Chemical Testing Services That Will Save You Money

Adiabatic Calorimetry

Combustible Dust Hazards

Gas & Vapor Flammability

Reaction Calorimetry

Thermal Stability

UN-DOT Testing

It seems like common sense to test your materials on a small scale first to see what occurs before you invest in the bigger, full scale process. You'd be surprised how many times that does not happen. In our perpetual work haste and budget constraints, we often skip steps such as pre-testing that not only saves time and money in the long run, but is vital to keeping us safe.

Of interest to note, the difference in online searches for "chemical testing" versus "chemical PROCESS testing". It's worth mentioning here that both can save money - first, by determining what methods will be most efficient and safest and second, to what scale. So, a large part of what we are talking about here is the need for PROCESS testing.

The types of tests and safety programs listed above can go a long way by providing a comprehensive Process Safety Management (PSM) program that keeps your facility in line, on time and on budget - while most importantly - safer. The types of tests listed above also need to be done first in order to be able to set up the methodology for the chemical tests run regularly thereafter. A comprehensive PSM program will dictate the baseline for safety operations and establish the schedule for checking regularly.

How do chemical process testing and safety procedures save the organization money?

1. Chemical Testing and Safety Procedures Increase Performance Quality and Operating Efficiency

A study of 19 manufacturing firms supports the theory that good safety performance is related to good operating performance in "A Data-Based Evaluation of the Relationship Between Occupational Safety and Operating Performance" (PDF) Journal of SH&E Research Vol.4, No. 1 (Spring 2007).

Per reports from the American Institute of Chemical Engineers (AICHE): The Business Case for Process Safety: "COMPANIES that implement effective process safety programs receive a windfall benefit every year. This income shows up on the bottom line in the form of the major incident that DID NOT occur. Process safety provides unparalleled capacity for enhanced risk reduction. Your company’s risk exposure is reduced in the following areas when well-founded process safety systems are in place.

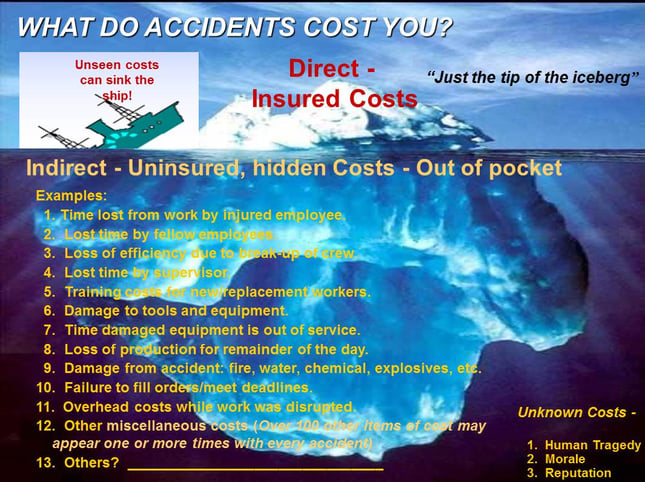

■ Lives are saved and injuries are reduced — Both the personal impact of human loss and cost of deaths or injuries are painful. A solid process safety program can help prevent these costs.

■ Property damage costs are reduced — In the U.S., major industrial incidents cost an average of $80 million each.

■ Business interruptions are reduced — These losses can amount to four times the cost of the property damage from an incident.

■ Loss of market share is reduced — After an incident, this loss continues until the company’s reputation is restored. Adverse publicity and negative public image can have insurmountable effects.

■ Litigation costs are reduced — These are unavoidable after an incident and can total five times the cost of the regulatory fines.

■ Incident investigation costs are reduced — Investigating an incident and implementing corrective actions can cost millions of dollars.

■ Regulatory penalties are reduced — For many incidents, a fine after litigation can total 1 million dollars or more.

■ Regulatory attention is reduced — A major incident usually results in increased regulatory audits and inspections. Any of these items can easily put a smaller company out of business.

How does increased risk reduction capability enhance your company? Most companies participating in this study observed significant reductions in injury rates due to implementing high quality process safety programs.

■ One company achieved a 50% reduction in injuries and fatalities resulting from major incidents (compared to overall industry averages). This saved them over $5 million per year and an additional savings of $3 million per year in reduced worker compensation costs.

■ Incidents cause operational interruptions. If your plant is not idle due to an incident, you are making product and the business can flourish.

■ Incidents divert corporate management’s attention from long-term business planning. When these managers have to stop and deal with incidents and other crises, it can distract their ability to concentrate on sustainable growth.

■ Your corporate reputation and legacy are protected for future generations."

According to "The Business Case For Safety: Adding Value and Competitve Advantage" from OSHA, .jpg?width=427&name=business_case_safety_20050621%20(1).jpg) bottom line metrics are significantly affected by safety in terms of both employee and management morale. Explaining, encouraging, and rewarding proper behaviors is motivating and empowering which translates into skills and efficiency = production increases.

bottom line metrics are significantly affected by safety in terms of both employee and management morale. Explaining, encouraging, and rewarding proper behaviors is motivating and empowering which translates into skills and efficiency = production increases.

"Providing a safe workpace is key to meeting business objectives. Protecting reputation and attracting and retaining high potential employees" are all part of safety's role. And, the cost/benefit cases for safety must include direct and hidden (such as high turnover rates and costs avoided in accidents, etc).

2. What about those tests/programs mentioned above? Why do each of them matter?

- Adiabatic Calorimetry & Relief System Design - Safe scale up is key. Adiabatic calorimeter testing provides data for relief system design, safe scale-up of chemical processes, and changes to process recipes. Safe process design requires knowledge of chemical reaction rates, character and energy release - all of which can be obtained from a low phi-factor adiabatic calorimeter which provides thermal data required for safe scale-up of chemical processes and changes to process recipes. A variety of process upset conditions can be tested to quantify hazards identified by a PHA or HAZOP study. The low phi-factor (or thermal inertia) allows the heat and gas generation rates to be measured and directly applied to the process scale, which leads to appropriately designed emergency relief systems.

- Combustible Dust Hazards Analysis (DHA) Analysis - Combustible/Explosible dust hazards are common in industry and have gained additional exposure due to the OSHA Combustible Dust National Emphasis Program (NEP) which was re-issued as a result of the fatal accident at Imperial Sugar. Testing services related to Dust Hazards Analysis (DHA) include characterizing, preventing and mitigating dust explosion and fire hazards. These services include combustible dust testing in labs, onsite assessments, OSHA and NFPA compliance assistance, audit preparation, training, ignition source evaluation and vent sizing calculations.

- Failure Analysis - Train employees to recognize chemical evaluations of the base material, surface deposits, crack deposits and weld metals. Work with them to outsource regular specialized testing using energy‐dispersive spectroscopy techniques, X‐ray diffraction and/or wet chemical analysis techniques. For detailed surface characterization, for example, use a testing lab that uses a SEM‐EDS equipped with a focused ion beam mill.

- Gas & Vapor Flammability - One of the largest causes for loss in process industries for both equipment and life is fire. The enormous volume and frequency of use of flammable and combustible liquids and gases handled worldwide implies that the risk of industrial accidents is great.

- Reaction Calorimetry - One of the keys to safely scaling up a chemical process is managing the energy or heat flux that the intended chemical reaction produces, especially when that chemical transformation is exothermic in nature. When considering process scale-up whether the heat is removed via a jacket, a condenser, or a side loop heat exchanger in the plant reactor or partially allowed to heat up the mass, it is imperative to balance the cooling capacity at scale versus the projected heat flux rate and understand the total energy available due to the desired reaction should that cooling fail.

- Risk Management Services (including Process Safety Management PSM, PHAs, etc) - A complete Risk Management Services program includes Combustible Dust Hazard Assessment (DHA) Explosion and Fire Hazard Evaluation, Process Hazard Analysis (PHA), Hazard Identification Risk Analysis, Consequence Analysis, Safer Process Scale-up, Process Safety Management (PSM) Program Development, and Relief System Design Review.

- Thermal Stability - Often material safety data sheets refer to the thermal stability as an intrinsic property of a substance or mixture. In fact, this is an oversimplification of a concept that must be defined in a more comprehensive way. Thermal hazard / stability testing collects reaction rate data and assesses whether a specified quantity of material can be used in a way such that runaway reactions are avoided. This is important when considering processing, long-term storage, or shipping of a material.

- UN-DOT Testing - When goods are to be transported, there are many regulations that need to be followed in order to assess and classify the hazards associated with the specific material. This can be an important factor in the design and commercialization of a specific good. Slight changes in the composition of the material may not change the overall end use of the product but could possibly result in a change in its hazard classification.

ROI...production time....morale....efficiencies...safety - investment now and continuously will increase returns overall. Don't take short cuts in chemical safety.

For more information, please contact us at info@fauske.com.