electrical-cable-assets-part-3

Next time, in Part III, we’ll discuss monitoring your cable assets. For more information regarding cable aging, health and testing, please email us at info@fauske.com